SUNSTONE Scout User manual

Other SUNSTONE Welding System manuals

SUNSTONE

SUNSTONE PicoDC User manual

SUNSTONE

SUNSTONE Venus GX User manual

SUNSTONE

SUNSTONE CD200DP-A User manual

SUNSTONE

SUNSTONE CDDP-A User manual

SUNSTONE

SUNSTONE Linear DC User manual

SUNSTONE

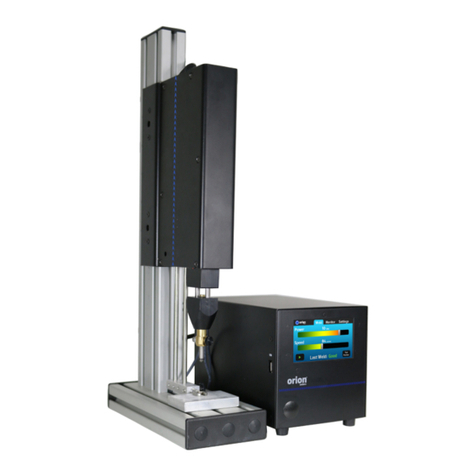

SUNSTONE Orion LZR Benchtop Laser Welder User manual

SUNSTONE

SUNSTONE Orion mPulse User manual

SUNSTONE

SUNSTONE CDSP User manual

SUNSTONE

SUNSTONE Orion 50p User manual

SUNSTONE

SUNSTONE Zapp User manual

SUNSTONE

SUNSTONE Orion M Series User manual

SUNSTONE

SUNSTONE AC 5.0 kVA User manual

SUNSTONE

SUNSTONE Orion c Series User manual

SUNSTONE

SUNSTONE WH1 User manual

SUNSTONE

SUNSTONE Orion 200i User manual

SUNSTONE

SUNSTONE Orion 150s Series User manual

SUNSTONE

SUNSTONE Zapp Plus User manual

SUNSTONE

SUNSTONE MICRO E User manual

SUNSTONE

SUNSTONE Orion i Series User manual

SUNSTONE

SUNSTONE AC1050 User manual

Popular Welding System manuals by other brands

Hobart Welding Products

Hobart Welding Products AirForce 375 owner's manual

GF

GF MSA 330 instruction manual

Hakko Electronics

Hakko Electronics FX-888D instruction manual

Abicor Binzel

Abicor Binzel ABIPLAS WELD 100 W operating instructions

EWM

EWM Taurus 355 Basic TDM operating instructions

Thermal Dynamics

Thermal Dynamics PakMaster 100 XL plus operating manual