9. Drill a 1 1/2" hole through the mounting board at point C. Use a file to remove burrs from around all the holes after

drilling so that the mounting base will sit level on the mounting board. Reinstall the mounting board on the turntable.

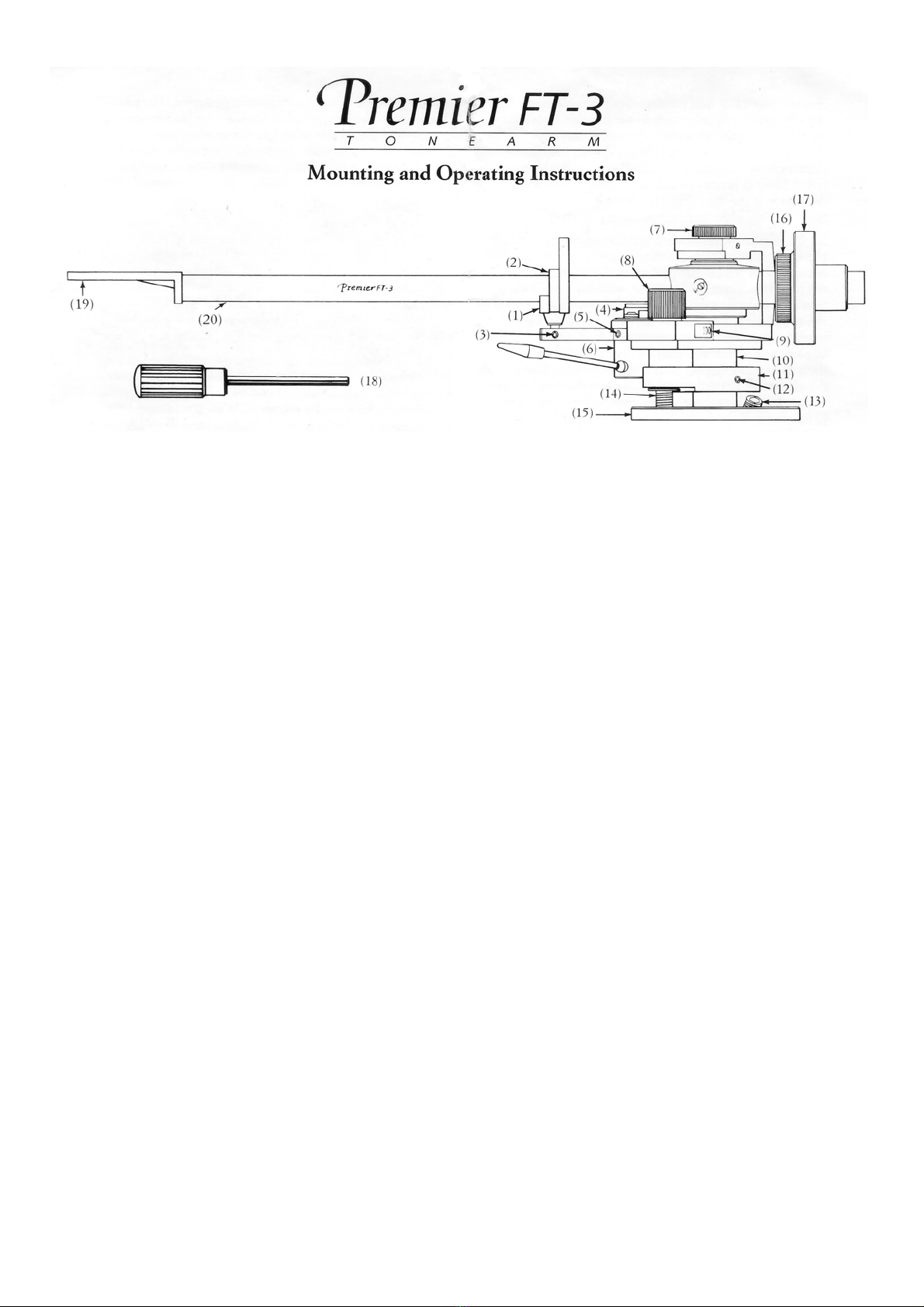

Mounting the Tone Arm

10. Separate the elevation collar (with elevation screw attached) from the mounting base by rotating the elevation

screw counterclockwise. These two parts may be packed individually in the box and need not be separated. Set the

elevation collar aside. Position the mounting base over the cut-out area on the mounting board so that the circular

cut-away on the lip of the base faces forward. The mounting base should now fit into the cut-out on the mounting

board, and the screw holes at points D1 through D3 should line up. If the holes were not drilled accurately, it may

be necessary to remove the mounting board from the turntable and use a file to enlarge the cut-out for a proper fit.

