TERMET TERMAQ Series User manual

TA

1450

012-12

INSTALLATION AND OPERATION MANUAL

Instantaneous gas water heater

DEAR CUSTOMER,

Congratulations on choosing the termet product.

You have purchased a modern, economical and environment-friendly

product that complies with high EU quality standards.

Please take time to get yourself familiarised with this manual, as full

understanding of the product's functions, as well as knowledge of

manufacturer's recommendations is imperative for its smooth,

economical and safe operation.

Please keep this manual handy throughout the whole operational

lifetime of the water heater.

We hope you will be satisfied with our product.

IO-752:2018/EN 05.12.2018

1

CONTENS

1. INTRODUCTION .......................................................................................................................................................2

1.1. IMPORTANT TIPS............................................................................................................................................2

2. PRODUCT DESCRIPTION........................................................................................................................................3

2.1. Technical features.............................................................................................................................................3

2.2. Water heater construction and technical data...................................................................................................3

2.2.1. Main components of the water heater......................................................................................................3

2.2.2. Technical data...........................................................................................................................................5

2.3 Protection equipment ........................................................................................................................................5

3. WATER HEATER INSTALLATION............................................................................................................................5

3.1 Main installation regulations..............................................................................................................................6

3.1.1 Removing and installing the front cover........................................................................................................6

3.1.2 Location.........................................................................................................................................................6

3.1.3 Ventilation......................................................................................................................................................6

3.1.4 Flue gas offtake system ................................................................................................................................6

3.1.5 Gas system ...................................................................................................................................................7

3.2 Preliminary check-up operations.......................................................................................................................7

3.3 Water heater mounting......................................................................................................................................7

3.4 Connecting to the gas supply............................................................................................................................7

3.5 Connecting to the water supply.........................................................................................................................7

3.6 Connecting to a flue system..............................................................................................................................8

4WATER HEATER OPERATION................................................................................................................................8

4.1 Preparing the water heater for the first start-up................................................................................................8

4.2 Water heater starting-up ...................................................................................................................................9

4.3 Water temperature and water flow regulation...................................................................................................9

4.4 Water heater switching off...............................................................................................................................10

5ADAPTATION OF THE water HEATER TO COMBUST OTHER TYPES OF GAS................................................10

5.1 Gas consumption values.................................................................................................................................10

6KEEPING IN THE RIGHT TECHNICAL CONDITION.............................................................................................10

6.1 Heat exchanger cleaning (removing sediment and scale)..............................................................................10

6.2 Burner maintenance........................................................................................................................................11

6.3 Water filter cleaning.........................................................................................................................................11

6.4Gas filter cleaning............................................................................................................................................11

6.5 Safety system checking ..................................................................................................................................11

6.5.1 Checking the protections against flue gas outflow into the room................................................................11

6.5.2 Checking the protection against heat exchanger overheating....................................................................11

7DIAGNOSTICS ........................................................................................................................................................12

7.1 Igniting system diagnostics .............................................................................................................................12

7.2 Igniting system checking.................................................................................................................................12

7.3 Checking the coils of differentia pressure valve..............................................................................................12

8DEFECTS - CAUSES AND METHODS OF REMOVING........................................................................................13

IO-752:2018/EN 05.12.2018

2

1. INTRODUCTION

This instruction manual describes instantaneous gas

water heaters, adapted for installations with one or more

tap (eg. shower, sink etc.).

All drawings, specifications and another information

included in this instruction are based on the up-to-date

data of the product, available at the moment of issuing

this instruction.

The manufacturer reserves the right to make changes

in gas water heater design, without indicating them in

the instruction, as far as the modifications do not have

influence on the operational and technical features of

the product.

Long-term operation of the product and its reliability

most depend on proper installation and use as well as

performing the maintenance in due time and in proper

way.

1.1. IMPORTANT TIPS

Read this before any installation works or use.

•Gas appliances, that are permitted for use and

signed with symbol are safe if they are being

used appropriately and complying with specific rules

of installation and use.

•This installation guide and user’s manual is an

integral part of the water heater unit and as such it

should be kept at hand, and be studied carefully

throughout, as it contains all the necessary

information and precautions that need to be

observed to ensure the safety of installation, usage

and maintenance of this unit. In case of transferring

the appliance to another user, this manual should be

also attached.

•The installation and regulation works must be

performed by an authorised company.

•A room that the unit will be installed in must provide:

-flue conducting, through a pipe connected to an

individual flue with a proper draught,

- efficient supply - exhaust ventilation –in

accordance with this instruction manual and the

local regulations.

Non-observance of this requirements may be

unsafe for a user and may also cause the product

damage (i.e. example water system freezing).

•The unit may be assembled and started up only after

all the other construction and installation works in its

designated room are finished. It is strictly forbidden

to assemble and use the unit in rooms where

construction or other installation works are still under

way.

•Gas and water systems should be equipped with

appropriate filters, which are not included with the

unit.

•The water heater can be operated only by adults.

•Do not perform any repairs or alterations to the water

heater on your own.

•It is strictly forbidden to make any modifications that

could reduce the clearance of air-intake holes

(covering, blanking off etc.) or uptake and flue ducts

in a room and in the appliance.

•Do not keep any containers with inflammable,

aggressive or strongly corrosive chemicals close to

the water heater.

•It is forbidden to keep or dry clothes or other

inflammable objects on or nearby the appliance and

flue ducts.

•The service and maintenance operations of the

water heater can be only performed by an authorised

company.

•Effects of not - observance the instructions included

in this document by gas engineers or users are

excluded from the warranty coverage.

•After exploitation of the boiler, disassembled product

transfer to a specialized unit for utilization.

The manufacturer will not be liable for any

damage or malfunction of the product caused

by faulty installation or use, as the results of

non-observance the manufacturer instructions

and any relevant, official regulations.

Before you start up the water heater,

concerning for your safety, make sure if:

1. Permanent air supply that is necessary for

gas combustion is provided,

2. The appliance has been connected to an

individual and efficient chimney duct,

3. The gravitational ventilation duct is not

choked.

If you smell a gas:

1. Do not use electric switches likely to

cause a spark.

2. Open the door and windows.

3. Shut down the main gas valve.

4. Contact the gas emergency service.

5. If the gas escapes from an untaught valve

of a gas cylinder, shut down the valve,

disconnect the cylinder and take it outside

the building.

6. If the gas escaping from a leaky valve on

the cylinder catches fire, throw a wet

blanket on the cylinder in order to

extinguish the fire, and then pour water on

it in order to cooling down the cylinder and

make possible to turn off the valve.

In a case of breakdown:

1. Turn off the gas supplying valve.

2. Turn off the water supply if there is a risk

of flooding.

3. If there is a risk of water heater freezing,

drain out the water from it.

If you smell fumes:

1. Switch off the heater by turning off the hot

water tap or shut down the gas valve of

water heater.

2. Open the door and windows.

3. After airing the room, switch on the heater

for a while and check if the gas smell

disappeared. If not, contact the fitter or the

chimney service in order to check the

exhaust system efficiency.

IO-752:2018/EN 05.12.2018

3

2. PRODUCT DESCRIPTION

2.1.Technical features

•Electronic ignition with a ionisation flame control

•Lack of chimney draught protection and fumes

leak protection.

•Heat exchanger overheating protection.

•Proportional power regulation.

•Device adapted for water supply system from 20 to

1000 kPa (0,2 to 10,0 bar)

Gas instantaneous water heaters type GE-19-02 and

GH-19-02 are manufactured as B11BS installation type

version, what means that they are intended to be

connected to the individual flue chimney. Combustion

products are taking out of the room by means of natural

draught. The air for the combustion process is being

taken directly from the room where the water heaters

are installed. Water heaters are equipped with a

protection against draught loss in a flue pipe and

protection against fumes escape into a room.

The water heaters GE-19-02 and GH-19-02 are

equipped with the most recent technical solutions which

provide long-lasting, faultless and economic

performance and the comfort of use.

The fittings used in the water heaters ensure

proportional power regulation, which enables to get

constant temperature of outflowing water.

Activation (burner ignition) of the water heater takes

place with each opening of the tap. Shutdown takes

place after closing the tap.

One of the main advantages of the water heaters is little

water flow necessary to start up the appliance (about

3,2 l/min).

Each water heater is destined to combust only one type

of gas (for example 3B-G30) and the water heater must

be fed only with this type of gas.

The water heater’s type, the group and type of gas, as

well as the service line pressure which the water heater

was designed for, are marked on the packaging, in the

instruction manual and on the marking plate.

