Updated: 15 November, 2011 Page 2 REF: REI-85-0045

1. PRECAUTIONS____________________________________________________________________________ 3

1.1 INSTALLATION ______________________________________________________________________ 3

1.2 SAFETY MATTERS ___________________________________________________________________ 3

1.3 DO’s & DON’Ts_______________________________________________________________________ 3

2. INTRODUCTION __________________________________________________________________________ 4

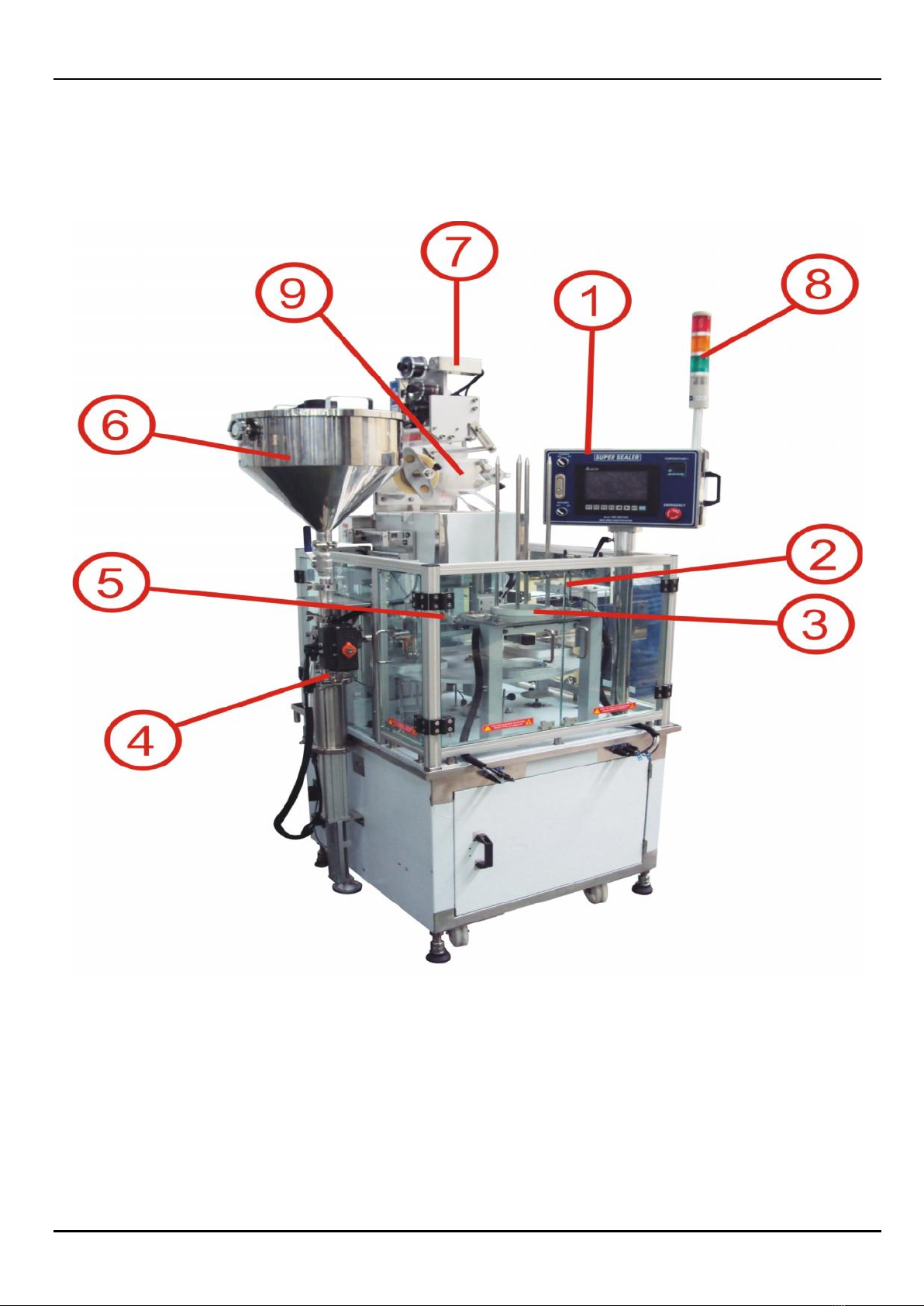

3. MAIN PARTS______________________________________________________________________________ 5

3.1 SPECIFICATIONS ________________________________________________________________________ 6

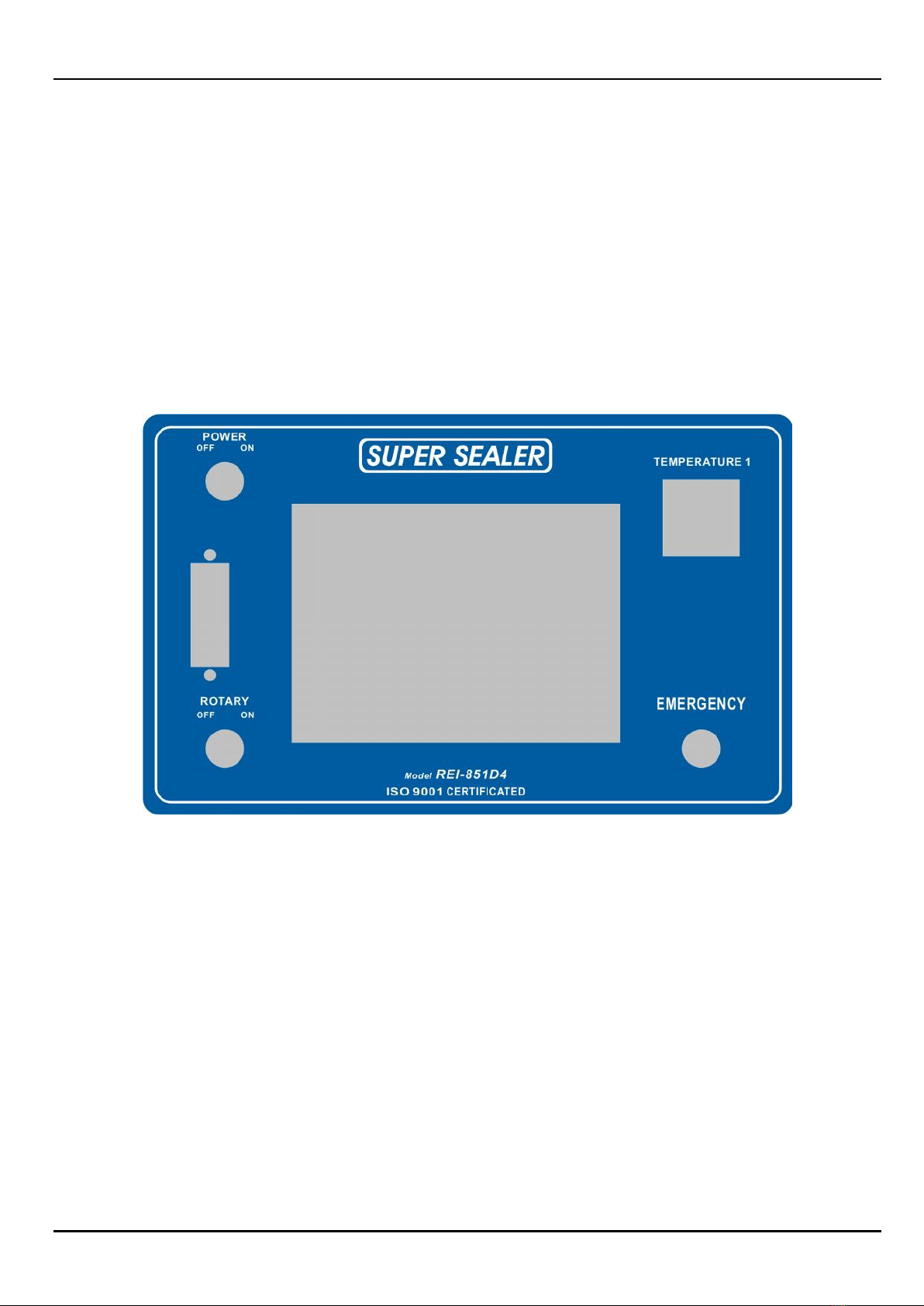

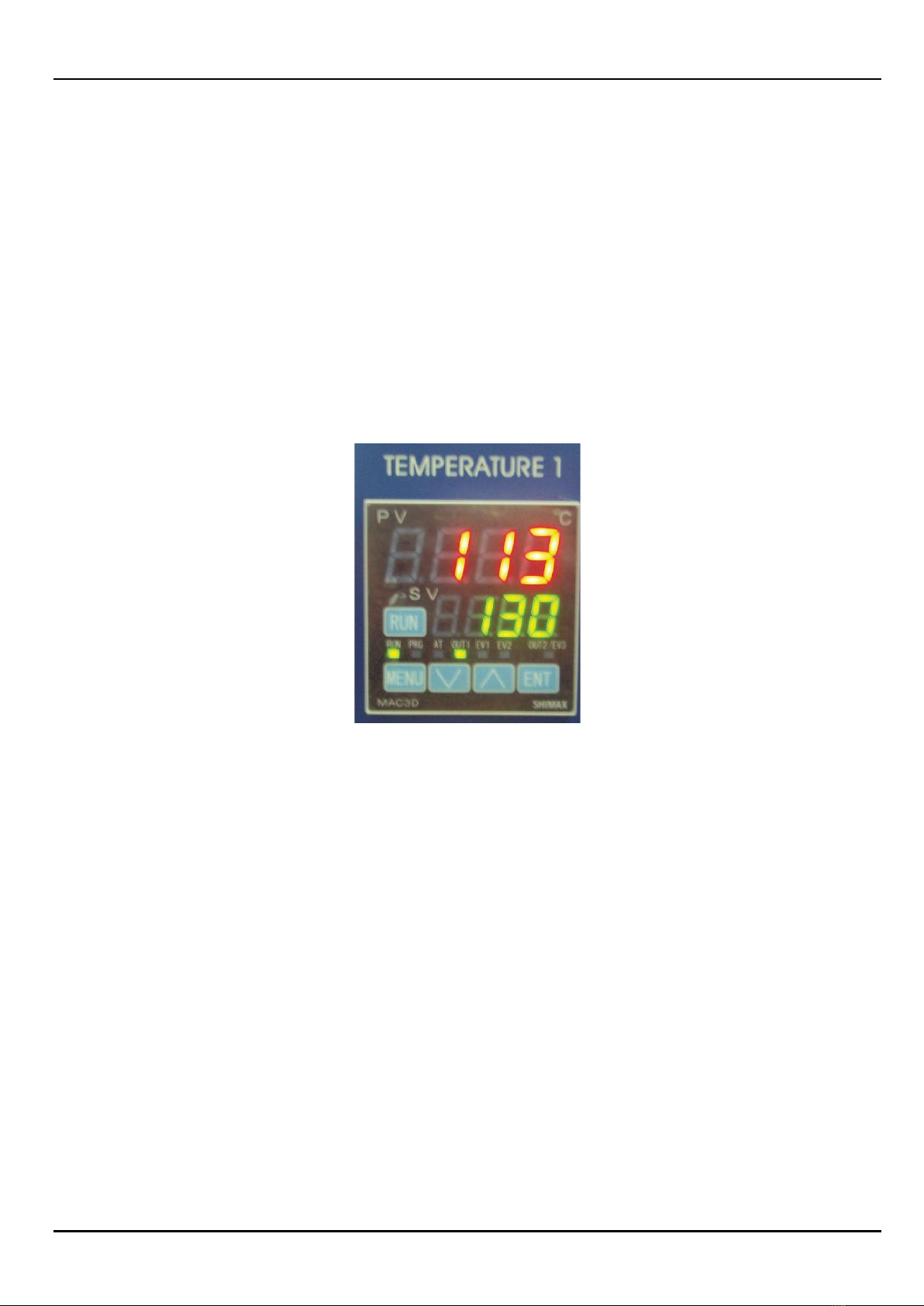

4. CONTROL PANEL _________________________________________________________________________ 6

5. ROLL FILM SET-UP _______________________________________________________________________ 7

5.1 FILM SCHEMATICS______________________________________________________________________ 8

5.2 PRINTED FILM ADJUSTMENT ____________________________________________________________ 8

