9

If the winch motor labors and then

stops, the load is too great.

Evidence of this will be a motor

almost too hot to touch. Repeated

occurrence of this condition indi-

cates that the load exerted on your

winch is beyond its capacity and

may burn out the winch motor. Use

of the accessory pulley block, P/N

2227, will increase the winch‘s

capacity.

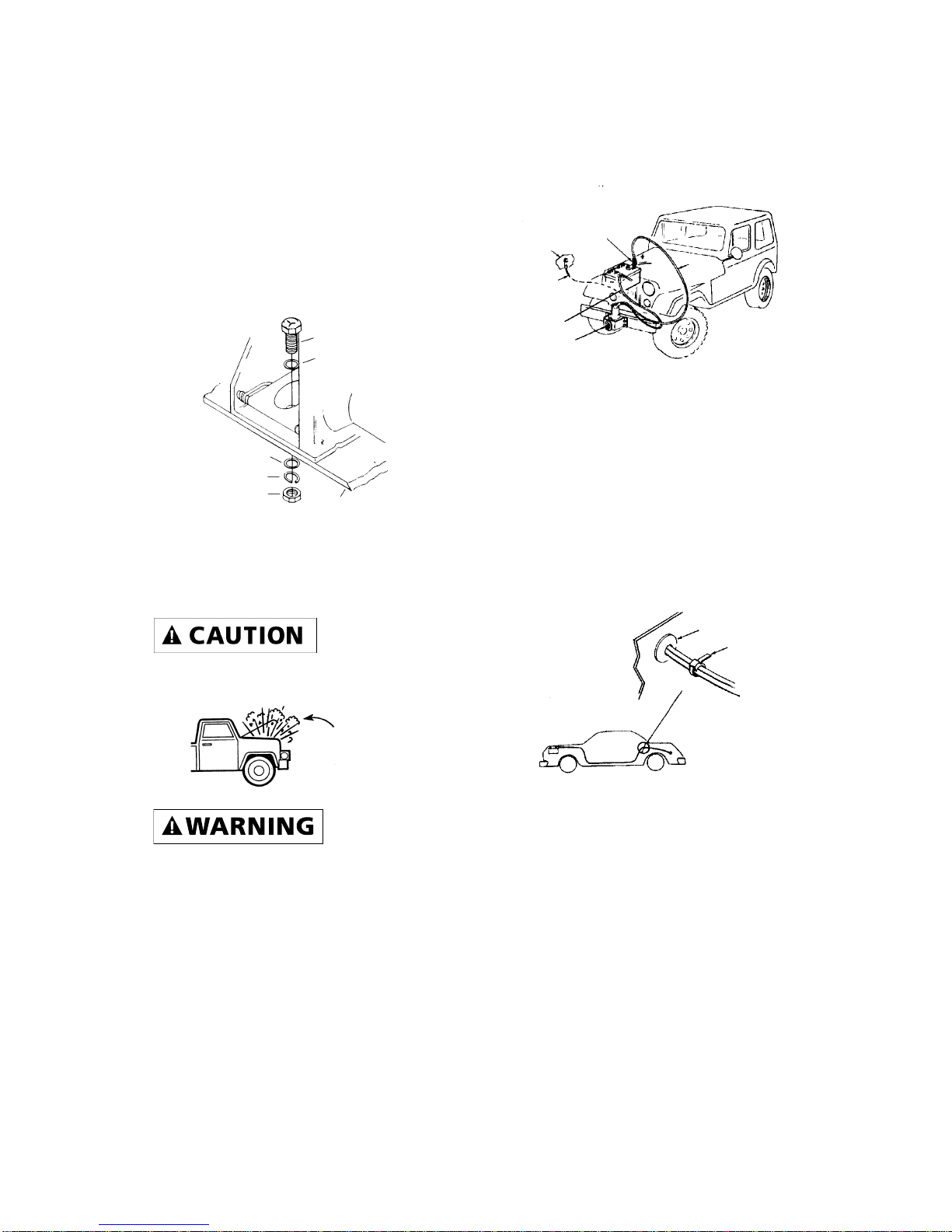

MOTOR DOES NOT OPERATE

Follow these steps in order. Make

sure your vehicle engine is running

and then try operating your winch

after each step.

1. Remove switch, then replace it on

the motor, making certain that it

is aligned properly over brass

motor connectors and that thumb

screw is snug.

2. If motor does not operate, check

all electrical connections on bat-

tery and ground, making sure

that they are clean and tight.

3. Check the wiring harness to

determine if all insulation is

intact. Damaged insulation could

cause a short circuit.