The water heater can be converted to another type of

gas only by an Authorized Service Center in accordance

with point 5.

2.2. Water heater construction and

technical data

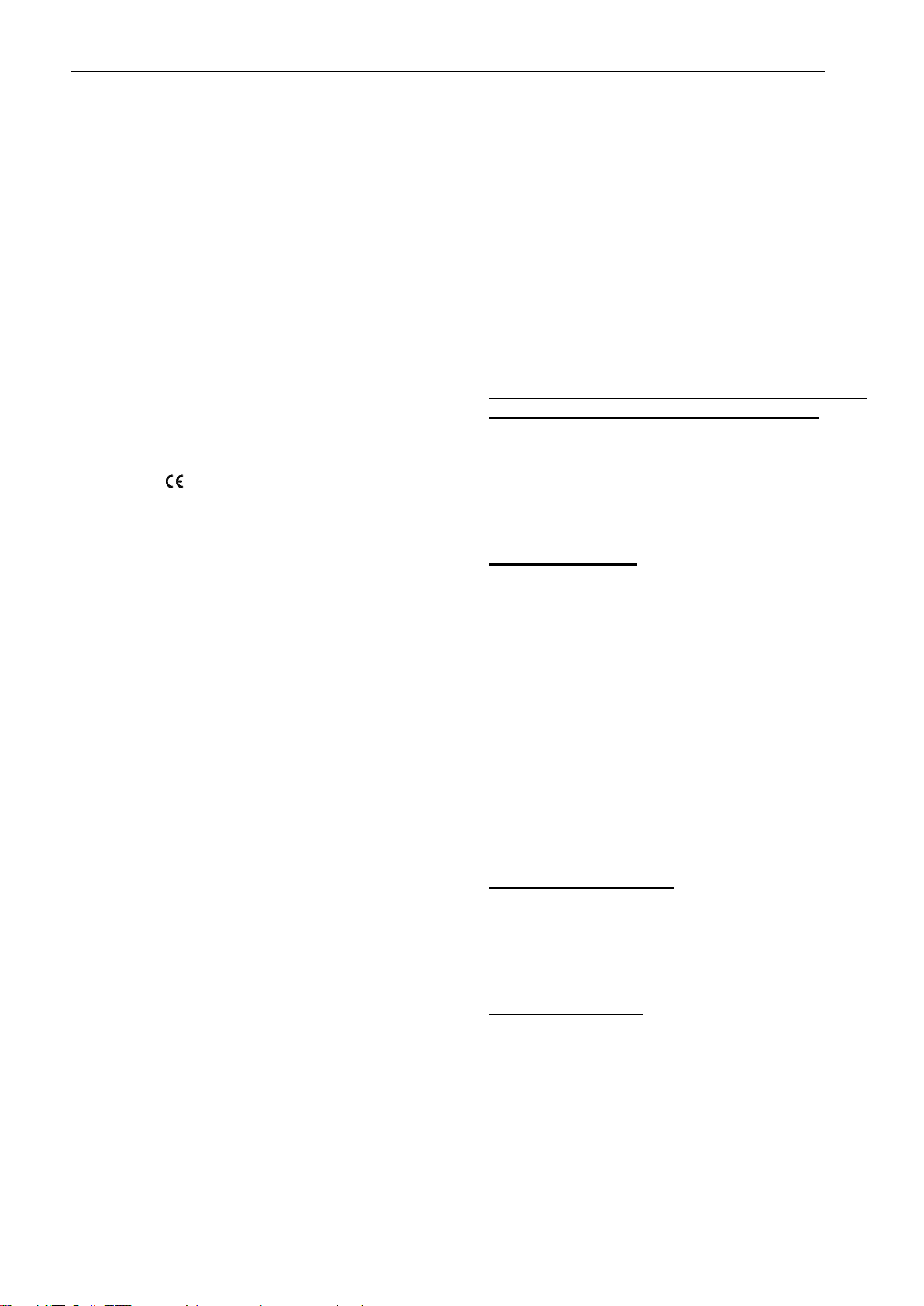

2.2.1. Main components

of the water heater

Temperature limiter as protection against overheating

of the heat exchanger

Fig. 2.2.1.1 Main components of the water heater

1 Burner

2 Electrode set

3 Water-gas fittings

4 Heat exchanger

5 Draught breaker

6 Spark generator

7 Battery compartment

8 Temperature limiter - protection against flue gas

outflow into the room

6 7

8

5

4

2

1

3

7

IO-752:2018/EN 05.12.2018

4

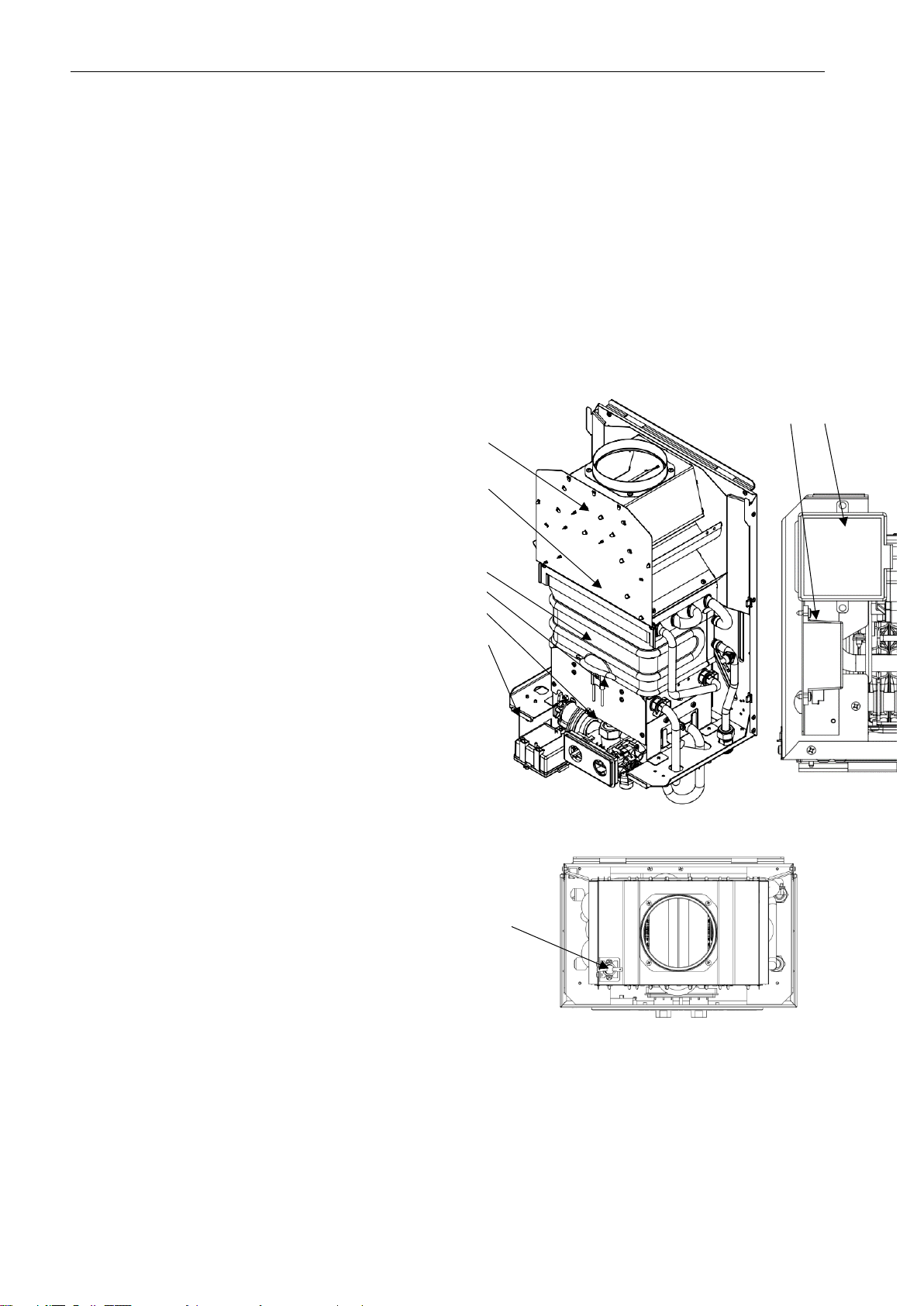

Fig. 2.2.1.2 Schematic diagram of the water heaters

1. Burner

2. Electrode set

2.1. Igniting electrode

2.2. Ionisation electrode

3. Water-gas fittings

3.1. Gas flow knob

3.2. Temperature selection knob

3.3. Gas filter

3.4. Water supply filter

3.5. Differential pressure valve