6. DATE PRINTER __________________________________________________________________________ 10

6.1 PRINTER RIBBON SETTING _____________________________________________________________ 10

7. MOULD REMOVAL & REPLACEMENT______________________________________________________ 10

7.1 LOWER MOULD ________________________________________________________________________ 11

7.2 UPPER MOULD _________________________________________________________________________ 11

8. FILLER _________________________________________________________________________________ 12

8.1 HOPPER LEVEL ________________________________________________________________________ 13

8.2 VOLUME ADJUSTMENTS________________________________________________________________ 13

9. OPERATION _____________________________________________________________________________ 13

9.1 FUNCTION SELECTION _________________________________________________________________ 13

9.2 MANUAL OR AUTOMATIC OPERATION__________________________________________________ 14

9.3 FILM SETTING (ENCODER OR SENSOR OR TIMER) ______________________________________ 14

9.4 SEALING TIME _________________________________________________________________________ 15

9.5 FILLER ________________________________________________________________________________ 16

9.5.1 FILLER RINSING _____________________________________________________________________ 16

10. MAINTENACE _________________________________________________________________________ 17

10.1 DAILY MAINTENANCE ______________________________________________________________ 17

10.2 WEEKLY MAINTENANCE _________________________________________________________ 17

10.3 MONTHLY MAINTENANCE ___________________________________________________________ 17

11. ERROR CODES AND TROUBLE SHOOTING _______________________________________________ 17

12. ELECTRICAL DIAGRAMS _______________________________________________________________ 21

13. LADDER DIAGRAM ____________________________________________________________________ 23

14. STATEMENT___________________________________________________________________________ 24

15. WARRANTY____________________________________________________________________________ 24

16. LIABILITY_____________________________________________________________________________ 24