TIPS F0R EXTENDING THE LIFE OF

YOUR WINCH

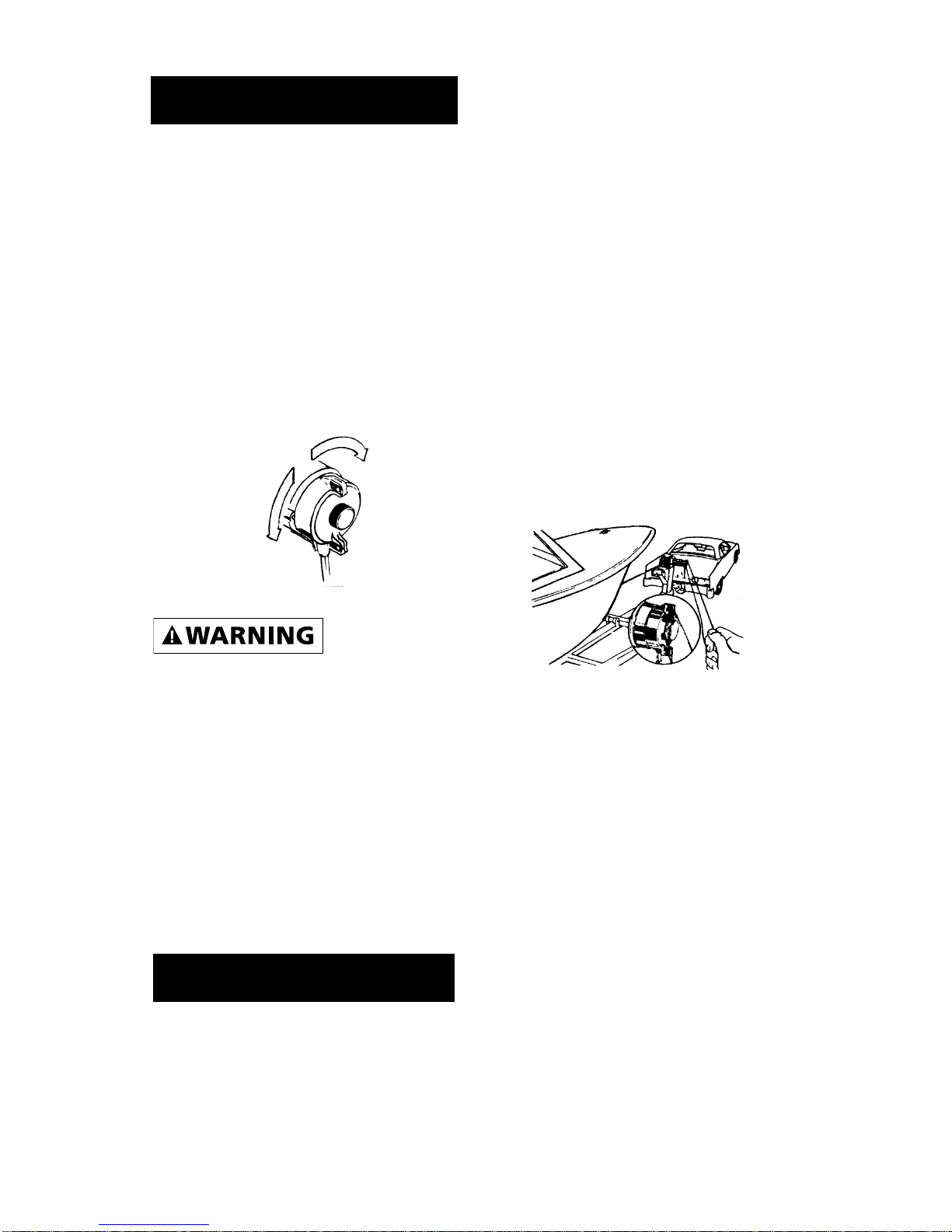

1. KEEP A TIGHTLY AND EVENLY

WOUND WIRE ROPE DRUM. Do

not allow the wire rope to

become loosely wound. A loosely-

wound drum allows a wire rope

under load to work its way down

into the layers of wire rope on

the drum. When this happens,

the wire rope may become

wedged within the body of the

windings, damaging the wire

rope. To prevent this problem,

keep the wire rope tightly and

evenly wound on the drum at all

times. During winching, periodi-

cally check to see that the wire

rope is winding on evenly. A

good practice is to rewind the

wire rope under tension after

each use. One way to do this is to

attach the hook to a stationary

object at the top of a small hill or

incline and winch your vehicle up

the incline.

2. DO NOT ALLOW MOTOR TO

OVERHEAT. Remember, the

winch is only for intermittent use.

During long or heavy pulls the

motor will get hot. The internal

parts will be hotter than the case.

To check the motor temperature,

stop winching and carefully touch

the motor. If the motor is uncom-

fortably warm, allow the motor

to cool before continuing. Keep

the engine running to recharge

the battery during this break.

3. USE A PULLEY BLOCK FOR

HEAVY LOADS. To maximize

winch and wire rope life, use a

pulley block, P/N 2227, to double-

line heavier loads.

4. The pull required to start a load

moving is often much greater

than the pull required to keep it

moving. AVOID FREQUENT

STOPPING AND STARTING

DURING A PULL.

TROUBLE SHOOTING

Figure 15