3.5.1.Coil I of the differential pressure valve

3.5.2.Coil II of the differential pressure valve

3.6. Regulating screw of the microswitch

3.7. Regulating screw of the little water flow

3.8. Microswitch

4. Heat exchanger

5. Spark generator

6. Battery compartment

7. Hydrogenerator

8. Temperature limiter - protection against flue gas

outflow into the room

9. Temperature limiter - protection against

the heat exchanger overheating

10. LED display

11. Cable assembly

IO-752:2018/EN 05.12.2018

5

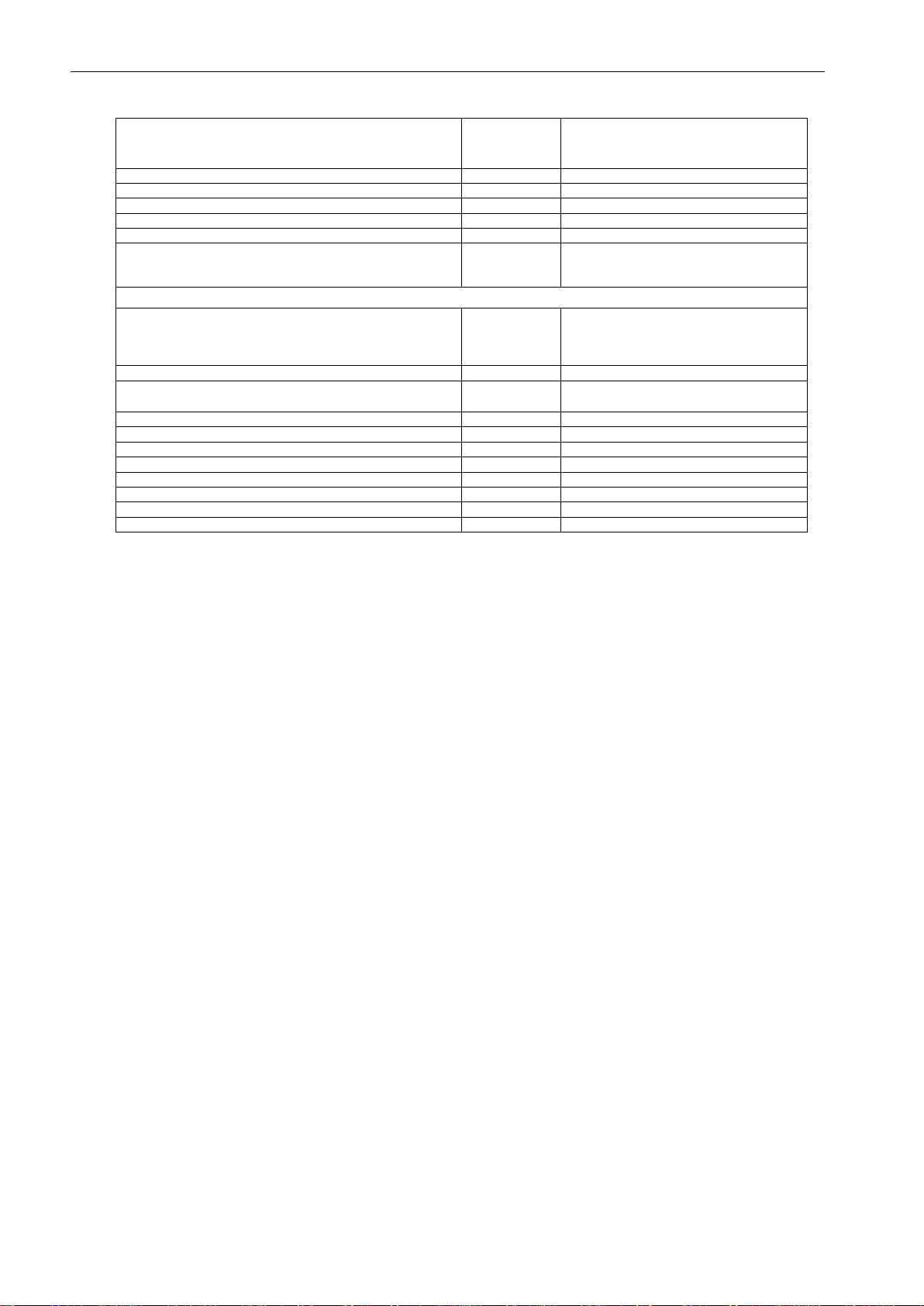

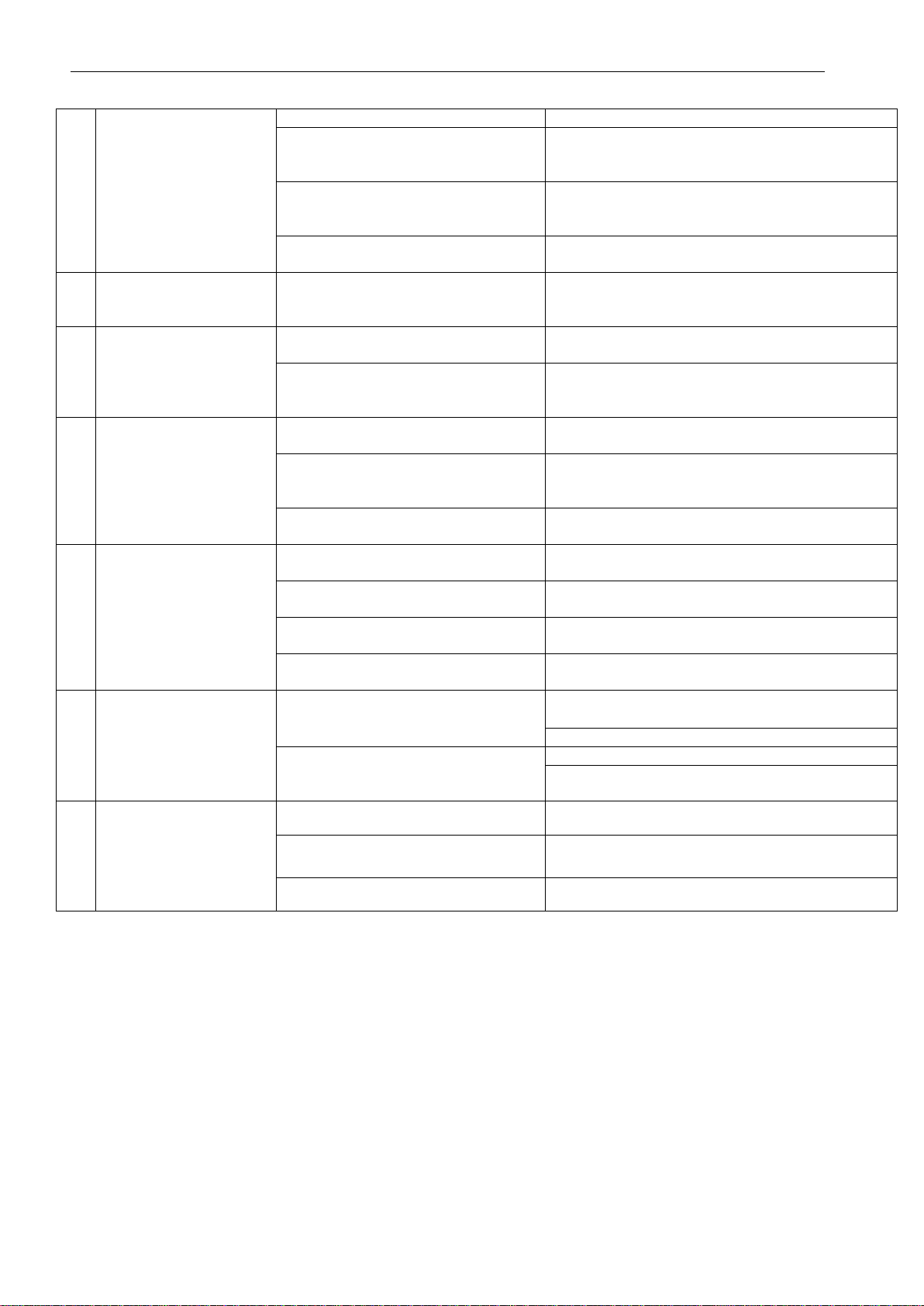

2.2.2. Technical data

2.3 Protection equipment

•Protection against flue gas outflow into the room (case of draught loss) consists of a temperature limiter (item

8) connected in series with electric supply. This protection unit shuts down the main gas valve in the water - gas

fittings and cutting off the gas supply to the burner if the draught of the chimney duct is below 3 Pa or overpressure

occurs.

