OPERATION & MAINTENANCE MANUAL SWE18UF

IV

2.3 MONITOR........................................................................................................................................................17

2.4 ROCKER SWITCH ..........................................................................................................................................18

2.5 START-UP SWITCH .......................................................................................................................................19

2.6 RADIO..............................................................................................................................................................19

2.7 SEAT.................................................................................................................................................................20

2.8 PILOT SAFETY LEVER..................................................................................................................................21

2.9 ENGINE ACCELERATOR SPEED CONTROL LEVER................................................................................22

2.10 PILOT OPERATION......................................................................................................................................22

2.11 AIR DUCT HOOD AND COVERING PARTS..............................................................................................24

2.12 DECALS.........................................................................................................................................................25

3. MACHINE OPERATION....................................................................................................................................26

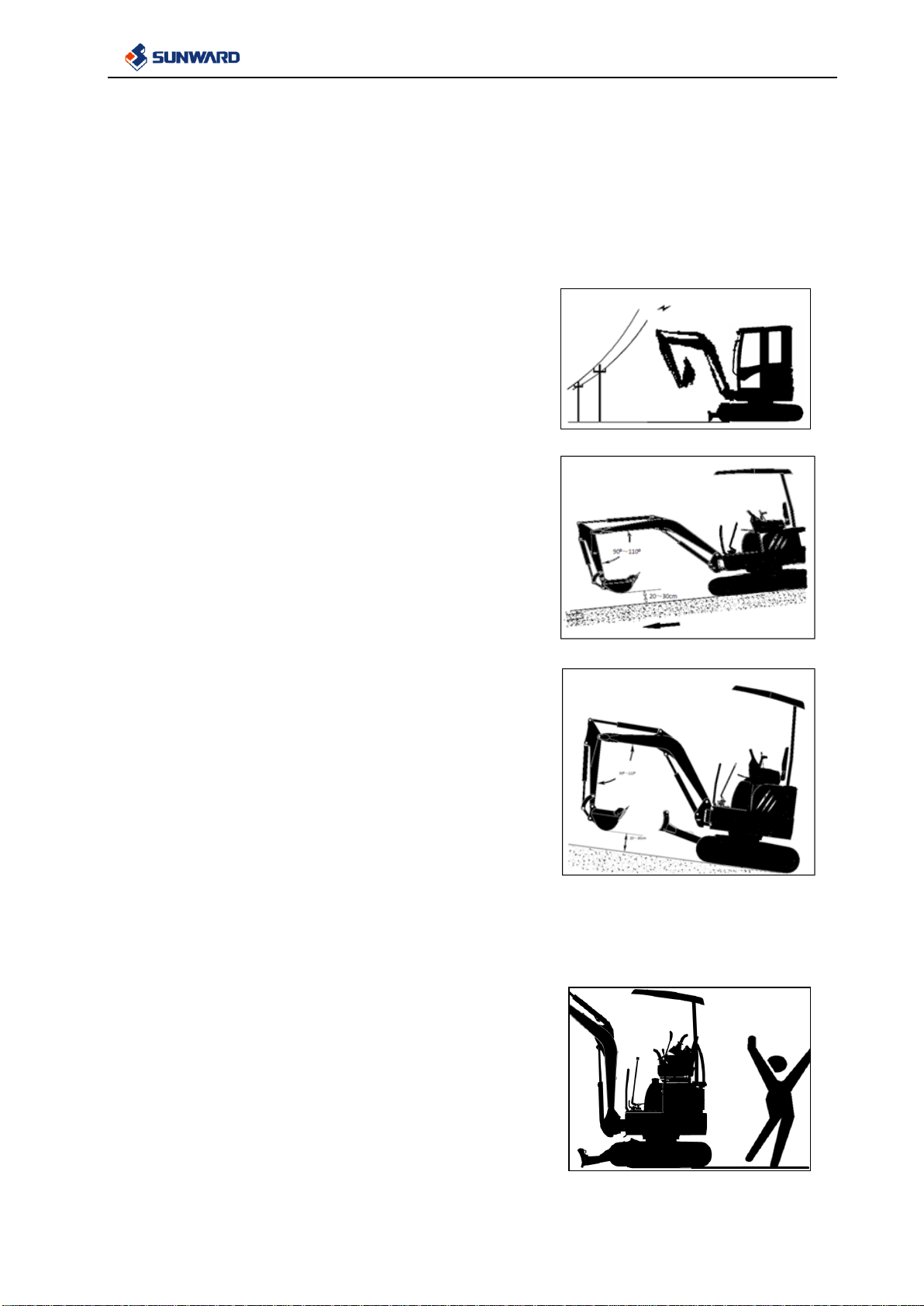

3.1 MACHINE WORKING ENVIRONMENT......................................................................................................26

3.2 RUNNING-IN OPERATION ...........................................................................................................................26

3.3 OPERATING ENGINE ....................................................................................................................................27

3.3.1 Daily Inspection.........................................................................................................................................27

3.3.2 Diesel Engine Inspection...........................................................................................................................28

3.3.3 Electrical Device .......................................................................................................................................28

3.3.4 Air Filter....................................................................................................................................................28

3.3.5 Oil Level in Hydraulic Oil Tank ................................................................................................................28

3.3.6 Before Starting Engine...............................................................................................................................29

3.3.7 Starting Engine..........................................................................................................................................29

