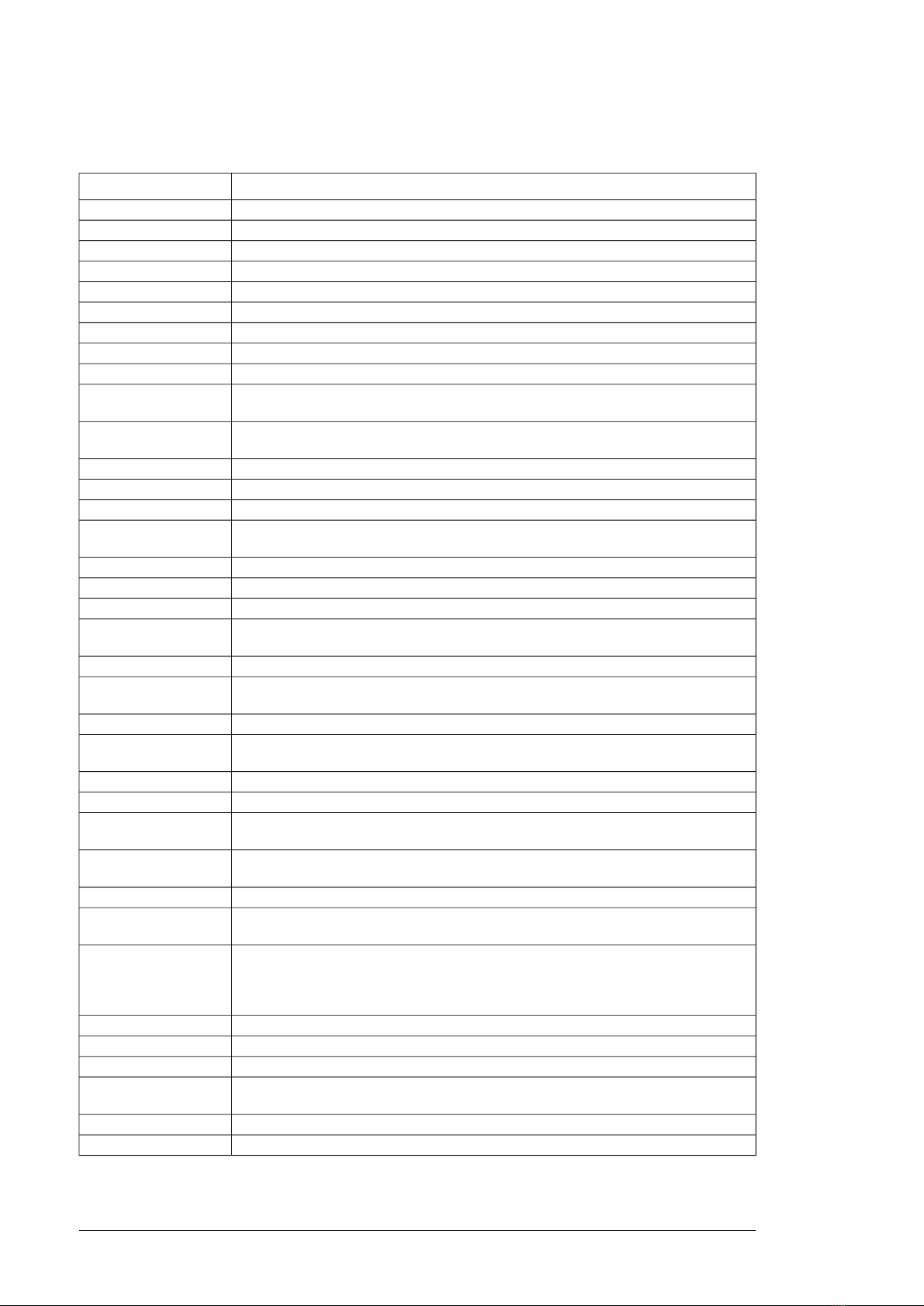

24Power cable types .............................................................................

24Recommended power cable types ......................................................

24Alternate power cable types ..............................................................

25Not allowed power cable types ..........................................................

25Power cable shield ............................................................................

27Selecting the control cables .....................................................................

27Shielding ........................................................................................

27Signals in separate cables ...................................................................

27Signals that can be run in the same cable .................................................

27Relay cable type ...............................................................................

27Control panel to drive connection ...........................................................

28Routing the cables ................................................................................

28General guidelines, IEC ......................................................................

28Continuous motor cable shield or enclosure for equipment on the motor cable .....

29Separate control cable ducts ................................................................

30Implementing thermal overload and short circuit protections ..............................

30Protecting the input power cable against thermal overload .............................

30Diode supply unit ..........................................................................

30IGBT supply unit ...........................................................................

30Protecting the input power cable in short-circuits .........................................

30Diode supply unit ..........................................................................

30IGBT supply unit ...........................................................................

30Protecting the drive against thermal overload .............................................

30Cabinet-installed multidrives .............................................................

30Multidrive modules .........................................................................

31Protecting against short-circuit inside the drive ...........................................

31Cabinet-installed multidrives .............................................................

31Multidrive modules .........................................................................

31Protecting the motor and motor cable in short-circuits ...................................

31Protecting the motor cables against thermal overload ...................................

31Protecting the motor against thermal overload ...........................................

32Implementing a motor temperature sensor connection .....................................

32Connecting motor temperature sensor to the drive via an option module ............

33Connection of motor temperature sensor to the drive via a relay ......................

34Implementing a ground fault protecting function .............................................

34Cabinet-installed multidrives .................................................................

34Residual current device compatibility ...................................................

34Multidrives modules ...........................................................................

34Residual current device compatibility ...................................................

34Implementing the Emergency stop function ..................................................

34Cabinet-installed multidrives .................................................................

35Multidrive modules ............................................................................

35Implementing the Safe torque off function ....................................................

35Implementing the Prevention of unexpected start-up function .............................

35Cabinet-installed multidrives .................................................................

35Multidrive modules ............................................................................

35Implementing the Safely-limited speed function ..............................................

35Cabinet-installed multidrives .................................................................

36Multidrive modules ............................................................................

36Implementing the functions provided by the FSO-xx safety functions module ..........

36Cabinet-installed multidrives .................................................................

36Multidrive modules ............................................................................

6 Table of contents