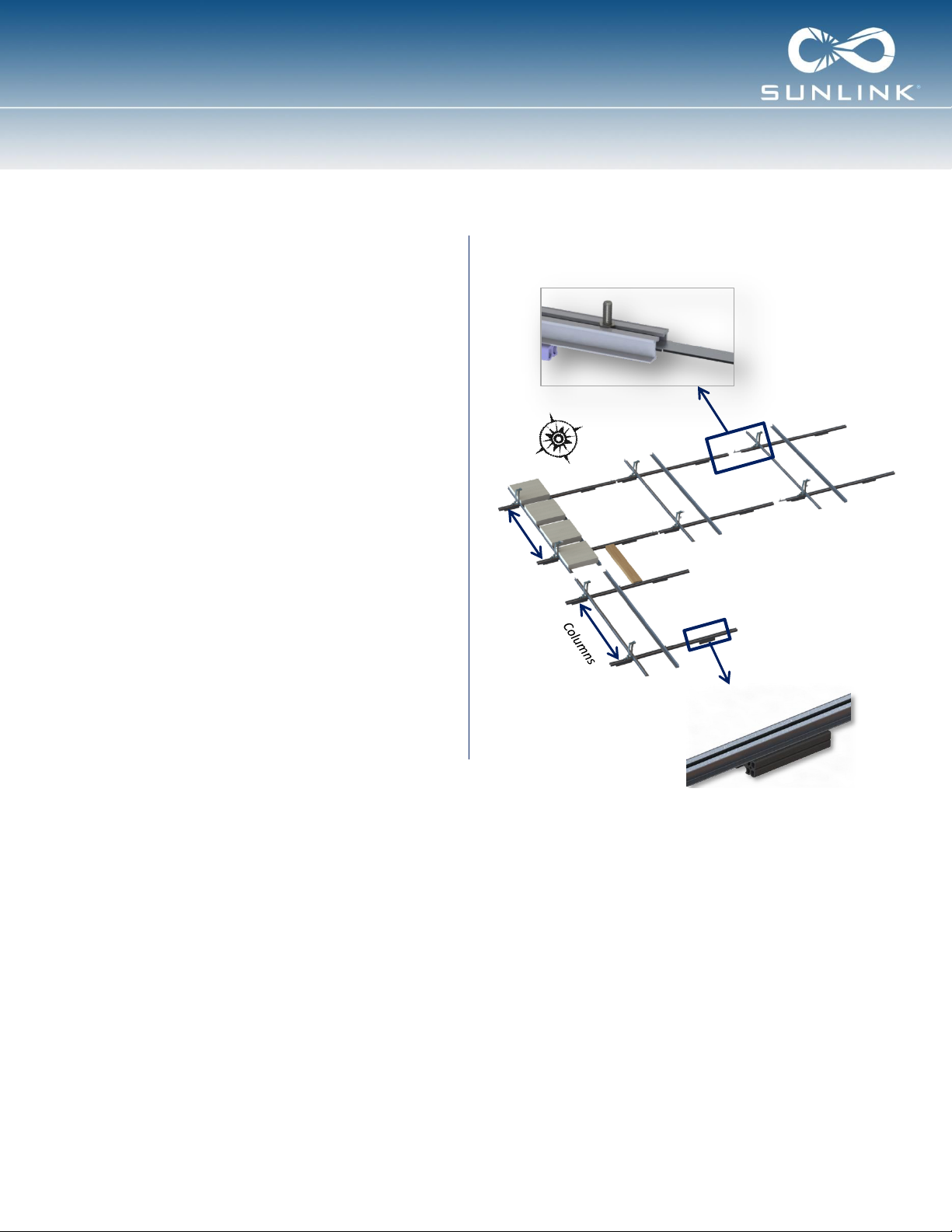

Assembly Instructions for Precision-Modular RMS

REV 02-02-2016 Page 1

Notices and Safety Precautions

Read this document before beginning installation work. Plan for safe practice during any installation activity with respect to

hazards from tripping, falling, lifting, repetitive stress, and any overhead or electrical hazards. When working close to building roof

edges, consider protection options that reduce worker exposure to fall hazards. Refer to OSHA Sub-Chapter 7, Group 1, Article 2.

Precision-Modular RMS is made from aluminum and steel alloys, thermoplastic elastomer, and fastened together with stainless steel

hardware. In the form used in SunLink components, these materials are considered to be non-toxic. Metal components often have

sharp edges. Handle carefully! Wearing gloves is good practice.

This document is not prescriptive regarding safety and does not purport to address all the safety concerns that may arise with its

use. Contractors should become familiar with all applicable safety, health and regulatory requirements before beginning work.

