Resistance and Continuity Measurements

1. Insert the black test lead into the negative COM

terminal and the red test lead into the positive terminal.

2. Set the function switch to the •))) position.

3. Use the multifunction MODE button to select resistance.

4. Touch the test probe tips across the circuit or component under

test. It is best to disconnect one side of the device under test so

the rest of the circuit will not interfere with the resistance reading.

5. For Resistance tests, read the resistance on the LCD display.

6. For Continuity tests, if the resistance is < 100, a tone will

sound.

Clamp size Opening 0.9" (23mm) approx

Diode Test Test current of 0.3mA typical;

Open circuit voltage 1.5V DC typical.

Continuity Check

Threshold <100;

Test current < 1mA

Low Battery Indication “ ” is displayed

Overrange Indication “OL”” is displayed

Measurements Rate 2 per second, nominal

Input Impedance 7.8M(VDC and VAC)

Display 4000 counts LCD

AC Current 50/60Hz (AAC)

AC Voltage bandwidth 50/400Hz (VAC)

General Specs for Insert

Operating Temperature 14 to 122oF (-10 to 50oC)

Storage Temperature -14 to 140oF (-30 to 60oC)

Relative Humidity 90%(0oC to 30oC); 75%

(30oC to 40oC);

45%(40oC to 50oC)

Altitude

Operating: 3000m;

Storage 10,000m

Over voltage Category III 600V

Battery Two 1.5V “AAA” Batteries

Auto OFF approx. 30 minutes

Dimensions/Weight 200x50x35mm/200g

Safety

For indoor use and in

accordance

with Overvoltage Category II, Pollution

Degree 2. Category II includes local level,appliance,

portable equipment, etc., with transient overvoltages

less than Overvoltage Cat.III

Operation

NOTICES: Read and understand all warning and

precaution listed in the safety section of this operation

manual prior to using this meter. Set the function select

switch to the OFF position when the meter is not in use.

