Before each use:

1. Inspect the cable for kinks and frays. If kinked

or more than 3 wire strands are broken (small

wires) do not use the lift until the cable has

been replaced.

2. Make certain winch operates freely and cable is

not tangled on the winch drum.

3. Inspect mast, legs, and base for bends.

4. Make sure caster wheels move freely.

Recommended Inspection Every 6 Months:

1. Inspect cable for frays and kinks (see point 1

above)

2. Make certain winch works freely and that there

are no loose or damaged parts.

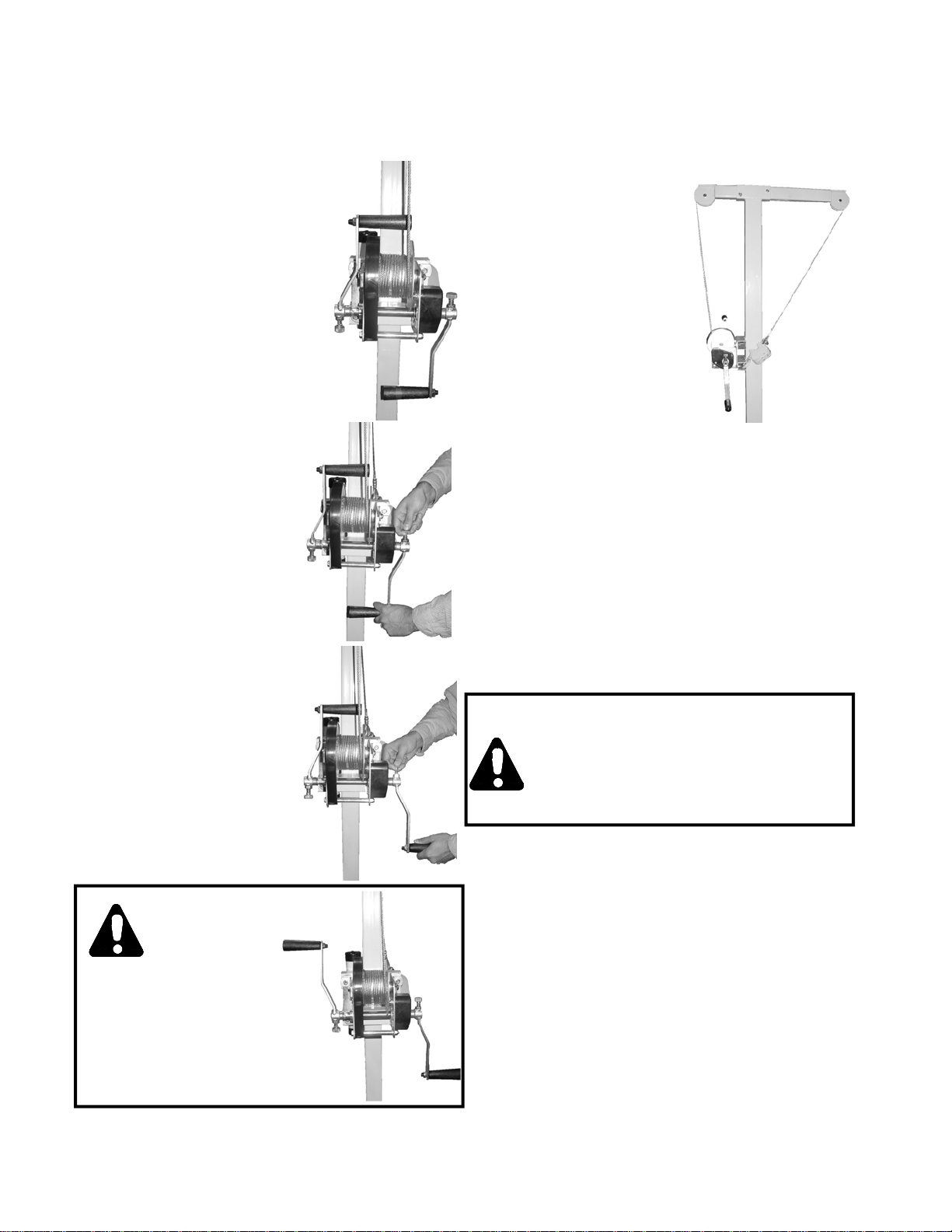

Winch Maintenance:

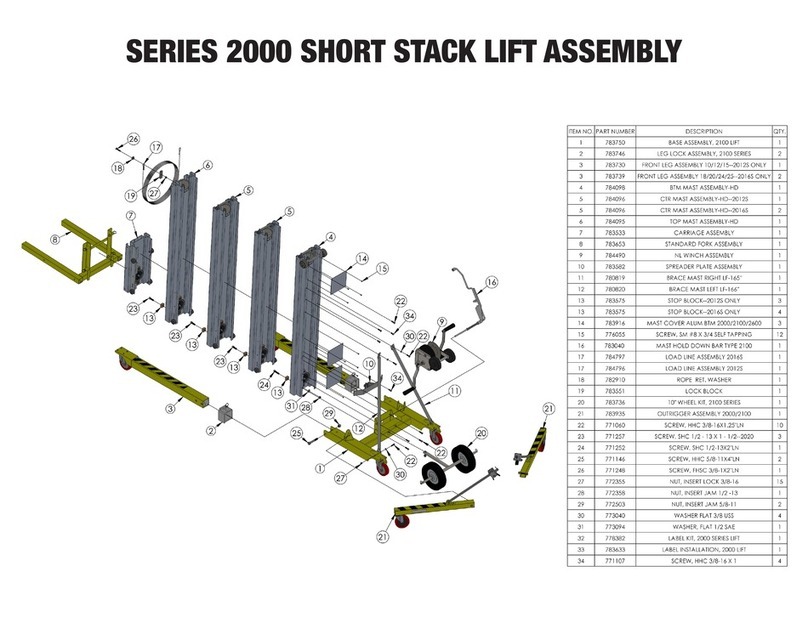

1. Refer to the winch assembly drawings in this

Operators Manual.

2. Be sure that the winch cover is on the winch.

3. Check ratchet dog and brake ratchet for wear.

If any wear is visible, replace the part.

4. Inspect gear teeth for wear. If there is no sign

of visible wear, brush teeth with 50-wt. Motor

oil.

5. For proper brake adjustment see

“Troubleshooting” section on page 9.

Replacing the Cables:

A. Load Lifting Line

1. Lay Fab-Mate across supports with the winch

facing up.

2. Remove the gear cover.

3. Disengage load ratchet dog and pull wire rope

off of drum.

4. Loosen set screw on drum and pull wire rope

out of keeper.

5. Pull Load Line out through front of Tee head.

6. Reverse for installing new Load Line.

General Maintenance:

1. Check winch handle for wear or bends.

2. Examine all bolts and nuts to be sure they are

tight.

3. Legs, braces and base should be dent free and

damage free.

4. Check pulley housings for damage

(indentations) which can restrict the rotation of

the pulleys.

5. Make sure all lines are seated in all pulleys and

that pulleys rotate without obstruction.

7. Make sure caster wheels rotate freely and are

undamaged.

MAINTENANCE INSTRUCTIONS