Electrical safety notice –Any time a SunLink system contains two or more electrically interconnected modules, a shock hazard is

present. SunLink is a mechanical system and contains no “live” parts. Mechanical installers and electricians should coordinate in

order to ensure that all personnel are aware of electrical hazards.

Precedence –Precision-Modular RMS positions and secures photovoltaic modules. DC “stringing” and interconnection of the

modules requires placement of conduit, conduit fittings and combiner boxes. Nothing in this document is intended to limit the

allocation of rooftop space or to control crafts with respect to work precedence and coordination.

Build rate –Estimated mechanical installation rate (modules per day) for an array consisting of modules installed with a PRECISION-

MODULAR RMS and assuming a well-equipped four-person crew is on the roof and working 7.5 hours / day with full task

interchangeability: 300 modules / day.

As-built documentation process –On-roof use and mark-up of this document is good practice. Mark up and annotate the drawings

on a regular basis, noting completions, exceptions, dimensional inconsistencies, etc.

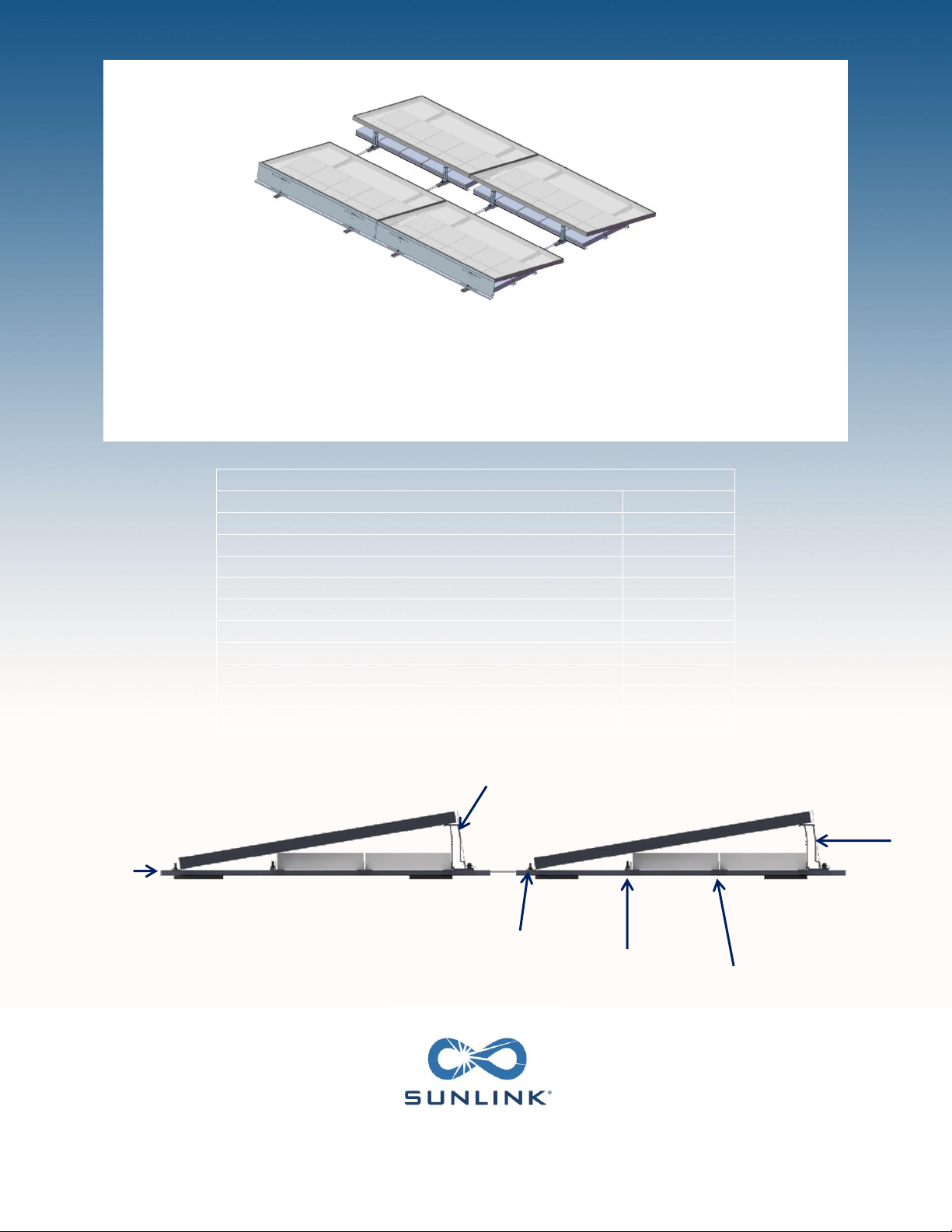

Ballast –Precision-Modular RMS is a ballasted system, meaning that its primary means of retention on the roof is the weight of the

system. The ballast is engineered to work with the environmental and structural constraints of each project, therefore the number

and location of ballast units shown on the engineering documentation needs to be strictly adhered to. Any alterations considered

need to be approved by SunLink.