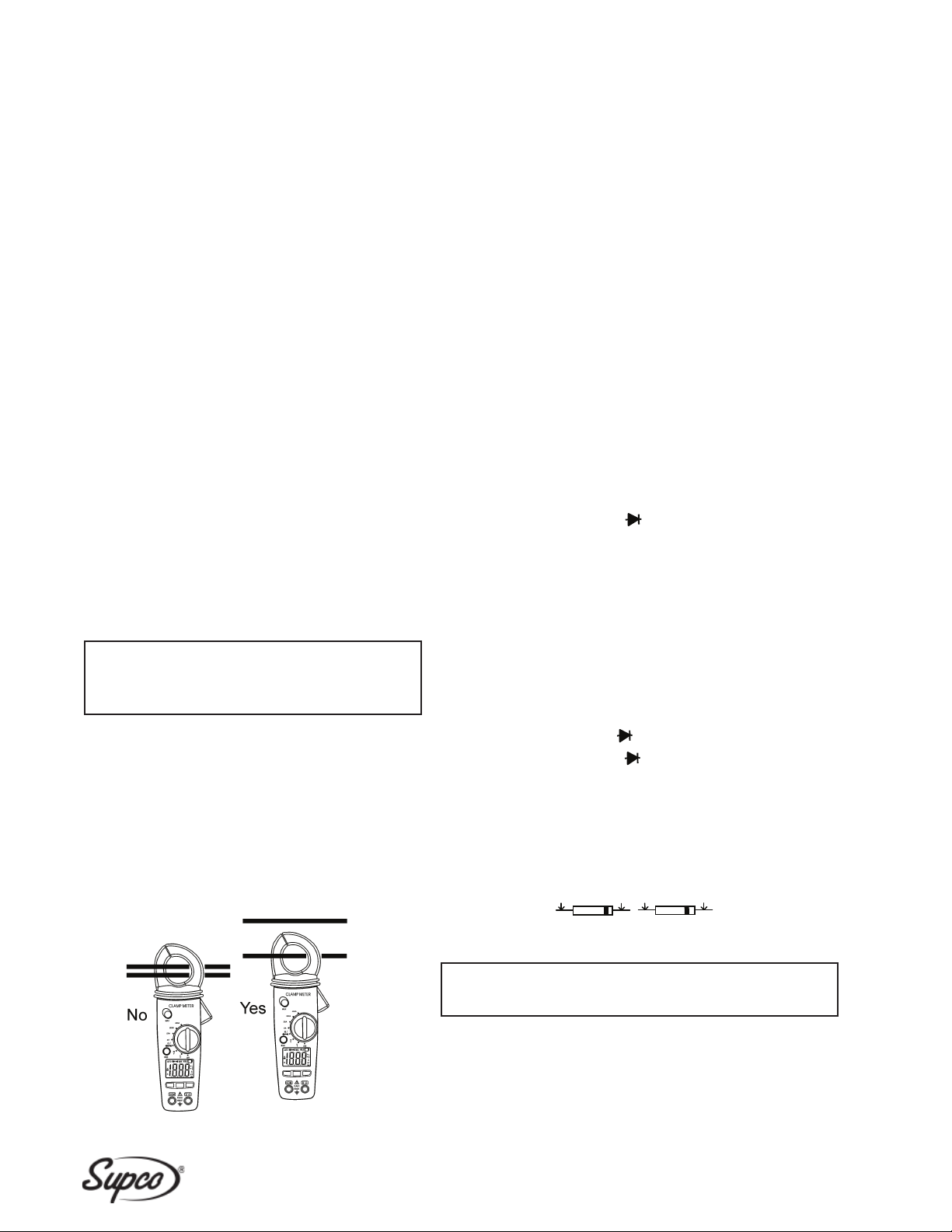

AC Current Measurements

WARNING: Ensure that the test leads are disconnected

from the meter before making current clamp measurements.

1.Set the Function switch to the 400 or40A or 4A range.

If the range of the measured is not known, select the

higher range first then move to the lower range if

necessary.

2. Press the trigger to open jaw. Fully enclose one

conductor

to be measured.

The clamp meter LCD will display the reading.

µA DC/AC CURRENT MEASUREMENTS

1. Insert the black test lead into the negative COM terminal and the

red test lead into the positive µA terminal.

2. Set the function switch to the µA position.

3. Select AC or DC with the MODE button.

4. Remove power from the circuit under test, then open up the circuit

at the point where you wish to measure current.

5. Touch the black test probe tip to the negative side of the circuit.

Touch the red test probe tip to the positive side of the circuit.

6. Apply power to the circuit.

7. Read the current in display.

Capacitance Measurements

WARNING:

To avoid electric shock, disconnect power to the unit

under test and discharge all capacitor before taking any capacitance

measurements. Remove the batteries and unplug the line cords.

1. Set the rotary function switch to the cap position.

2. Insert the black test lead banana plug into the negative (COM) jack.

Insert the red test lead banana plug into the positive (V) jack.

3. Touch the test leads to the capacitor to be tested.

4. Read the capacitance value in the display

DC/AC Voltage Measurements

1. Insert the black test lead into the negative COM terminal

and the red test lead into the positive Vterminal.