3.3.8 Start Engine in Cold Weather....................................................................................................................30

3.3.9 Adjusting Engine Rev.................................................................................................................................30

3.3.10 Stopping Engine.......................................................................................................................................30

3.3.11 Using Auxiliary Battery...........................................................................................................................31

3.4 TRAVEL CONTROL .......................................................................................................................................32

3.4.1 Control Travel with Pedal .........................................................................................................................32

3.4.2 Travel with Handle Control.......................................................................................................................33

3.4.3 Travel Speed ..............................................................................................................................................34

3.4.4 Travel Brake ..............................................................................................................................................34

3.4.5 Key Points of Travelling............................................................................................................................34

3.5 EXCAVATION ................................................................................................................................................37

3.5.1 Working Status...........................................................................................................................................37

3.5.2 Composite Movement of Excavator...........................................................................................................38

3.5.3 Slewing Platform Brake.............................................................................................................................38

3.5.4 Key Points for Excavation .........................................................................................................................38

3.5.5 Excavator Parking.....................................................................................................................................39

3.5.6 Operation on Swampy Ground..................................................................................................................41

3.5.7 Lifting One Side of Crawler by the Boom and Arm...................................................................................41

3.5.9 Operation in Water or Mud.......................................................................................................................42

3.5.10 Backhoe Operation..................................................................................................................................42

3.5.11 Leveling Operation..................................................................................................................................43

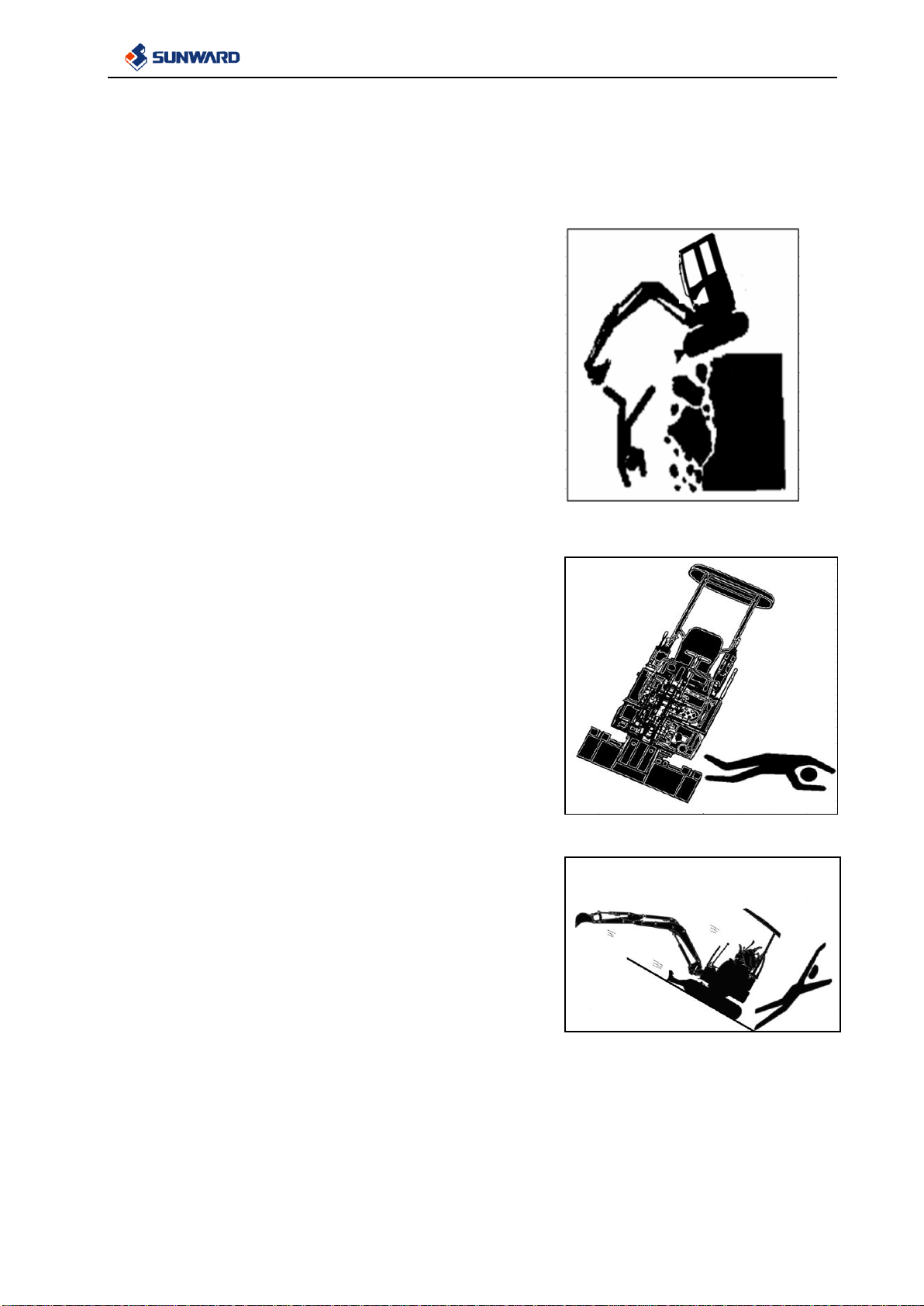

3.5.12 Preventing Collapse.................................................................................................................................43

3.5.13 Operation Tips.........................................................................................................................................43