Sunex Tools SX233A User manual

SX233A: Parts Breakdown & Operating Manual 1 05/12/10

Operating Instructions • Warning Information • Parts Break down

Max. Free Speed ............ 20,000 RPM

Wheel Size .......................................3"

Weight.......................................1.6 LB

Length .........................................7.83"

Average Air Consumption....... 5 CFM

SX233A

UTILITY

CUT-Off

TOOL

Air Inlet................................. 1/4" NPT

Recommended Air Pressure....90 PSI

Sound Level............................ 93 dBA

Air Supply Hose Size.............3/8" I.D.

SPECIFICATIONS

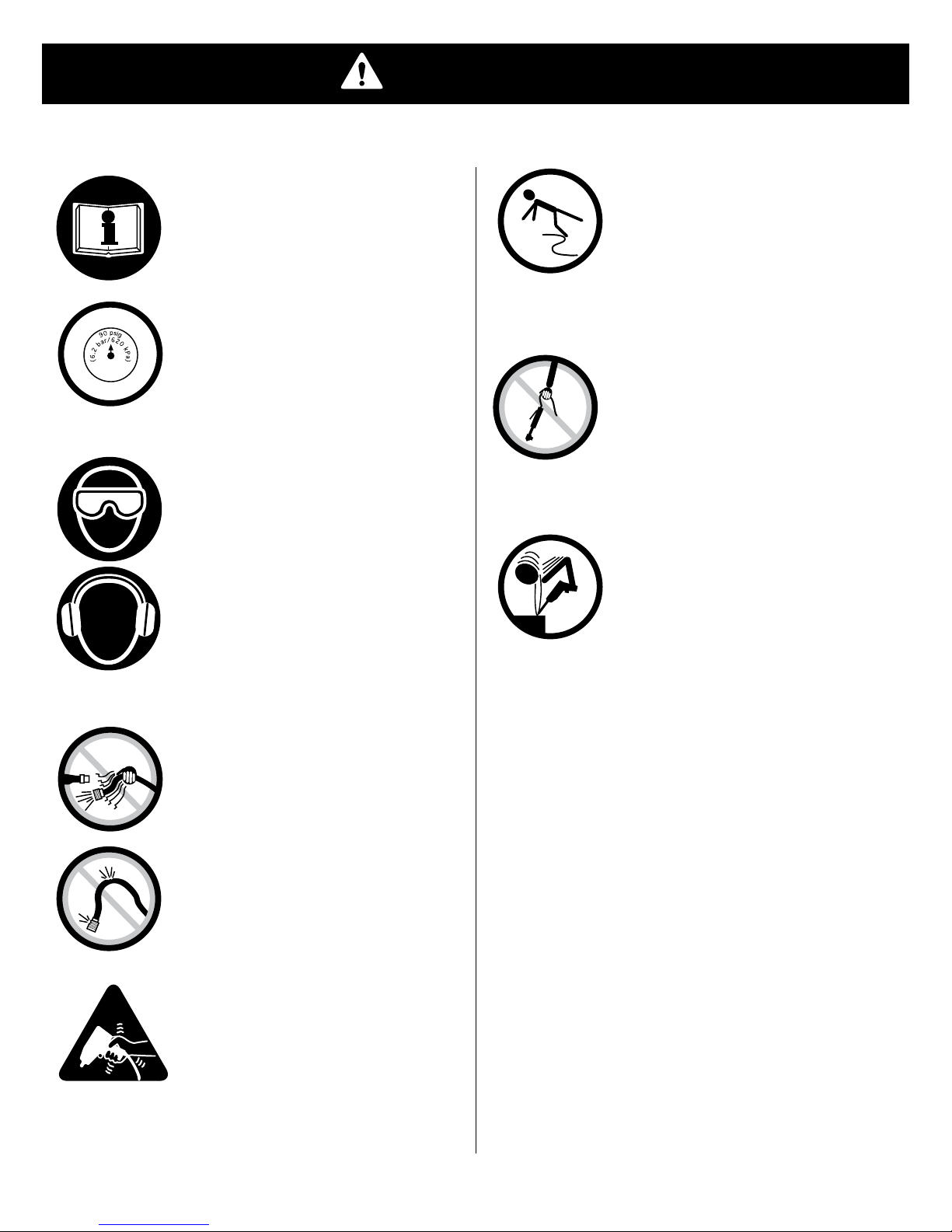

AVOID PROLONGED EXPOSURE TO VIBRATION

RPM OF CUTTING WHEEL MUST MEET OR

EXCEED RPM OF TOOL (20,000 RPM)

WEAR HEARING PROTECTION

ALWAYS WEAR SAFETY GOGGLES

ALWAYS READ INSTRUCTIONS BEFORE

USING POWER TOOLS

Some dust created by power sanding, sawing,

grinding, drilling, and other construction

activities contains chemicals known to cause

cancer, birth defects or other reproductive

harm. Some examples of these chemicals are:

• leadfromlead-basedpaints,

• crystallinesilicafrombricksandcement

and other masonry products, and

• arsenicandchromiumfrom

chemically-treatedlumber.