After the protection switches off the water heater, it is necessary to turn off a water tap. After about 10 minutes

(after cooling down the temperature limiter; this time depends, among others, on the room temperature), the

protection is automatically unlocked. After turning on a water tap there will flow hot water.

If activation of this protection device repeats, it is necessary to contact proper chimney sweep service

company in order to check-up the draught of a flue system.

Protection against a lack of chimney system draught must not be switched off.

The user must not make any modifications on the protection equipment.

Switching off or damaging the protection system may cause the leakage in a flue system.

•Anti-outflow protection –basing on ionization flame control - causes cutting off the gas supply to the burner by

means of electric system - in the case of flame disappearance.

•Protection against the heat exchanger overheating, i.e. the temperature limiter (item 9) actuates if the water

temperature in the heat exchanger exceeds 950C, by cutting off the voltage in the supply system, and also closing

the gas supply to the burner.

It is forbidden to make any modifications in the water heater protection systems.

3. WATER HEATER INSTALLATION

After all installation works are completed, it is necessary to check up if all gas and water connection are tight.

Diagram of the water, gas and flue –gas discharge system is presented on the Fig. 3.1.3.1

NOTE:

The wires, water and gas connection elements (filters, valves), neither flue –gas discharge elements are not included

in water heater equipment.

Parameter

Unit

GE-19-02

GH-19-02

Nominal input power

kW

19,2

Minimal input power

kW

7,7

Nominal heat load

kW

21,8

Minimal heat load

kW

8,8

Efficiency

%

88

Nominal gas consumption1) of a main burner, for:

Natural gas: 2H-G20

Liquefied gas: 3+-G30/G31-28÷30/37mbar

m3/h

kg/h

2,3

1,7

1) Consumption of particular types of gas is given for reference gases, in reference conditions: (150C, pressure1013 mbar) allowing for 87% of water heater efficiency

Rated gas kinetic pressure on the water heater connection

with a gas supply, for:

Natural gas: 2H-G20

Liquefied gas: 3+-G30/G31-28÷30/37mbar

kPa(mbar)

2,0 (20)

3,7 (37)

Water operating pressure

kPa(bar)

20÷1000 (0,2÷10,0)

Hot water outflow (t500C)

Hot water outflow (t250C)

dm3/min

dm3/min

3,2÷5,7

5,7÷11,5

Maximal temperature of outflow water

0C

65

Flue connection (external diameter)

mm

ø114

Overall dimensions: height / width / depth

mm

590/360/230

Hater weight

kg

9,5

Installation dimensions

mm

fig. 3.6.1

Gas connection

Inch

G 1/2

Cold water connection

Inch

G 1/2

Hot waterconnection

Inch

G 1/2

IO-752:2018/EN 05.12.2018

6

3.1 Main installation regulations

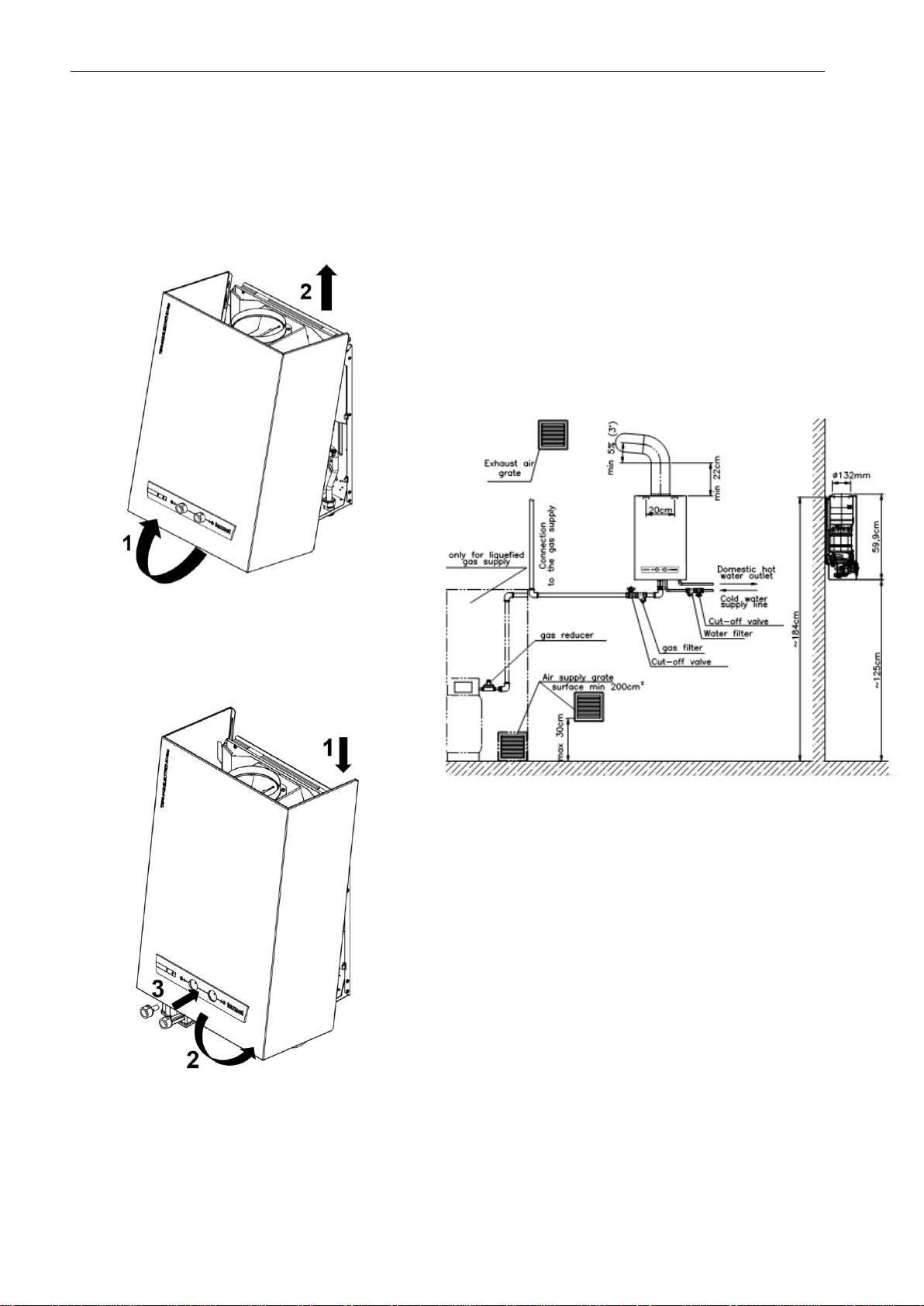

3.1.1 Removing and installing the

front cover

Removing the front cover:

1. Grab the bottom of the cover and pull it towards

you.

2. Lift the cover upwards.

3. Remove the knobs.

Installing the front cover:

1. Put the front cover on the hooks of the back

cover.

2. Place the cover so that the openings of the

panel and fittings are in the same position.

3. Mount the knobs.

3.1.2 Location

•Water heaters cannot be installed in rooms where

people stay most of the time.

•The room cubature –no less than 8 m3.

•The room height–no less than 2.2 m.

3.1.3 Ventilation

•Supply ventilation

In the room where the water heater is installed, there

should be a non-closing hole of supply ventilation, of

the surface not less than 200 cm2, whose lower edge

should be not higher than 30 cm above the floor level.

It is admissible to supply the outside air from the

adjacent rooms equipped with a non-closing hole of

supply ventilation of the surface not less than 200 cm2.

•Exhaust ventilation

In the room where the water heater is installed, there

should be a non-closing hole of exhaust ventilation

with the surface not smaller than 200 cm2, placed as

close to the ceiling as possible.

It is not allowed to use mechanical exhaust

ventilation (e.g. kitchen ventilating hood).

3.1.4 Flue gas offtake system

Water heater should be installed as close as possible to

the individual chimney duct and in a place not exposed

to frost. The cross-sections of the pipe as well as the

flue duct should remain the same along the entire length.

The flue duct should leave the appliance vertically (min.

220mm) to the first elbow. The horizontal section of the

flue duct at the lift of 5% (ca. 3o), should not exceed the

length of 2m (Fig. 3.1.3.1) The length of the flue duct,

measured from the axis of the flue duct inlet to the edge

of the duct outlet above the roof should not be less than

2m. The internal surface of the flue-gas duct should be

corrosion-resistant.

•Water heater connection to the flue gas duct must be

agreed with the proper chimney sweep company and

should meet the requirements presented on Fig.

3.1.3.1.