11. The mounting base should now be bolted to the mounting board using the hardware provided. The Phillips head

screws are provided for use with thin mounting boards, and the longer allen head screws are used for thicker

mounting boards. Insert the appropriate screws from the top at points D 1 through D3. Mount washers and nuts

from the bottom. Finger-tighten the nuts.

12. Remove the stainless steel finger lift from the package. Use of the finger lift is optional. If used, it should be placed

on top of the headshell and secured in place with the cartridge mounting hardware. Whenever possible, the stylus

guard should be kept on the cartridge to protect the fragile stylus assembly. Loosely mount the phono cartridge to

the headshell and attach the tone arm wires to the phono cartridge. The tone arm wires are marked with the

standard color code: Red R+, Green R-, White L+, Blue L-.

13. Before the tone arm can be inserted into the mounting base, the brass-locking piston (which is located inside the

center hole) must be retracted. With your finger or a pencil, press the locking piston back toward the VTA locking

set screw If the locking piston still protrudes into the center hole, rotate the VTA locking set screw a half turn or

more counterclockwise to allow the piston to be pushed further back.

14. Place the arm into the mounting base, letting it slide down as far as it will go. Tighten the VTA locking set screw

with the 3 mm hex key that has a knob attached to it. Measure the horizontal distance between the center of the

spindle and the pivot point of the arm. Adjust the position of the base until this distance is 221.7 mm. Tighten the

two accessible base mounting nuts to fix the position of the mounting base. Recheck spindle-to-pivot distance to be

sure that the mounting base did not move when the mounting nuts were tightened. Loosen the VTA locking set

screw and remove the arm from the mounting base. Now firmly tighten all three base mounting nuts.

15. Position the elevation collar so that the attached elevation screw points down and over the threaded hole in the

mounting base. Use the elevation adjustment tool to screw the elevation screw into the hole in the mounting base.

Continue turning the elevation screw clockwise until the bottom of the elevation collar is approximately 5 mm from

the top surface of the mounting base. Align the main (16 mm) hole in the elevation collar with the center hole in the

mounting base. Check and adjust, if necessary, the position of the locking piston as described in section 13. Insert

the tone arm pillar through the elevation collar and into the mounting base. Rotate the arm in the hole until the

chrome cue cylinder lines up with the circular cutaway on the mounting base. Adjust the height of the tone arm so

that the arm tube will be parallel to the platter when the stylus is on a record. Tighten the VTA locking set screw on

the mounting base to secure the arm in the proper position. Tighten the elevation collar lock screw.

Tone Arm Adjustment and Operation

16. If your turntable has not been leveled previously, level it now Twist the counterweight onto the back of the tone arm.

For cartridges weighing up to 8 grams, only the main counterweight is necessary. For cartridges between 8 and 14

grams, the accessory counterweight should be fastened to the back of the main counterweight. To secure the

accessory counterweight, tighten the set screw. Be sure the accessory counterweight rests firmly against the back

of the main counterweight disk. Set anti-skate force to zero by turning the knob on the right side of the arm pivot

completely counterclockwise. Remove the stylus guard from the phono cartridge. Unlock the arm rest. Ignoring the

calibrations on the indicator dial, roughly balance the arm by moving the counterweight backward and forward until

the arm "floats" parallel to the platter. Return the tone arm to the arm rest and lock in place. Note that the stylus

force indicator ring has two scales. The inner scale is calibrated for use when both the main and accessory

counterweights are used. Rotate just the stylus force indicator dial (not the counterweight) until the 0 lines up with

the white line on the counterweight support shaft. Grasp the entire counterweight; rotate it and the indicator ring

counterclockwise until the 1 gram mark on the appropriate scale lines up with the white line.