SUNERGY USA WORKS LLC

Installers must know the possible danger of death or serious bodily injury.

Do not cut the connection wire under the loading.

Do not modify solar panel, move any labels or other parts.

Do not use chemicals on solar panel surfaces.

Do not expose solar panels to sunlight that is concentrated with mirrors, lenses or similar means.

Solar panel installation must obey the local law, even it should get the Construction Licence.

Do not wear the things, such as rings, metal jewelry, diamond jewelry or tools. which can damage

the surface of module during the installation process.

5. SAFETY REGULATOINS REGARDING INSTALLATION OF SOLAR POWER SYSTEMS

6.1 Take the following precautions before starting work

Plan the job and visit the site before starting work. On site, do not work along. Always work with at

least one other person. Inspect power tools before using them

6.2 Observe safety regulations during installation

Do not wear metallic jewelry, which may cause electrical shock

Keep the back side of solar panel surfaces free of foreign objects

Completely cover solar panel with opaque materials when wiring to halt productions of electricity.

6. REQUIRED INFORMATION

Artificially concentrated sunlight shall not be directed on the panel.

“Rated electrical characteristics are within 10 percent of measured values at Standard Test

Conditions of: 1000 W/m², 25 °C cell temperature and solar spectral irradiance per ASTME

892 or irradiation of AM 1.5 spectrum.

Under normal conditions, a photovoltaic panel may experience conditions that produce

more current and/or voltage than reported at Standard Test Conditions. Accordingly, the

values of Isc and Voc marked on should be multiplied by a factor of 1.25 when determining

component voltage ratings, conductor capacities, fuse sizes and size of controls connected

to the panel output. Refer to Section 690-8 of the National Electric Code for an additional

multiplying factor of 1.25 which maybe applicable.

8. POINTS TO CHECK WHEN SELECTING THE INSTALLATION LOCATION

8.1 The direction toward the equator to install solar modules, if possible. Installations facing

east and west are also possible, although the amount of power generated will be lower.

8.2 Install in a location that has good sun exposure throughout the year. Less power is

generated in shaded locations.

8.3 The output of a series string of solar panels is connected to the input of the inverter.

Always install solar panels so that all elements of the array receive the same amount of

sunlight.

8.4 It may not be possible to install solar panels in regions where maximum snow accumulation

exceeds the maximum allowable load.

