No. 7, Road 12, Industrial Zone, Taichung City 407, Taiwan

Tel: 886-4-2359-1190 sales@sunriseiw.com.tw

Fax: 886-4-2359-3409

www.sunriseiw.com.tw

i

TABLE OF CONTENTS

Introduction ……………………………………………….…… 1

Safety Precautions ……………………………………………… 2

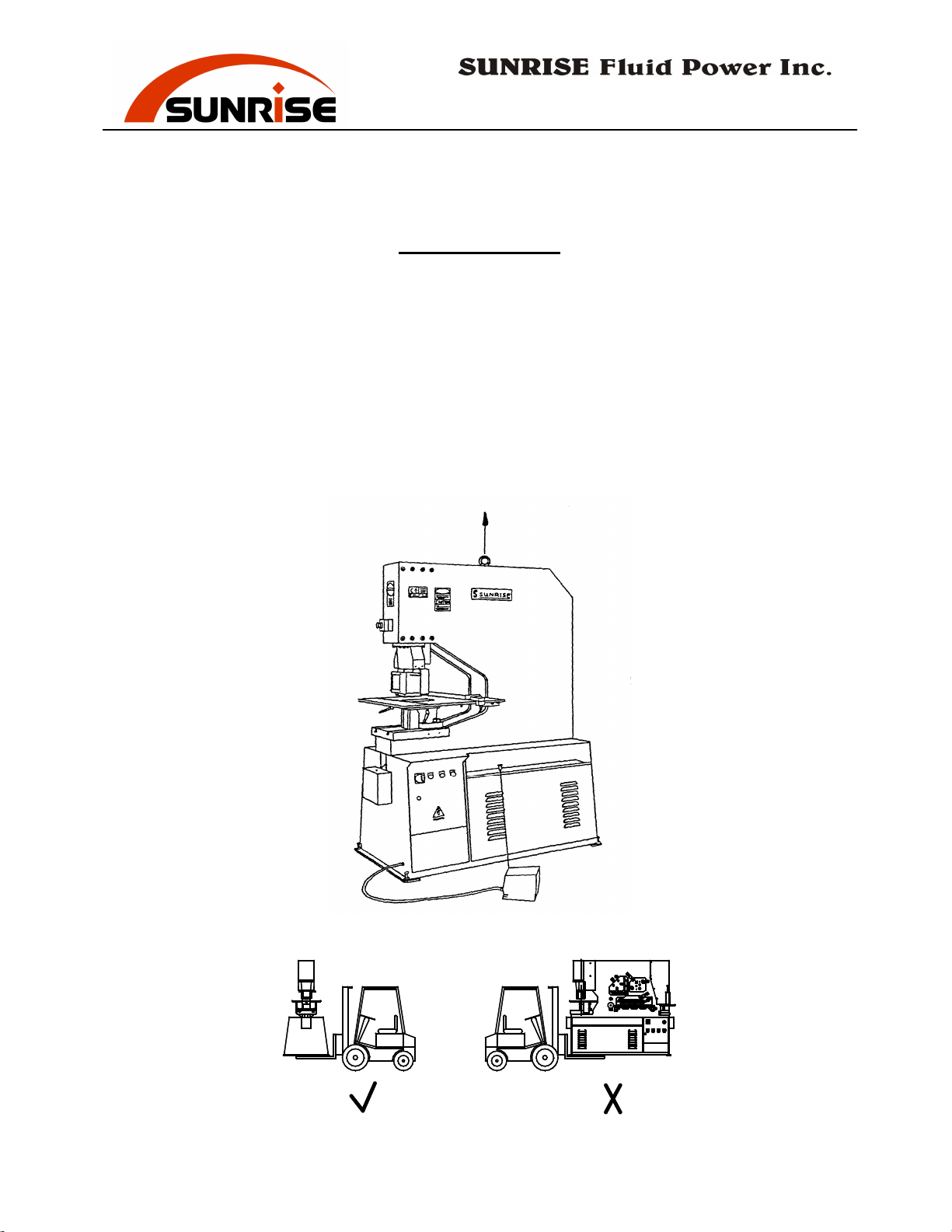

Transport …………………………………………..…………… 6

Installation ………………………………………………………7

Standard Equipment ………………………………..……….… 9

Control Switches………...…………………………………….… 10

Low pressure tool alignment with JOG mode……...………….… 12

Foot Switch …………………………………………………… 13

Stroke Adjustment …………………………………..………… 14

Adjust the Punch Cylinder Ram ……………………………… 15

Punching Station …………………………………….………… 16

Standard Equipment ……………………………………… 16

Alignment of Punch and Die ………………..…………… 16

Punch and Die Clearance ………………..……………… 17

Adjusting Stripper ………………………….…………… 17

Actual Punching Force ………………………..………… 18

Precaution ……………………………………….……… 18

Punch and Die Lubricant ………………………….…… 18

Punch Operation ……………………......…………….… 19

Punching Station Assembly ……………………………. 21

Optional Tooling

I. Press Brake ……………………….…….……..…… 22

II. Duplicating Table …………………..……………… 23

III. Hydraulic Punching Stripper ………….…………… 25

Maintenance …………………………………………………… 26

Trouble Shooting ………………………………..…….……… 28

Hydraulic Circuit Diagram PM-35 ………………..…………… 30

Hydraulic Parts PM-35 ……………………………………….… 31

Hydraulic Circuit Diagram PM-55, PM-80 …………..……….. 32

Hydraulic Parts PM-55, PM-80 ………………………………… 33

Hydraulic Circuit Diagram PM-120, PM-160, PM-200 ……..… 34

Hydraulic Parts PM-120, PM-160, PM-200………………….…. 35

Electrical Circuit Diagram ………………………………….… 36

Electrical Parts List …………………………………………… 37