For the correct water heater operation, the flue gas

conducting system must provide the draught not

Fig. 3.1.3.1 Diagram of water, gas and flue –gas

conducting systems

IO-752:2018/EN 05.12.2018

7

less than 3 Pa (0.03 mbar) and not more than 15 Pa

(0.15mbar).

3.1.5 Gas system

Gas appliances should be permanently connected to

steel or copper pipes of the gas system or by means of

metal tubes.

Liquefied gas system

•Gas appliances fed with liquefied gas cannot be

installed in rooms where the floor level is situated

under the ground level.

•The cylinders should be situated in a distance not less

than 1.5 m from heat radiating surfaces (radiators,

stoves, etc.).

•The cylinders cannot be exposed to radiation of

places with open fire.

•The cylinders should be situated in vertical position,

protected against falls, beats, from children etc.

•The cylinders should be placed in a distance of at

least 1 m from devices likely to cause electric

sparkling, e.g. electricity meters.

•The room temperature where the cylinder will be

located cannot exceed +35oC.

Recommendation:

Because the one gas cylinder with the capacity of 11 kg

in the exploitation of the water heater is sufficient for a

short time, it is recommended to use a set of 11-kg

cylinders, so called battery, or a bigger cylinder with the

capacity above 11kg. Such a battery or (max. 10

cylinders) or a larger cylinder should be placed outside

the building.

3.2 Preliminary check-up

operations

Before installation, it is necessary to check if:

•the purchased water heater is adapted for combustion

the type of gas supplied from the gas mains which the

appliance will be connected to. The type of gas the

water heater has been adapted for is designated on

the packaging and the marking plate placed on the

front cover.

•the water system has been rinsed thoroughly with

water, in order to get rid of possible rust, scale, sand

or other foreign matter, which could disturb the proper

operation of the water heater (e.g. increase the

resistance of water flow in the system).

3.3 Water heater mounting

Water heater should be installed in a place not posing

significant difficulties for a service team, on a wall made

of non-flammable materials or isolated from an

inflammable wall with a plate made of non-flammable

material.

In case of building the water heater over in a furniture

system, air supply necessary for proper gas combustion

should be provided (Illus. 3.3.1).

Do not mount the water heater in the neighborhood of

appliances likely to disturb its operating (e.g. over a

cooker from which vapors rise).

Mount the water heater on the wall, on hooks

permanently fixed in it, using two rectangular notches

on the water heater back cover.

Fig. 3.3.1 Required mounting distances

3.4 Connecting to the gas supply

Fig.3.6.1 shows the connection diameters. For gas pipe,

the diameter is G3/4.

Gas water heaters not equipped with gas flow stabilizer

are adopted to be installed in the gas system equipped

with individual mean pressure reducer. Cables with a

valid certificate should be used for installation.

On the system pipe should be installed a cut off

valve and a gas filter. Installing the gas filter is

necessary for correct and long-lasting operation of

the gas unit and the burner. Filter is not included in

the installation kit.

3.5 Connecting to the water supply

Fig.3.6.1 shows the connection diameters. For water

pipe, the diameter is G1/2. On the system pipe should

be installed a cut-off valve.

Connecting the water heater to the water supply system

should be performed by means of flexible connectors or

stiff pipes. These pipes are not included in the

installation kit.

The connection to the water system should be made in

such a way that the geometry of the water heater is

maintained. Incorrect execution of the connection may

cause distortion of the water heater, which may make it

impossible to mount the knobs or lead to their blocking.

In order to stop mechanical pollution, and thus,

provide the water heater reliability and its long-term

operation, a water filter should be installed on the

supplying pipe. The filter must not cause any

resistance for a water flow and should be easy

cleaning. The filter is not included in the basic water

heater equipment.

IO-752:2018/EN 05.12.2018

8

3.6 Connecting to a flue system

Flue gases should be taken off from the water heater to an individual chimney duct, by means of a pipe with external

diameter 117 mm (GE-19-02, GH-19-02), made of the material protected against corrosion.

External diameter 117 mm

Fig. 3.6.1. Installation dimensions (mm)

4 WATER HEATER OPERATION

4.1 Preparing the water heater for

the first start-up

Before proceeding with the first start-up of the water

heater, it is necessary to:

•Fill the water system with water so as after turning on the

water taps water may flow. This ensures that the water

heater will be correctly filled with the water and it will be

operating properly.

•Put on the gas flow knobs and the temperature selection

knobs –push in the knobs drawing attention on their

position in relation to the inside knobs.

•In water heaters GE-19-02

,

open the batterie compartment and insert a R20 batteries

drawing attention to its polarity. Next, close down the

compartment.

IO-752:2018/EN 05.12.2018

9

Fig. 4.1.1 Opening batterie compartment.

Batteries are not included in water heater equipment.

The producer recommends using batteries designed for

RTV equipment.

Do not regenerate the discharged batteries in any way,

do not heat them, do not throw them into a fire –risk of

explosion.

Water heaters are ready to use after installation.

4.2 Water heater starting-up

In order to start-up the water heater it is necessary to:

•Turn on the gas knob on the water heater connection

(for liquefied gas: to open the valve on the cylinder),

•Turn the gas flow knob from the “0” position into one

of the 4 positions of the thermal power of boiler

(stepwise movement of the knob). After turning on

the domestic hot water tap, electric sparkling on the

igniting burner will be heard (6 sec.). After a while

the gas will be ignited on the igniting burner and then

on the main burner.

If the knob is placed in “0” position – spark

generator produces a spark during 70 seconds, gas

on the igniting burner and main burner will not be

ignited.

During the first start-up, the system and the gas

fittings should be vented. Because of this, the first

start-up may last longer than 20 seconds.

Water heater is ready to operate.

After opening the hot water tap, automatic gas ignition

takes place on the burner segment, and at the rest of

segments - after a while hot water will flow out.

After turning off the hot water tap, the gas supply to the

burner will be cut off.

4.3 Water temperature and water

flow regulation

Water heaters are equipped with modern gas-water

fittings ensuring proportional power regulation, what

enables to receive constant water temperature. The

fittings are equipped with a water flow limiter with a

smooth regulation. If the water temperature selection

knob (Illus. 4.3.1) is turned in its extreme right position,

little water flow will be received (i.e. 5,7 dm3/min) with

the highest temperature (gas flow knob in its extreme

left position), smaller flow will be received by decreasing

the flow by means of water tap.

If the temperature selection knob is turned into its

extreme left position, a big water flow will be received

(i.e. 11,5 dm3/min) with the lowest temperature (gas flow

knob position as above).

After setting the temperature selection knob in its

transitional positions, water temperature growths will

change inversely proportional to the water flow.

