4

Summit-Hydraulics.com

Notes:

WARNING: DO NOT LOOSEN OR REMOVE ANY FITTINGS, COUPLERS OR VALVE

CARTRIDGES WHILE THE SYSTEM IS UNDER PRESSURE OR WHILE A LOAD IS

BEING HELD UP BY THE VALVE.

Pressure and return are determined by the position of the tractor lever

Must be used with the tractor remote outlet. Valve does not control, but selects

circuit.

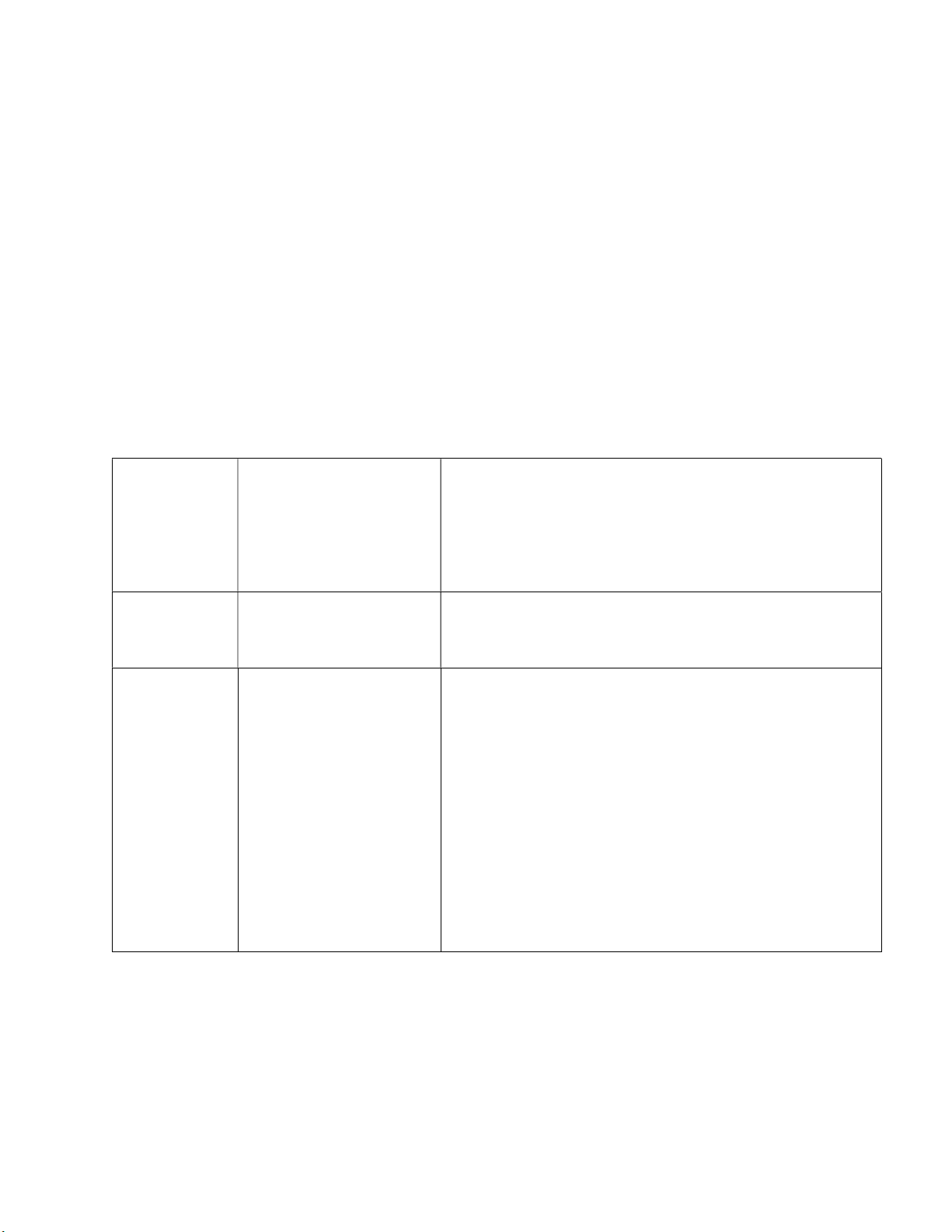

Troubleshooting:

The valve will

not work

Low or no

voltage between

the coil terminal

and top coil nut

Not properly

grounded

Use a voltmeter to check between the coil

terminal and the outlet. There should be at

least 11 volts

Check coils for magnification. To check, place

a small metal object on top of the coil nut.

Check ground connection. Ensure there is

metal to metal contact for a secure ground.

Valve was

previously

working

Blown Fuse

Damaged Wire

Bad Switch

Check hydraulic connections to see if it was

installed correctly. See installation guide for

proper instructions.

Inspect tips and couplers for proper mating

Only one of

the two

circuits is

working

Coil may be bad

Cartridge may

be

contaminated

Exchange wires between the working coil and

the non-working circuits

If problem persists exchange coils from circuit

one to circuit two

If problem changes to opposite circuit, the coil

may be bad and need to be replaced.

If the problem remains on the same circuit,

exchange the cartridge from circuit one to

circuit two. If the problem changes to the

opposite circuit, the cartridge may be some

contamination.

Visually inspect the cartridge, if no

contamination is found the cartridge could be

bad and need to be replaced.