4

INSTALLATION and OPERATION MANUAL

INSTALLATION and OPERATION MANUAL

INSTALLATION and OPERATION MANUALINSTALLATION and OPERATION MANUAL

1.1. Requirements to water tank

installation room

Whenchoosingaroomfortankinstallation

observethefollowingrequirements:

- to have a drainage channel. Some

maintenanceproceduresrequiredraining

of all water from the tank.

- Thermal insulation of the room. This

provides efficiency of the appliance and

preventsthewaterfromfreezing.

1.2.Requirementsforinstallaon.

•Thelengthofconnecngpipesbetween

thewatertankandconsumermustbeas

shortaspossible.

• Before connecng the boiler to the

installaon, check all screw connecons

(bolt inspecon cover ange, plug and

anode). In very rare cases - during

transportaon, loading and unloading

operaons- thescrewconneconsmay

beloosen.

• Before commissioning, check the

installaonforleaks.

•Donotexceedtheworkingpressureof

3bar.

•Ifthereisariskoffreezingofwaterin

thetank-drainthetankcompletelyorlet

thewaterheaterworksconnuously.

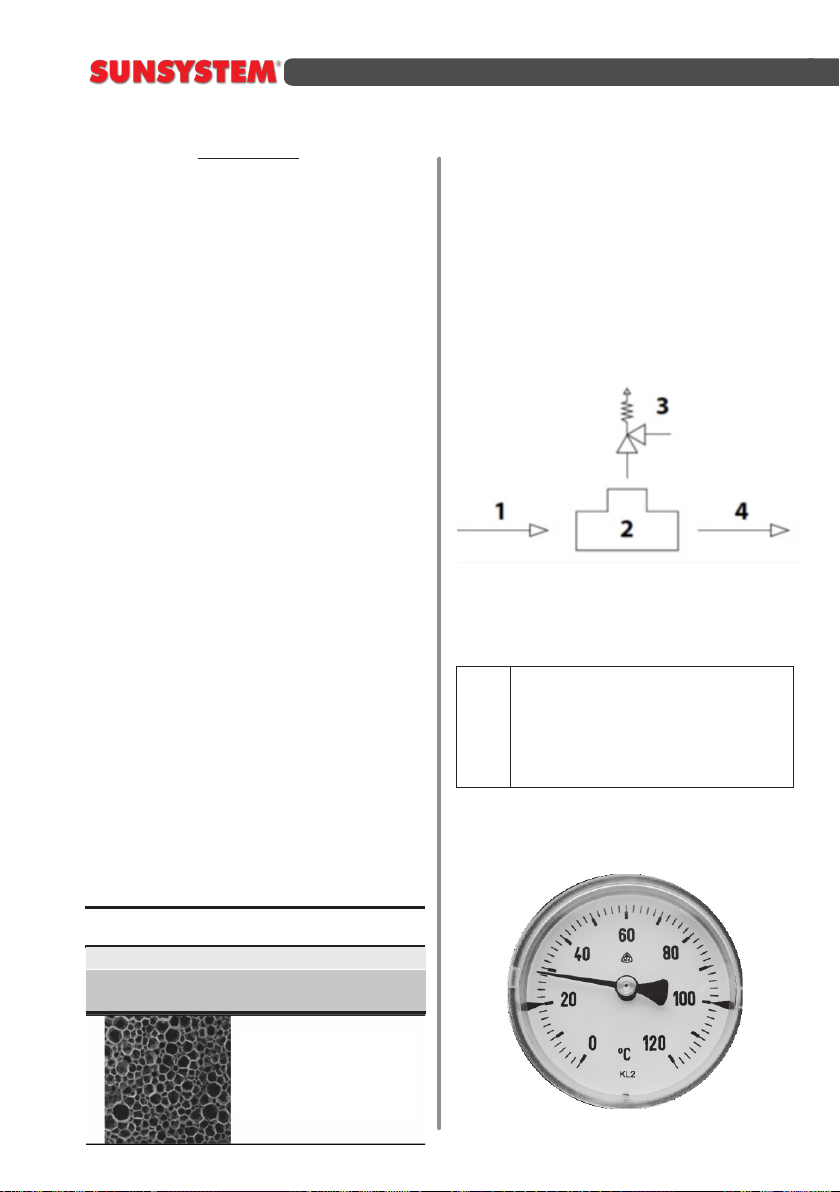

2. DESCRIPTION OF BUFFER TANK

Accumulatestheheatgeneratedbyboiler;

recommended for each space-heang

system. Ensures opmum operang

mode of biomass boiler, perming its

Dear Customers,

This manual contains important

informaon for the safe and correct

installaon, start-up and trouble-free

operaon and maintenance of buer

tank. Observing the instructions of this

Manualisintheinterestofthecustomer,

anditisoneoftheguaranteetermsand

conditions.

1. INSTRUCTION TO INSTALLER

The preparation, installation

and commissioning must be

performed by an authorized

installer / service.

During installation and operation, the

country specific requirements and

regulationsmustbe

observed:

• local construction regulations on

installation of water tank; weight of the

boilertocomplywith

the stability of the floor of the room

whereitwillbeinstalled.

• regulations and norms concerning

the fitting of the installation with safety

devices.

• safety during installation - personal

protectiveequipment

iUse only original SUNSYSTEM

parts.