Decreasing the water flow in the water heater, by means

of the temperature selection knob, from the 11.5 to 5.7

dm3/min, water temperature growth changes from 25º to

50ºC. Water temperature (in any operation positions of

the water flow regulator) can be regulated by means of

gas flow knob

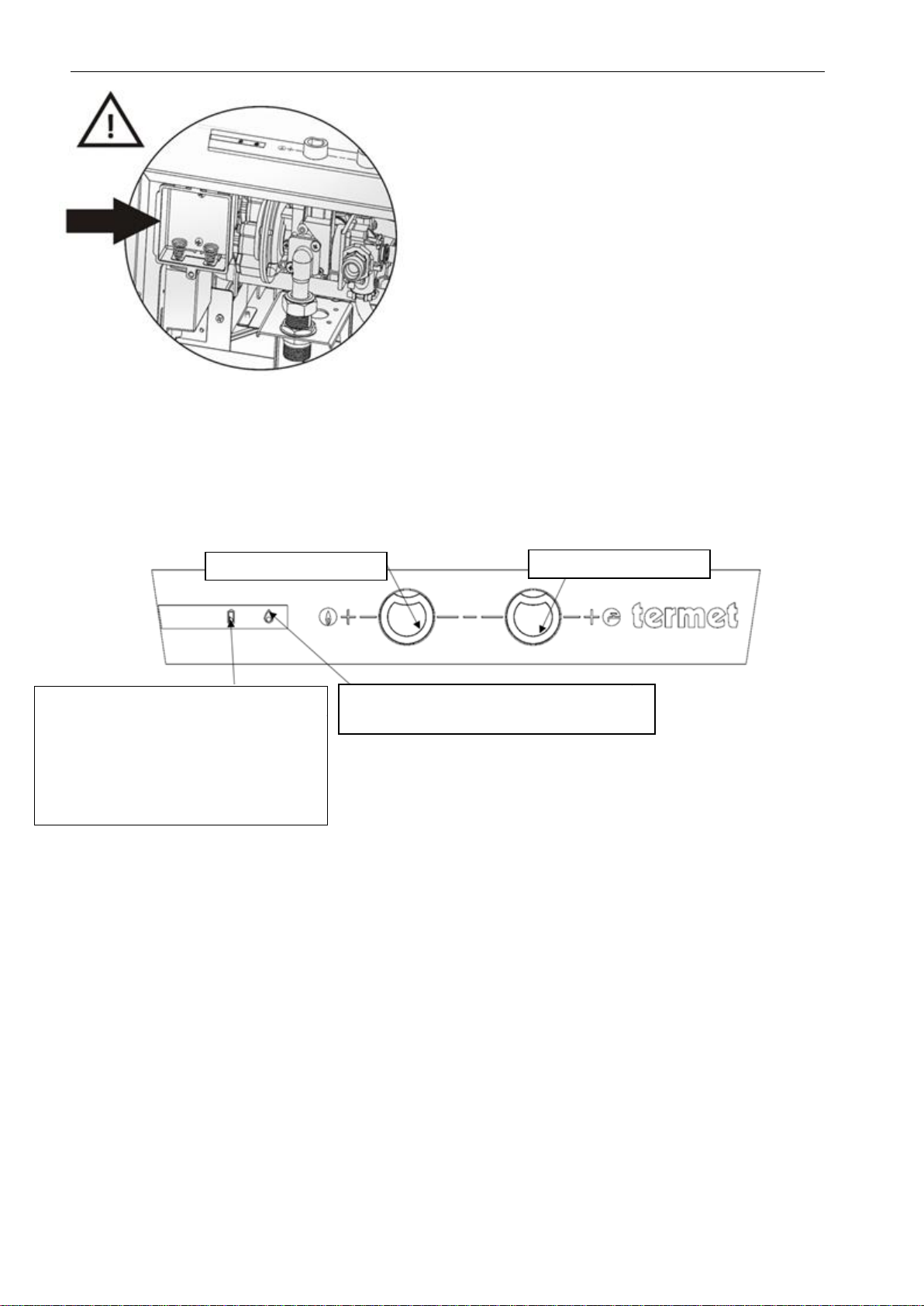

Fig. 4.3.1. Regulation and function elements

LED display –yellow diode

Continues light –water heater is operating

LED display –red diode

Flashing light –signaling not enough

voltage of supply

TERMAQ ELECTRONIC ECO –

discharged batteries

TERMAQ AQUA-POWER ECO –

too little water flow

Gas flow knob

Water flow knob

IO-752:2018/EN 05.12.2018

10

4.4 Water heater switching off

Switching off the water heater is made by turning the gas flow knob into its extreme right (position “0”) (Fig. 4.3.1)

In case of an anticipated long break in the water heater operation, the gas valve on the water heater connection or the

valve on the liquefied gas cylinder, should be shut down.

If in a room, where the water heater has been installed, temperature may decrease below 0ºC, it is necessary to drain

the water heater out of water.

In order to do this, cut off the cold water supply, then undone the nut on the pipe supplying the water into the water

unit and turn on the hot water tap.

5 ADAPTATION OF THE WATER HEATER TO COMBUST OTHER

TYPES OF GAS

The water heater supplied by the manufacturer is designed for combustion of the gas indicated on the rating plate.

If it is necessary to supply the device with other gas than the one for which it was factory adapted, it is necessary to

check for which gas it can be adapted.

Adaptation of the water heater to another type of gas can only be done by the AUTORIZED COMPANY SERVICE.

This activity is not included in the scope of warranty repairs.

Gases to which the water heater can be adapted are given on the rating plate in the category designation of the device:

II2ELsLw3PB/P - which means that they are designed to combust gases from two categories

Gas category

Gas group

Gas type

second

natural gas

G20

GZ-50

third

liquid gas

G30

B

G31

C

5.1 CO emissions

Gas type

CO emissions [ppm]1)

2E-G20

58 ± 5

3P-G30

48 ± 4

3B-G30

48 ± 4

3P/B-G31

490 ± 155

1)CO concentration for maximum gas pressure Pmax.

5.2 Gas consumption values

Gas type

Range of kinetic gas

pressure in the gas

network

kPa (mbar)

GE-19-02, GH-19-02

Gas consumption1)

(dm3/min)

pmin

pnom

pmax

from

to

Natural: 2E-G20

(GZ –50)

1,6

(16)

2,0

(20)

2,5

(25)

35,5

40,5

Liquid: 3PB/P-G30/G31

(B i C)

3,0

(30)

3,7

(37)

4,2

(42)

11

12

1) Consumption of particular types of gas is given for reference gases, in reference conditions (150C, pressure 1013 mbar) allowing for 88% of water

heater efficiency

6 KEEPING IN THE RIGHT

TECHNICAL CONDITION

In order to ensure the appropriate and long-lasting

operation of the water heater, there should be

performed periodical maintenance operations.

Inspections and maintenance operations should be

performed by an authorized company,

at least once a year. The scope of the maintenance

operations is presented below.

Before starting the maintenance operations, the gas

and water supply should be cut off, and then the water

should be drain out from the appliance. Before

cleaning the water heater, first disassembly the burner

and then follow the same way with the heat

exchanger.Heat exchanger cleaning (removing

sediment and scale)

To ensure full gas combustion and retain maximum

heat exchange efficiency in the water heater, it is

recommended to keep the segments of the heat

exchanger in permanent cleanliness.

Cleaning the heat exchanger out of sediments requires

it to be disassembled from the water heater and rinsed

with a strong water stream.

If there is a need of removing the boiler scale from the

ducts of the heat exchanger, this operation should be

IO-752:2018/EN 05.12.2018

11

performed with the use of agents available on market,

according to the recommendations of agent producer.

The scale can also be removed by means of 10-20%

acetic acid, by keeping it in the heat exchanger for about

3 hours. After this operation, the exchanger should be

thoroughly rinsed with clean water.