Your risk from these exposures varies,

depending on how often you do this type

of work. To reduce your exposure to these

chemicals: work in a well ventilated area, and

work with approved safety equipment, such as

those dust masks that are specially designed to

filter out microscopic particles.

RPMRPMRPM

WARNING

WARNING

SX233A: Parts Breakdown & Operating Manual 2 05/12/10

WARNING!

FAILURE TO OBSERVE THESE WARNINGS

COULD RESULT IN INJURY.

WARNING

This Instruction Manual Contains

Important Safety Information.

READ THIS INSTRUCTION MANUAL

CAREFULLY AND UNDERSTAND ALL

INFORMATION BEFORE OPERATING

THIS TOOL.

• Always operate, inspect and maintain this

toolinaccordancewithAmericanNational

StandardsInstituteSafetyCodeofPortable

Air Tools (ANSI B186.1) and any other

applicablesafetycodesandregulations.

• For safety, top performance and maximum

durability of parts, operate this tool at 90

psig/6.2 bar max air pressure with 3/8"

diameterairsupplyhose.

• Always wear impact-resistant eye

protection when operating or performing

maintenanceonthistool.

• Highsoundlevelscancausepermanent

hearingloss.Alwaysusehearingprotection

as recommended by your employer or

OSHAregulation.

• Keep the tool in efficient operating

condition.

• Operators and maintenance personnel

mustbephysicallyabletohandlethebulk,

weightandpowerofthistool.

• Airunderpressurecancausesevereinjury.

Never direct air at yourself or others.

Always turn off the air supply, drain hose

of air pressure and detach tool from air

supply before installing, removing or

adjusting any accessory on this tool, or

beforeperforminganymaintenanceonthis

tool.Failuretodosocouldresultininjury.

Alwayscheckfordamaged,frayedorloose

hoses and fittings, and replace

immediately. Do not use quick detach

couplings at tool. See instructions for

correctset-up.

• Air powered tools can vibrate in use.

Vibration, repetitive motions or

uncomfortable positions over extended

periods of time may be harmful to your

handsandarms.Discontinueuseoftoolif

discomfort, tinglingfeelingorpainoccurs.

Seekmedicaladvicebeforeresuminguse.

• Placethe tool on the work before starting

the tool. Do not point or indulge in any

horseplaywiththistool.

• Slipping, tripping and/or falling while

operating air tools can be a major cause

of serious injury or death. Be aware of

excess hose left on the walking or

worksurface.

• Keep body working stance balanced and

firm. Do not overreach when operating

thetool.

• Anticipateandbealertforsuddenchanges

inmotionduring startup andoperationof

anypowertool.

• Do not carry tool by the hose. Protect the

hosefromsharpobjectsandheat.

• Tool shaft may continue to rotate briefly

after throttle is released. Avoid direct

contact with accessories during and after

use. Gloves will reduce the risk of cuts

orburns.

• Keep away from rotating end of tool.

Do not wear jewelry or loose

clothing. Secure long hair. Scalping can

occur if hair is not kept away from tool

and accessories. Choking can occur if

neckwear is not kept away from tool

andaccessories.

• Correct grinding wheel mounting is

necessary to prevent injury from

broken wheels. Do not use chipped

or cracked grinding wheels. Grinding

wheels should be a free fit on the

spindle to prevent stress at the hole.

Use only wheel collars that come with

the grinder for mounting the grinding

wheel. Flat washers or other adapters

may over stress the wheel. Always use

heavy paper blotter discs between the

wheel collars and the grinding wheel.

Tighten the wheel on the spindle to

prevent spin off when the air grinder

isturnedoff.

• Do not lubricate tools with flammable or

volatile liquids such as kerosene, diesel

orjetfuel.

• Donotforcetoolbeyonditsratedcapacity.

• Do not remove any labels. Replace any

damagedlabels.

