6

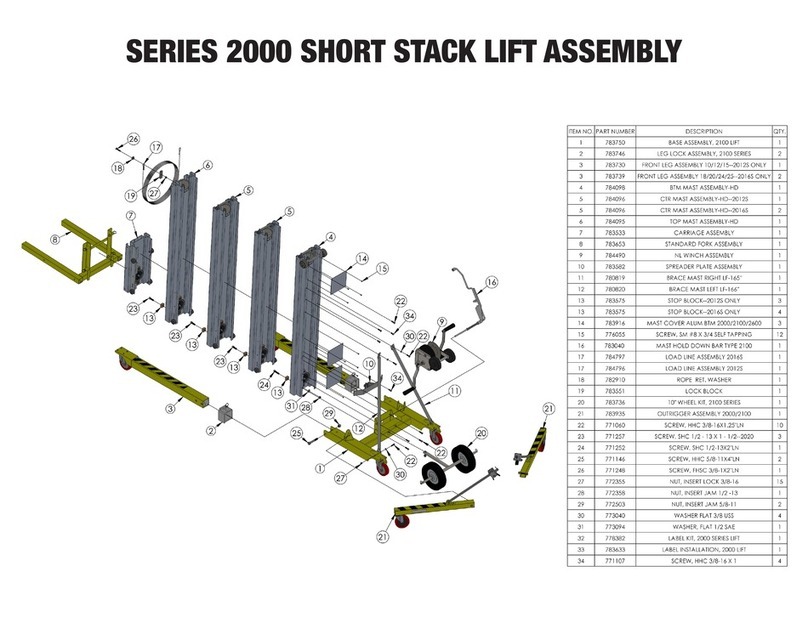

ASSEMBLY INSTRUCTIONS

1. Turn base upside down.

2. Insert the four casters into the base legs.

3. Secure the casters into the base by

installing the four supplied setscrews into

the base legs and then tighten with allen

wrench. Ensure screw is tightened onto

caster stem.

4. Turn base over and lock caster brakes.

5. Insert mast assembly into base assembly

socket with winch to rear of base, rear

being the side of base with the shorter

legs.

6. Ensure base latch is engaged.

7. Release tension on lifting cable by turning

the lower shaft on the winch counterclock-

wise. Remove clevis pin and clevis. Now

lower the lift cable so end of cable can be

reached by operator.

8. Attach counterweight and line shackle

directly to loop on end of lift cable.

OPERATING PROCEDURE

WARNING

Operators should be thoroughly

familiar with the preceding safety

precautions before attempting to

operate this equipment.

NOTE: Always lower mast assembly to the

lowest possible position prior to moving unit.

1. MOVING ROUST-A-BOUT TO

WORK AREA (NO LOAD)

1. The load line shackle

should be attached to

winch mount bracket

prior to transporting unit

to prevent the cable

from swinging and

striking operator or

bystanders.

2. Attach winch handles to

both sides of winch,

which will allow them to

be used as a handlebar to steer the unit.

WARNING

Roust-a-Bout should only be

operated on level and smooth

surfaces to avoid tipping and

possibility of operator injury.

3. Release caster brakes.

4. Grasp winch handles and make a

forward “S” motion to align casters for

forward movement to work area.

2. MOVING ROUST-A-BOUT TO

WORK AREA (WITH LOAD)

1. When the Roust-A-Bout is used to

transport a load, the load should be

placed on the base legs for positive

control of the lift.

2. The loaded Roust-A-Bout should only be

moved in the forward direction,

whenever possible.

3. Repeat steps 2, 3 and 4 from previous

section.

3. Elevating Mast

NOTE: Mast should be elevated to

required height prior to lifting any load over

500 lb (225 kg).

WARNING

“Guy Lines” must be used anytime

mast is elevated over 20 ft (6.1 m)