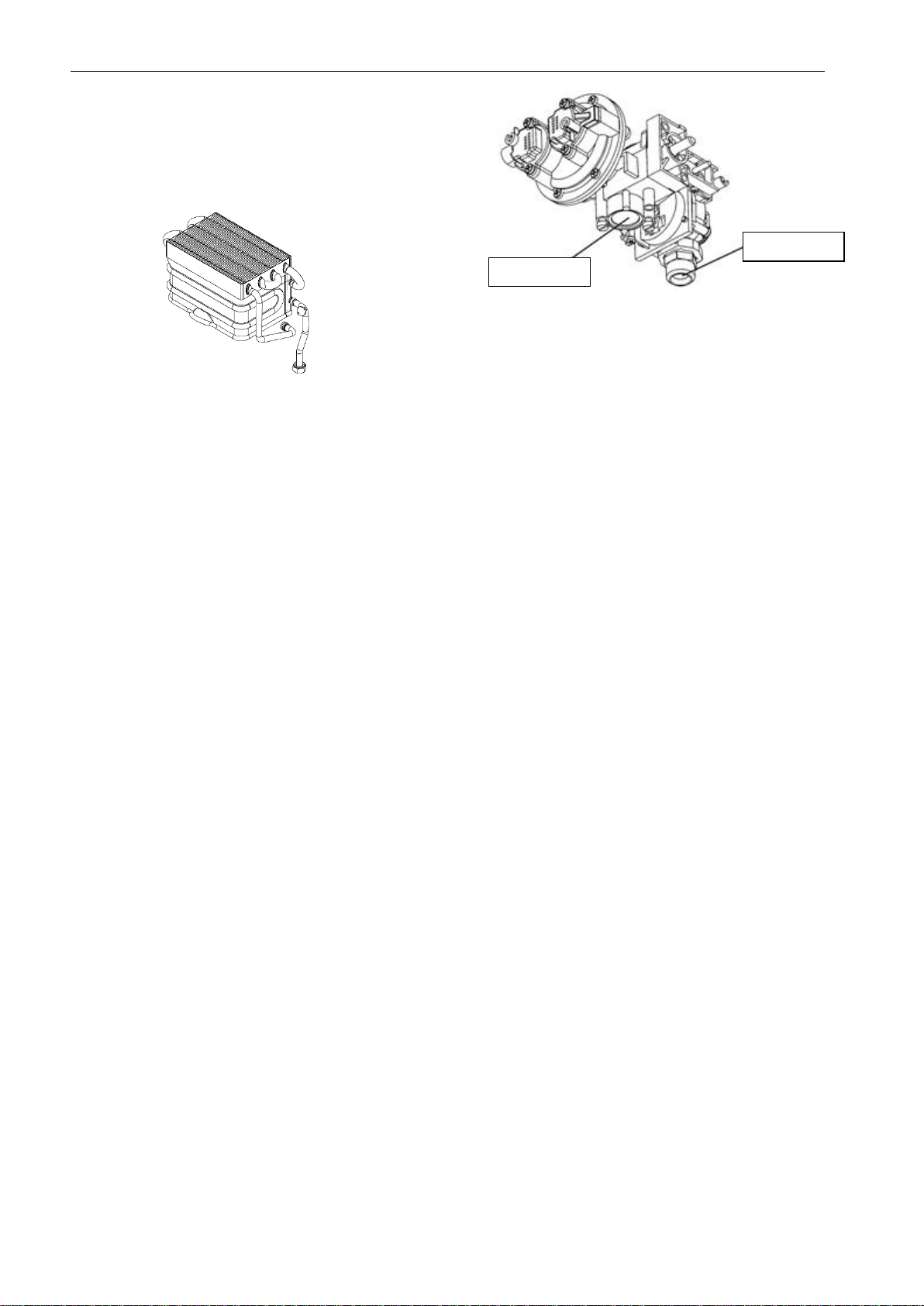

Fig. 6.1.1. Heat exchanger

Do not use the wire brushes, or another brushes with

hard bristle

6.1 Burner maintenance

During the burner maintenance the plates on the

segments should be cleaned by means of soft brush

(not the wire one). Pay attention whether the plates or

segments were not damaged.

6.2 Water filter cleaning

In case of notifying too small stream of water flowing out

from the water heater and difficulty in igniting the burner,

the water supply valve and the gas valve on the

appliance connection should be shut down. Check up

and clean the water filter on the water pipes on the

appliance connection. Sometimes may occur choking of

the internal filter in the water assembly. Then fittings

should be taken out from the water heater. The filter

should be dismounted, cleaned and mounted again

(Fig.5.4.1).

6.3 Gas filter cleaning

In case of finding too poor stream of gas flowing out of

the main burner and difficulties in burner ignition, the

valve on the water supply line and gas valve on the

appliance connection with the gas supplying system

should be shut down. Check up and clean the gas filter

situated on the appliance connection with the gas

supplying system. Occasionally may appear the

situation of choking inside filter of gas –water fittings. In

such case the fittings should be taken out the water

heater. Then take out the filter, clean it and assembly

again. (Fig. 5.4.1)

Fig.6.4.1 Water-gas fittings

6.4 Safety system checking

During every inspection correctness of the protection

systems operation should be checked as well and

tightness of the gas fittings as well.

6.4.1 Checking the protections against

flue gas outflow into the room

Temperature limiter (Illus. 2.2.1.1 item 10) - protection

against gas outflow into the room, is set for the

temperature 85±3°C (GE-19-02, GH-19-02).

In order to verify the correctness of the limiter setting,

the following operations should be performed:

•prepare a metal vessel with a thermometer,

•fill the vessel with a liquid,

•take the limiter out of the holder (unscrew the

screws), put it into a vessel submerging in the liquid

only the metal cap

•heat the liquid up to the temperature of 82°C (GE-

19-02, GH-19-02) –in such temperature the limiter

should not actuate,

•heat the liquid up to 88°C (GE-19-02, GH-19-02) –

in such temperature the limiter should actuate.

A properly operating limiter should disconnect electric

contacts in the temperature range from 82°C to 88°C

(GE-19-02, GH-19-02).

6.4.2 Checking the protection against heat

exchanger overheating

Temperature limiter (Fig. 2.2.1.1 item 11) - protection

against exceeding the upper limit of water temperature

–is set for the temperature 75±3°C (GE-19-02, GH-19-

02). In order to verify the correctness of the limiter

setting, operations as above should be performed.

A properly operating limiter should disconnect electric

contacts in the temperature range from 72°C to 78°C

(GE-19-02, GH-19-02).

During every next re-assembly of the water and gas

system, new seals should be used.

The actions mentioned in section 6 are not covered

by warranty repairs.

water filter

gas filter

IO-752:2018/EN 05.12.2018

12

7 DIAGNOSTICS

During and after the process of production, water heater

is subjected to a whole range of partial and complex

inspections.

In spite of this, during the water heater operation, some

disturbances –that are not caused by the producer –

may occur.

To make easier diagnostics of possible incorrectness in

the water heater operation, in table below essential

information has been collected. Using this information

allows eliminating some unjustified operations during

the water heater disassembly, and thus makes the time

of repair shorter.

Before beginning the water heater repair, it should

be checked if:

•water heater is adapted for the gas currently in use,

•gas pressure is at least minimal,

•negative pressure in chimney duct is within the

range 3 –15 Pa (0.03 - 0.15 mbar).

•battery voltage is adequate

(in TERMAQ ELECTRONIC water heater type )

7.1 Igniting system diagnostics

After turning on the water tap, water flowing through the

water heater should initiate the process of burner

igniting, which stages are presented below:

•clenching/short-circuit/ of the microswitch

connectors, fig. 2.2.1.3 item 3.6,

•sparkling between igniting electrode item 2.1, and

burner segment item.1,

•voltage occurrence on coil I, item 3.5.1 –valve I in the

differential valve opens (valve I in release state is

closed),

•gas ignition on one of the burner segment item 1 –

ionisation current occurrence detected by the

control electrode item.2.2,

•voltage occurrence in coil II item 3.5.2 –valve II in

the differential pressure valve closes (valve II in

release position is open),

•opening the main gas valve caused by pressure

difference over and under the diaphragm in the

differential pressure valve item 3.5,

•gas ignition on the whole burner item 1.

7.2 Igniting system checking

In the case of incorrect ignition, it is recommended to

check the ignition system, according to following

instructions:

1. Check the correctness of electric connections,

2. Connect a voltmeter to the „-” pole:

- In TERMAQ ELECTRONIC ECO water heaters - spring in

battery compartment item 6,

- In TERMAQ AQUA-POWER ECO water heaters –

hydrogenerator’ s wire (white, item 7),

3. Connect a voltmeter to the „+” pole:

- In TERMAQ ELECTRONIC ECO water heaters –metal plate in

battery compartment item 6,

- In TERMAQ AQUA-POWER ECO water heaters –

hydrogenerator’ s wire (red, item 7),

4. Measure the voltage:

- In TERMAQ ELECTRONIC ECO water heaters –the battery

voltage -1,5VDC

- In TERMAQ AQUA-POWER ECO water heaters –the

hydrogenerator’s voltage hydrogenerator’ s at resistance

load 10and at the flow 3l/min - 1,31,6VDC

5. Measure the supply voltage after loading with the

operating ignition system (correct system

operation at the voltage of 0.9-1.5VDC),

6. Check the voltage on the protection against flue

gas outflow into the room item 8 (voltage like on

battery),

7. Check the voltage on the protection against heat

exchanger overheating item 9 (voltage like on

battery),

8. Check the voltage on terminal 9 of the spark

generator, item 5 (voltage like on battery),

9. Close the microswitch connectors item 3.6.

Shorted connectors should cause sparkling

between igniting electrode item 2.1 and burner

segment item 1,

•check the voltage on coil terminals I, item 3.5.1

(correct operation of the system at voltage 0.9-

1.5V),

•after detecting the ionisation current by the

control electrode (after flame appearance),

check the voltage on the clamps of coil II, item

3.5.2 (correct operation of the system at

voltage 0.9-1.5V).

7.3 Checking the coils of

differentia pressure valve

Inspection of possible defects on the electric coils of the

differential pressure valve may be performed by

checking the resistance of the coils.

Method of taking the resistance of the coils:

•take off the muffs from the coils,

•one of the ohmmeter wire connect to the body of

the differential pressure valve,

•the other wire connect to one, and then to the next

muff of the inspected coils, every time taking the

value of the resistance.