• Use accessories recommended by

SunexTools®.

SX233A: Parts Breakdown & Operating Manual 3 05/12/10

SX233A

UTILITY CUT-OFF TOOL

REF.

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

DESCRIPTION

Motor Housing

Lever Pin

Air Inlet

Throttle Lever

Valve Stem

Exhaust Deflector

O-Ring

Valve Spring

O-Ring

Throttle Valve Plug

O-Ring

Rotor Bushing

Ball Bearing

Rear End Plate

Rotor

Rotor Blade

Pin

QTY.

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

4

3

REF.

NO.

18

19

20

21

22

23

24

25

26

27

28

29

*30

31

32

33

34

DESCRIPTION

Cylinder

Front End Plate

Ball Bearing

Air Regulator

Spindle

Retainer

Guard

Hex Screw

Nut

Washer

Spanner

Retainer Ring

Cutting Wheel (pkg. of 5)

Allen Wrench

Spring

Safety Bar

Spring Pin

QTY.

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

PART

NO.

RS380101

RS233A02

RS233A03

RS380104

RS233A05

RS233A06

RS233A07

RS233A08

RS233A09

RS233A10

RS233A11

RS233A12

RS21114

RS233A14

RS233A15

RS233A16

RS233A17

PART

NO.

RS380118

RS233A19

RS10920

RS233A21

RS233A22

RS233A23

RS233A24

RS233A25

RS233A26

RS233A27

RS233A28

RS233A29

87602

RS233A31

RS380132

RS380133

RS380134

*Replacement cutting wheels are sold only in packs of 5.

SX233A: Parts Breakdown & Operating Manual 4 05/12/10

Troubleshooting...

Otherfactorsoutsidethetoolmaycauselossofpowerorerratic

action.Reducedcompressoroutput,excessivedrainontheairline,

moistureorrestrictionsinairpipesortheuseofhoseconnectionsof

impropersizeorpoorconditionsmayreduceairsupply.Gritorgum

depositsinthetoolmaycutpowerandmaybecorrectedbycleaning

theairstrainerandflushingoutthetoolwithgumsolventoiloran

equalmixtureof SAE#10andkerosene.If outsideconditionsare

in order, disconnect tool from hose and take tool to your nearest

authorizedservicecenter.

Operation...

Letthetooldothework.Donotputextremepressureonthe

machine.Thiswillonlyslowdownthespeedofthecuttingwheel,

reducecuttingefficiency,andputanadditionalburdenonthe

motor.Startthetooloffthework,setitdownontheworkevenly

andmoveinthedirectiondesiredtomakethecut.Whenfinished

cutting,liftofftheworkbeforestoppingthemotor.

NOTE:Duringoperation,safetygogglesshouldalwaysbeworn

toguardagainstflyingrustandchips.Useonlywheelsratedat

20,000RPMorhigher.

Air Supply...

Tools of this class operate on a wide range of air pressures. It is

recommendedthatairpressureofthesetoolsmeasures90PSIatthe

toolwhilerunningfree.Higherpressure(over90psig;6.2bar)raises

performancebeyondtheratedcapacityofthetoolwhichwillshorten

toollifebecauseoffasterwearandcouldcauseinjury.

Alwaysuseclean,dryair.Dust,corrosivefumesand/orwaterintheair

linewillcausedamagetothetool.Draintheairtankdaily.Cleanthe

airinletfilterscreenonatleastaweeklyschedule.Therecommended

hookupprocedurecanbeviewedinfigure1.

Lubrication...

Lubricatetheairmotordailywithqualityairtooloil.Ifnoairlineoiler

isused,run1/2ounceofairtooloilthroughthetoolbysquirtingoil

intothetool'sairinletorintothenearestconnectiontothe air inlet,

reconnectingairsupply,andthenrunningtool.Donotusemorethan

1/2ounceofoil,asoverfillingwillreducetheperformanceofthetool.

Operating Instructions • Warning Information • Parts Break down

Shop for other air tools & compressors on our website.

Table of contents

Popular Cutter manuals by other brands

Milwaukee

Milwaukee HEAVY DUTY M12 FCOT Original instructions

SignWarehouse.com

SignWarehouse.com Bobcat BA-60 user manual

Makita

Makita 4112HS instruction manual

GEISMAR STUMEC

GEISMAR STUMEC MTZ 350S manual

Hitachi

Hitachi CM 4SB2 Safety instructions and instruction manual

Dexter Laundry

Dexter Laundry 800ETC1-20030.1 instruction manual