2. Set the function switch to the V position. etc., with

transient overvoltages less than Overvoltage Cat. III

3. Select AC or DC with the MODE button.

4. Connect the test leads in parallel to the circuit under test.

5. Read the voltage measurement on the LCD display.

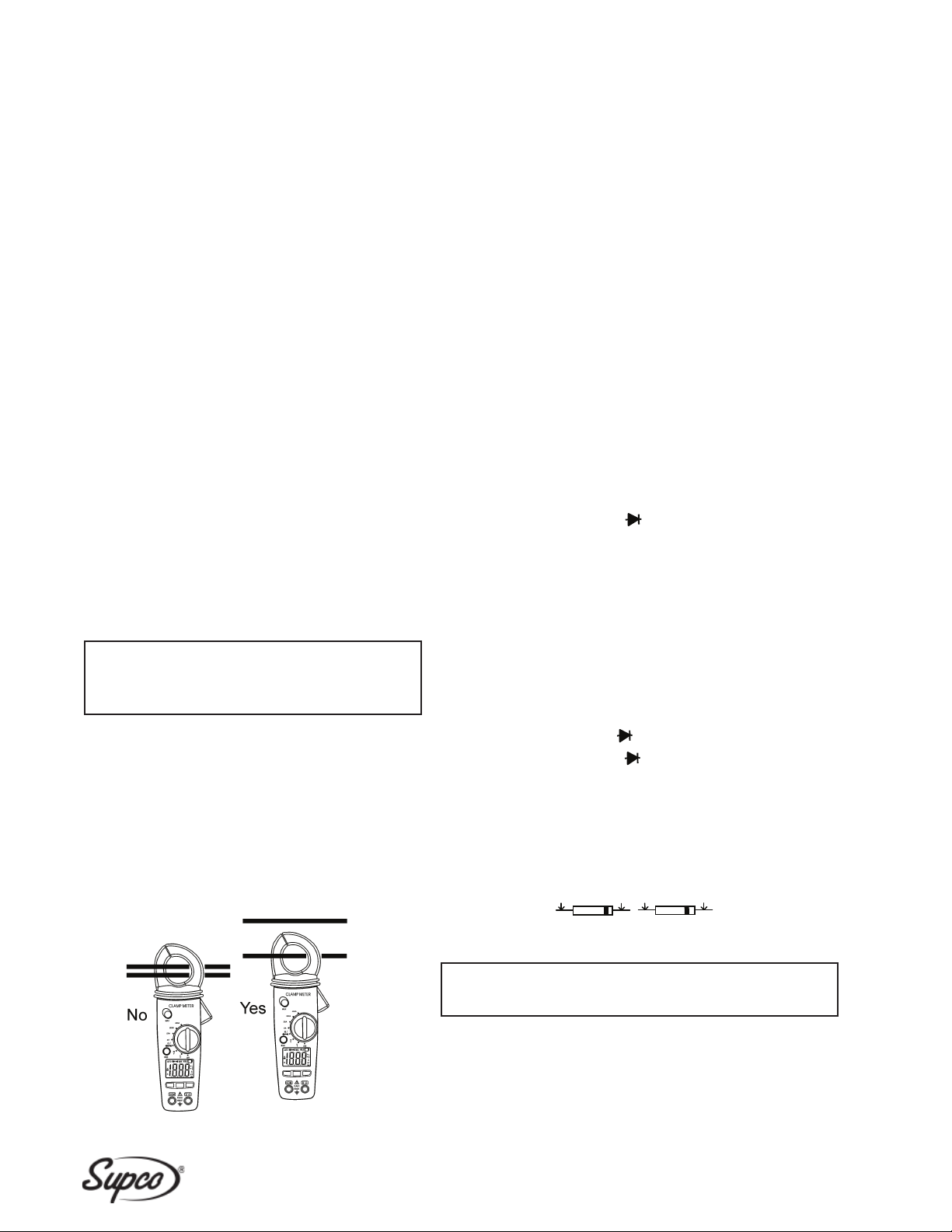

Diode Measurements

1. Insert the black test lead banana plug into the negative COM jack

and the red test lead banana plug into the positive diode jack.

2. Turn the rotary switch to the •))) position.

3. Press the MODE button until “ “ appears in the display.

4. Touch the test probes to the diode under test. Forward voltage will

indicate 0.4V to 0.7V. Reverse voltage will indicate “OL”. Shorted

devices will indicate near 0mV and an open device will indicate

“OL”in both polarities.

Red Black Black Red

Probe Probe Probe Probe

Forward test Reverse test

SEALED UNIT PARTS CO., INC.

P.O. Box 21, 2230 Landmark Place, Allenwood, N.J. 08720 USA

(732)223-6644 • Fax (732)223-1617