Correct resistance values:

Coil I - 39Ω±20%

Coil II - 58Ω±20%

IO-752:2018/EN 05.12.2018

13

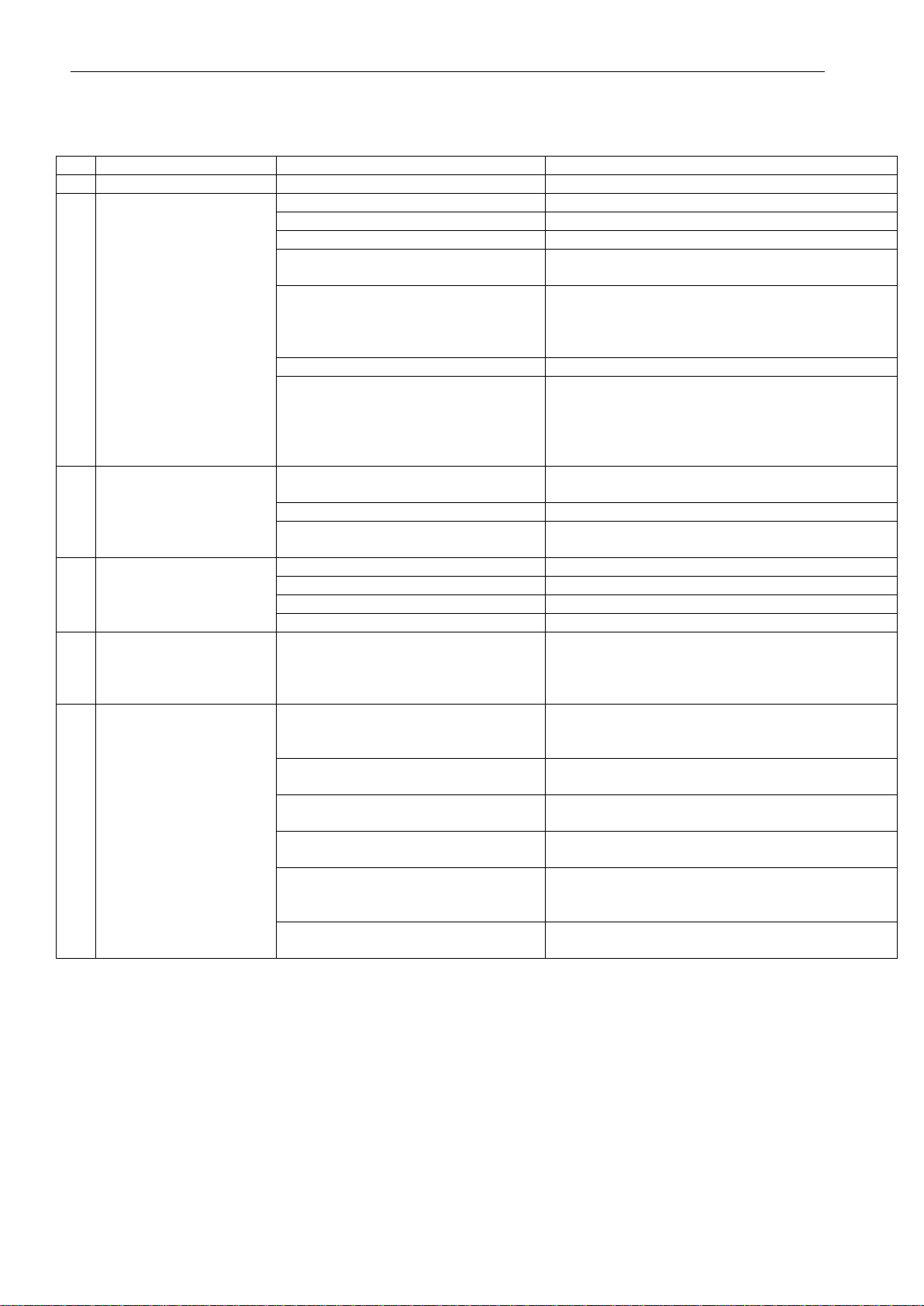

8 DEFECTS - CAUSES AND METHODS OF REMOVING

No.

Symptoms

Causes

Action

1

2

3

4

1.

No spark (no ignition

during water taking)

Electrode wire is disconnected

Correct the connection

Damaged electrode

Check - replace

Spark generator damaged

Check - replace

Dead battery or damaged

hydrogenerator

Check - replace

Microswitch wrongly regulated

Regulate the microswitch by means of screwing

the screw on microswitch lever. Pay attention if

after regulating do not appear sparkling with no

water flow

Water filter clogged (limited flow)

Remove pollutions

Elements in the water-gas fittings

damaged

Water diaphragm damaged

Control system mechanism of valve

head damaged

Replace fittings or damaged elements

2.

Igniting burner does not

ignite from the spark

No gas supply (damaged electrode)

Open the cut-off valve supplying the gas into the

water heater

Vented gas system

Vent the system

Dead battery or damaged

hydrogenerator

Replace

3.

Flame does not spread

throughout the whole

burner

Control electrode wire is disconnected

Correct the connection

Damaged control electrode

Check - replace

Damaged spark generator

Check - replace

Damaged differential pressure valve

Check - replace

4.

Trials of ignition at no

water flow

Microswitch wrongly regulated

Regulate the microswitch by means of screwing

the screw on microswitch lever. Pay attention if

after regulating do not appear delayed ignition

(sparking) during starting-up the water heater

5

Water heater does not

heat water enough

Poor flame on the burner

Check the gas pressure in gas supply network

Check the setting of the gas flow stabiliser

according to p. 5.4

Polluted burner

Remove pollution from the welts and nozzles of

the burner

Polluted radiator in the heat

exchanger

Remove pollution from the radiator fins

Remove the boiler scale

Incorrect gas composition

Check if the main burner, igniting burner and the

fittings are adapted for the gas currently in use

Excessive water flow

Check the small water flow –if water flow exceeds

5,7dm3/min, it is recommended to correct it by

means of regulating screw

Damaged elements of the water-gas

fittings

Replace fittings or damaged elements

IO-752:2018/EN 05.12.2018

14

6.

Water heater overheats

water

Gas flow stabiliser incorrectly set

Regulate the stabiliser, acc. to p. 5.5

Incorrect gas composition

Check if the main burner, igniting burner and

water-gas fittings are adapted for the gas

currently in use

Too little water flow

Check the small water flow –if water flow

exceeds 5,7dm3/min, it is recommended to

correct it by means of regulating screw

Control system mechanism of valve

head is mechanically damaged

Replace damaged elements

7.

Water heater does not

to stop operating after

turning off the water flow

Elements of water-gas fittings

are mechanicallydamaged

Replace fittings or damaged elements

8.

Explosive burner ignition

Too small flame on the igniting

segment

Pipe of igniting burner is choked –clean it up or,

if necessary, replace

In water-gas fittings: gas flowcanalto

igniting segment is choked

Damaged differential valve

Replace fittings or differential pressure valve

9.

Leakage occurring in gas

system of the water

heater

Gasket ring on the inlet to water-gas

fittings is damaged

Replace gasket with a new one

One of the gaskets on the outlet from

water-gas fittings or on the inlet to

burner is damaged

Replace gasket with a new one

Water-gas fittings is mechanically

damaged

Replace fittings or damaged elements

10.

Leakage occurring in

water system of the water

heater

Gasket on the inlet to water-gas

fittings is damaged

Replace gasket with a new one

Gasket on the outlet from water-gas

fittings is damaged

Replace gasket with a new one

One of the gaskets on heat

exchanger connections is damaged

Replace gasket with a new one

Water-gas fittings is mechanically

damaged

Replace fittings or damaged elements

11.

Water heater switches off

during its operating

(during taking the water)

Protection against flue gas inflow into

the room actuates

Check the limiter –if damaged, replace

Check if vacuum in the chimney duct is correct

Protection against exceeding the

upper limit of the water temperature

actuates

Check the limiter –if damaged, replace

Water heater overheats water –action as above

12

Heat exchanger fins

get dirtyin a short time

Wrong chimney draught

Check the chimney ducts

Yellow flame

Check the gas type

Polluted burner (wrong combustion)

Clean the burner

IO-752:2018/EN 05.12.2018

Długa 13, 58-160 Świebodzice,

Infoline +48 74 856 08 01, +48 74 854 68 90

http:// www.termet.com.pl

export@termet.com.pl

[email protected]om.pl

This manual suits for next models

2

Table of contents

Other TERMET Water Heater manuals

Popular Water Heater manuals by other brands

Venus

Venus Domestic VDH 100 user manual

Rinnai

Rinnai REU-KM3237FFUD-E Installation and user manual

Raypak

Raypak FlexGas Hi Delta H 302CD-2342CD Supplemental Installation and Operating Instructions

Quick

Quick B3 Installation and use manual

A.O. Smith

A.O. Smith Water Heater user manual

Eternal

Eternal GU32DV Operator's manual

COSMOGAS

COSMOGAS AGUADENS Installation, operating and maintenance manual

Vaillant

Vaillant VPS R 100/1 M Operating and installation instructions

RED-RING

RED-RING 7000 series Installation & user's instructions

Mex

Mex CUBE 35E instruction manual

Emerson

Emerson insinkerator F-H3N1 Installation, care & use

Philips

Philips AWH1615/51 user manual