Field modifications –Unauthorized field modification of SunLink components or assemblies may affect SunLink warranty coverage.

Provide marked up drawings for SunLink’s review, comment and approval prior to attempting any field modifications.

Fire Safe Roof –Precision-Modular RMS is to be mounted over a fire resistant roof covering rated for the application. Precision-

Modular RMS is not meant for sloped roofs where the slope is greater than 1/2 in perft , (2.3° or 7%.)

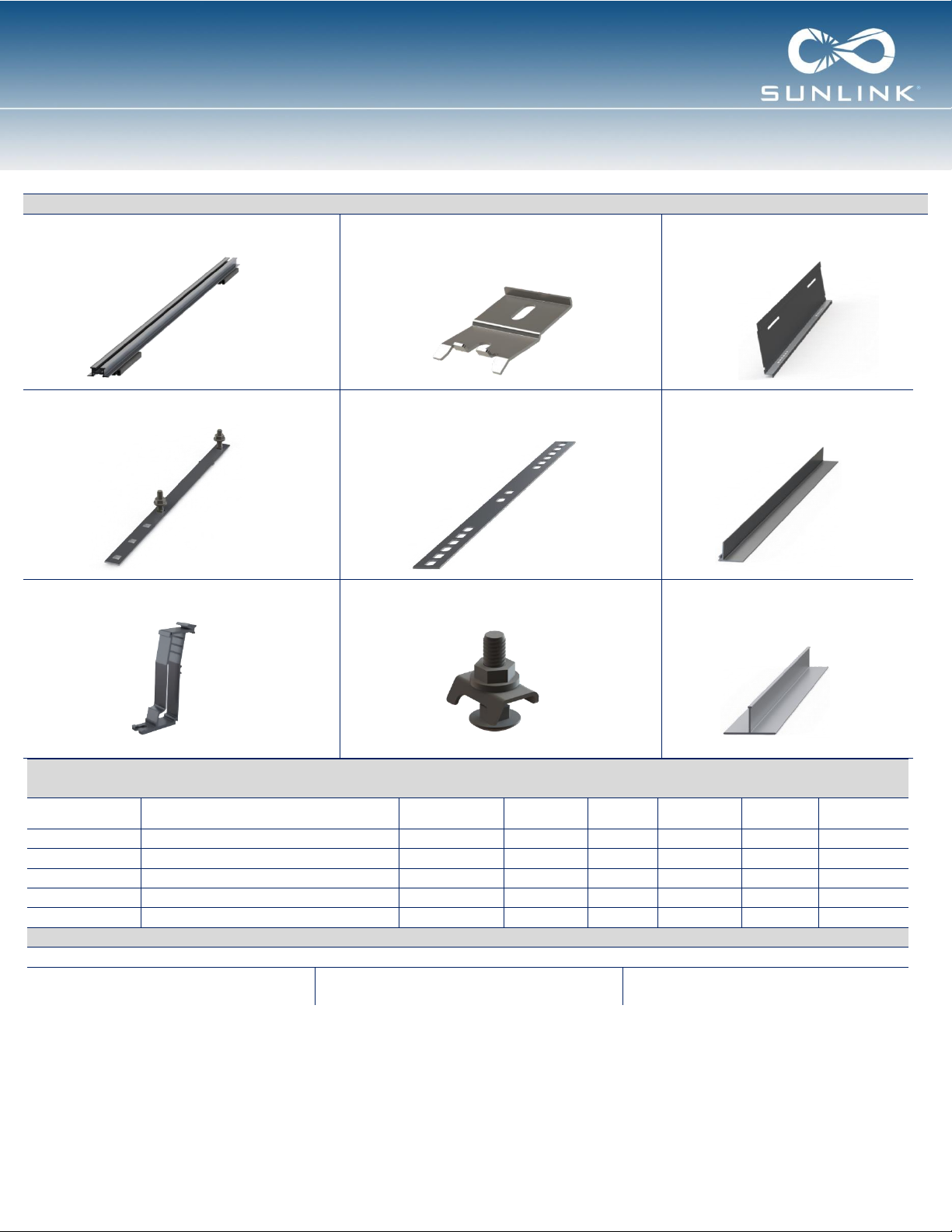

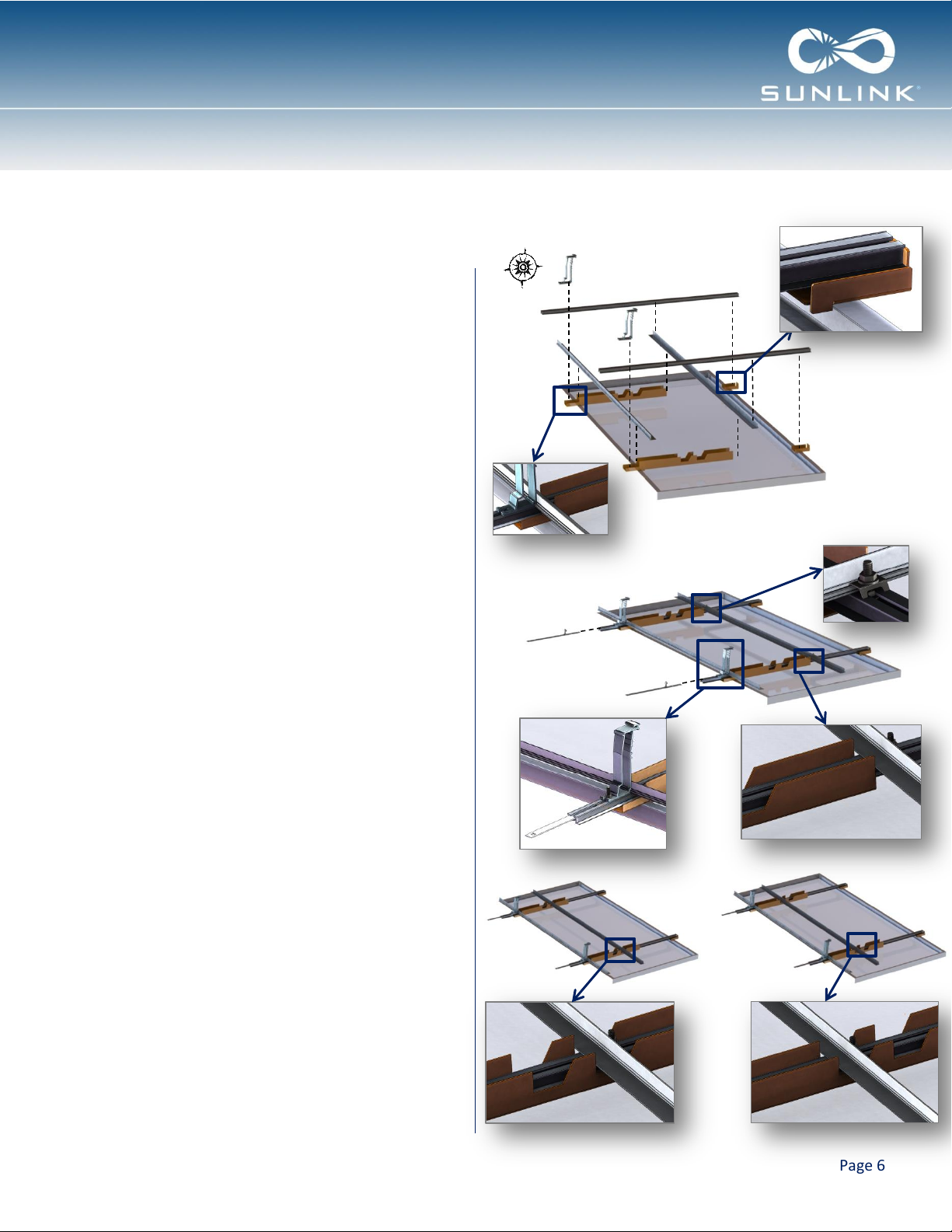

Fit-up –Precision-Modular RMS is a designed-fit system and is assembled using fasteners and assembly bolt sets. Matching hole

locations are engineered to ensure long-term reserve assembly strength and life cycle reliability. Since undulation and slope is

required to ensure roof drainage, SunLink incorporates features that allow the array to follow the roof contour. Some connections

are adjustable and can be modified to change the geometry. In-field changes should be documented and authorized by SunLink.

Roof life and care –The service life of any roof is contingent upon care for the roof especially during equipment installation on a

roof. Avoid concentrated loads on the roof. Never drag SunLink components into place. Instead, elevate the component and then

move it manually or with a cart. Locate it and then place it “on spot.” To ensure roofing system warranty continuation, work with

roofing system installation contractors to ensure roofing system –array compatibility.