3

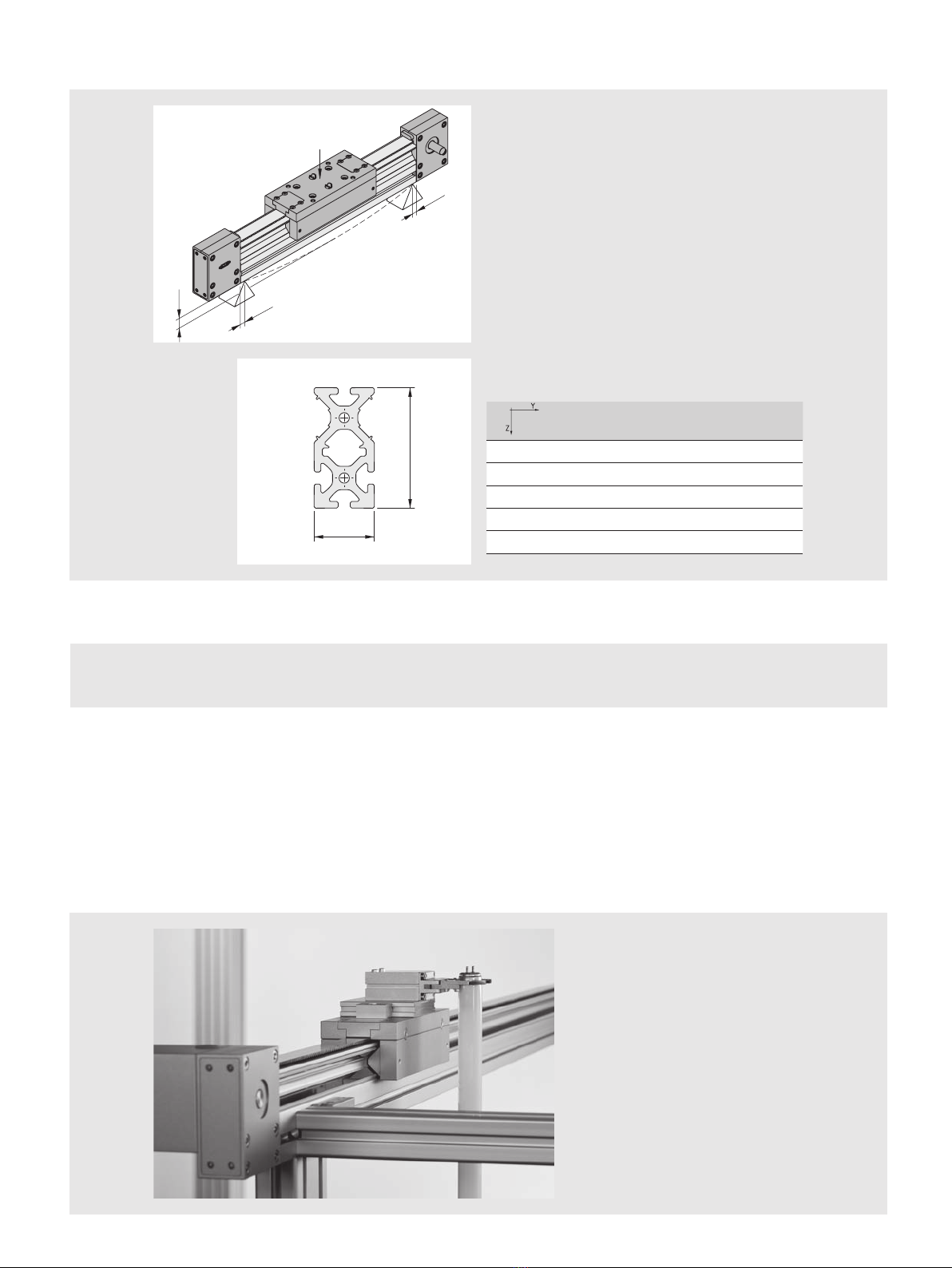

Linear Unit KRF 8 80x40 ZR

Correct use

Improper use

Linear Unit KRF 8 80x40 ZR is a partly completed machine as defined in the

Machinery Directive (2006/42/EC). Linear Unit KRF 8 80x40 ZR must only be

used in accordance with the technical data and safety requirements set out in

this document. Internal company requirements and the regulations that apply

in the country where the product is being used must be observed. You must

not make any design modifications to Linear Unit KRF 8 80x40 ZR yourself. We

will assume no liability for any resulting damage or injury. You may only install,

operate and maintain Linear Unit KRF 8 80x40 ZR if:

Linear Unit KRF 8 80x40 ZR has been integrated properly and safely into the

completed machine,

You have carefully read and understood the installation guide,

You are appropriately qualified,

You are authorised to do so by your company,

You are using only original equipment from the manufacturer.

Unsafe or inappropriate use of Linear Unit KRF 8 80x40 ZR runs a risk of serious

injury through crushing and cuts.

Improper use is defined as any use of the product for purposes other than those

authorised in the installation guide and under the definition of correct use. We

will assume no liability for any resulting damage or injury.

Linear Unit KRF 8 80x40 ZR, as described here, corresponds to the state of

the art and takes into account the general principles of safety applicable at the

time this installation guide was published. Nevertheless, failure to observe the

safety instructions and warning notices in this installation guide may result in

personal injury and damage to property.

We will assume no liability for any resulting damage or injury. We reserve the

right to make technical changes that represent technical advances. Keep these

installation notes in a place where they can be easily accessed by all users.

Observe the directions contained in the main user guide for the completed

machine.

The general safety information applies to the entire lifecycle of the partly

completed machine.

1. During transportation

Observe the handling instructions on the packaging. Until it is installed, the

product must be stored in its original packaging, protected from moisture and

damage. Ensure that moving parts are secured when in transit and cannot

cause any damage.

2. During installation

Always deactivate the power to the relevant system part and ensure it is not live

before installing the product and/or plugging it in or unplugging it. Ensure the

system cannot be switched back on. Lay cables and lines in such a way that

they cannot be damaged and do not represent a trip hazard. Avoid areas that

pose slip, trip and fall hazards.

3. During start-up

Allow the product to acclimatise for a few hours before starting it up. Ensure

that the partly completed machine is securely and safely integrated into the

completed machine. Only start up a product that has been installed in full.

4. During operation

Ensure that only persons who have been authorised by the operator have ac-

cess to the immediate operating environment of the system. This also applies

when the system is not in operation. It must not be possible to actuate moving

parts unintentionally. During emergencies, malfunctions or other irregularities,

deactivate the system and ensure that it cannot be switched back on. Prevent

the possibility of persons becoming trapped in the system’s hazard zone.

5. During cleaning

Close all openings with suitable protective equipment to ensure that cleaning

agents cannot penetrate the system. Do not use aggressive cleaning sub-

stances. Do not use a high-pressure cleaner when cleaning the system.

6. During maintenance and servicing work

Carry out the prescribed maintenance work at the intervals stipulated in the

user guide. Ensure that no line links, connections or components are removed

while the system is live and under pressure. Ensure the system cannot be

switched back on.

7. During disposal

Dispose of the product in accordance with the national and international regula-

tions that apply in your country.