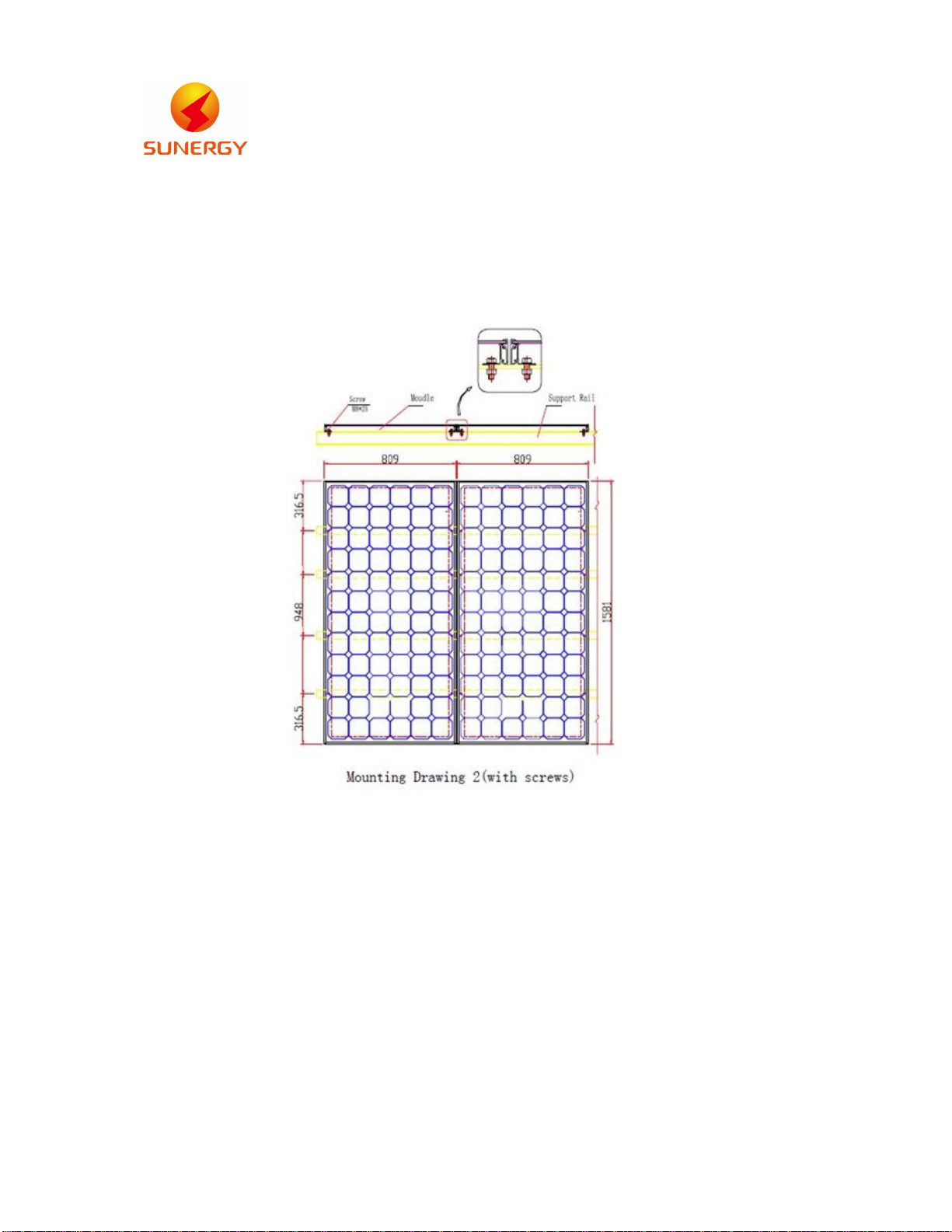

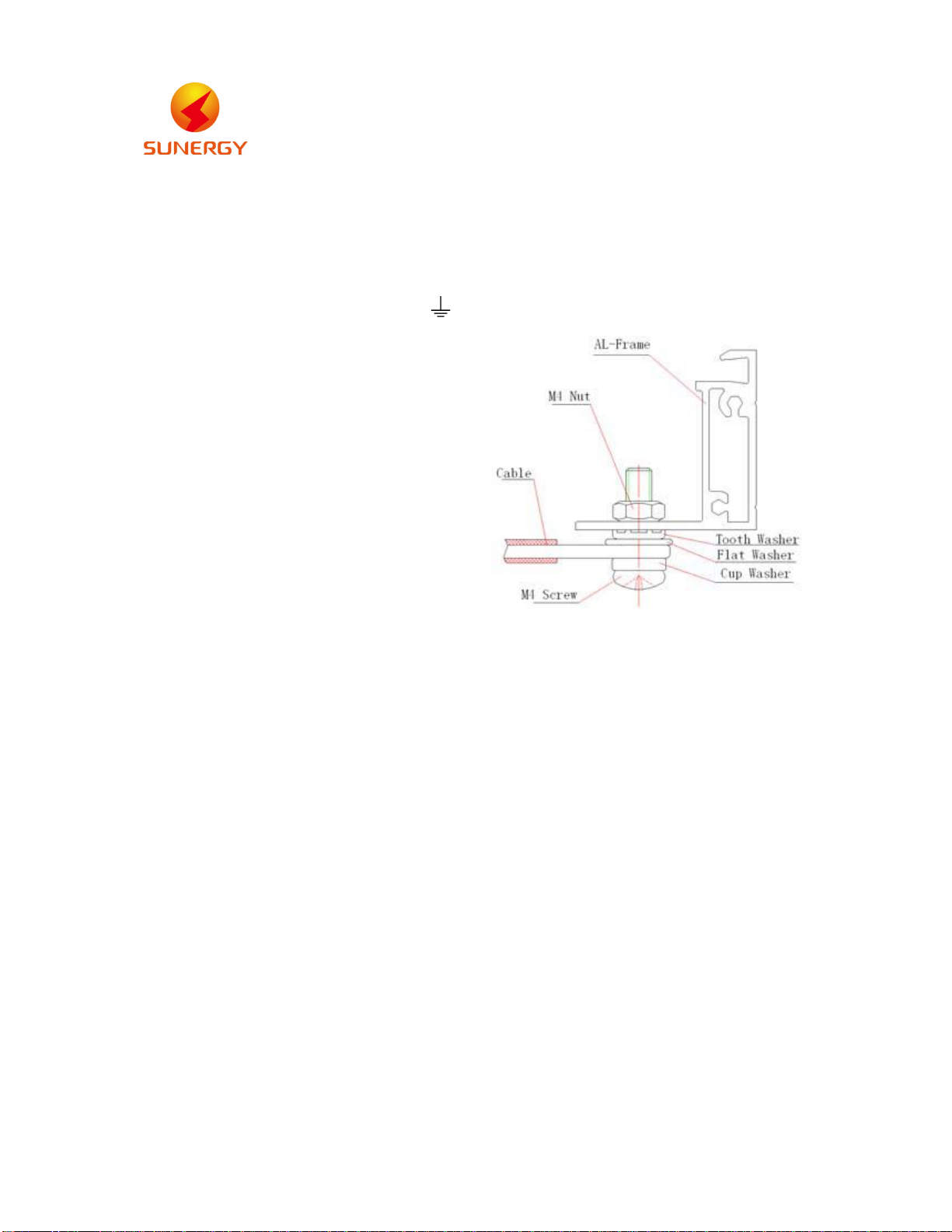

9. MOUNTING AND NOTES

The module frame is made of anodized aluminum, and therefore corrosion can occur if the

modules is subject to a salt water environment with contact to a rack of another type of

metal (Electrolysis Corrosion). If required, PVC or stainless steel washers can be placed