2

Contents:

INTRODUCTION & SAFETY INFORMATION.......................................................................................................3

KIT CONTENTS..................................................................................................................................................4

TOOLS REQUIRED FOR INSTALLATION.............................................................................................................4

OTHER ITEMS ...................................................................................................................................................4

STORAGE & HANDLING PRECAUTIONS............................................................................................................5

INSTALLATION OVERVIEW ...............................................................................................................................5

SOLAR PANEL LOCATON...................................................................................................................................6

ROOF SURFACE PREPARATION ........................................................................................................................6

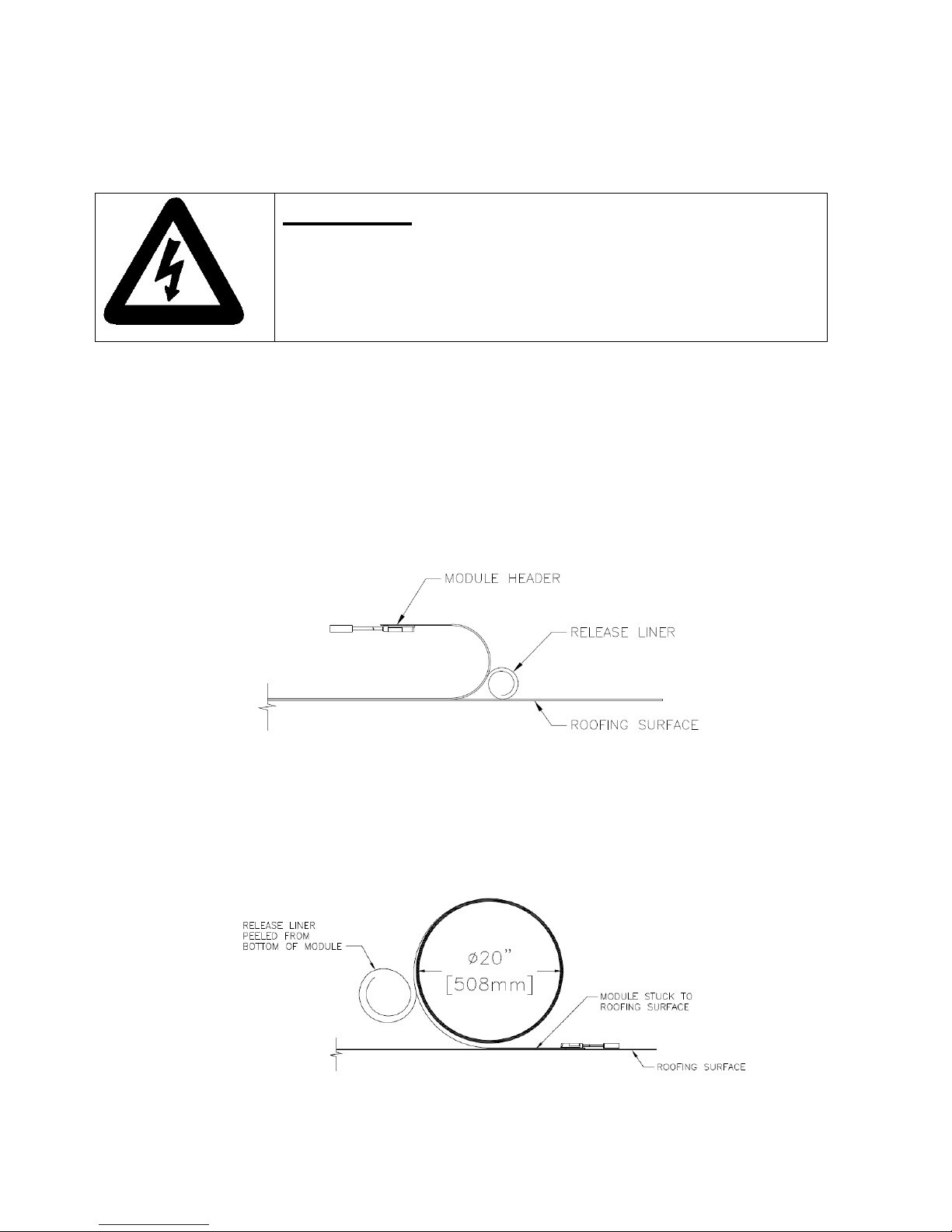

INSTALLING THE SOLAR PANELS ......................................................................................................................8

INSTALLING THE EDGE TRIM............................................................................................................................9

SPECIAL ROOF TYPES......................................................................................................................................12

LOCATING THE SOLAR CHARGE CONTROLLER...............................................................................................12

ROUTING THE CABLE......................................................................................................................................13

CONNECTING THE WIRING ............................................................................................................................17

MAINTENANCE...............................................................................................................................................18

APPENDIX.......................................................................................................................................................20

Technical Support.......................................................................................................................................20

About The Solar Charge Controller............................................................................................................20

Charge Controller Specications: ...............................................................................................................21

Solar Panel Specications:.........................................................................................................................21

Installaon Summary Chart .......................................................................................................................22

WARRANTY REGISTRATION...............................................................................................................................................19

DOCUMENT NO. 1000564 REV. E

Global Solar® PowerFLEX™ Mobile Limited Warranty................................................................................ 23