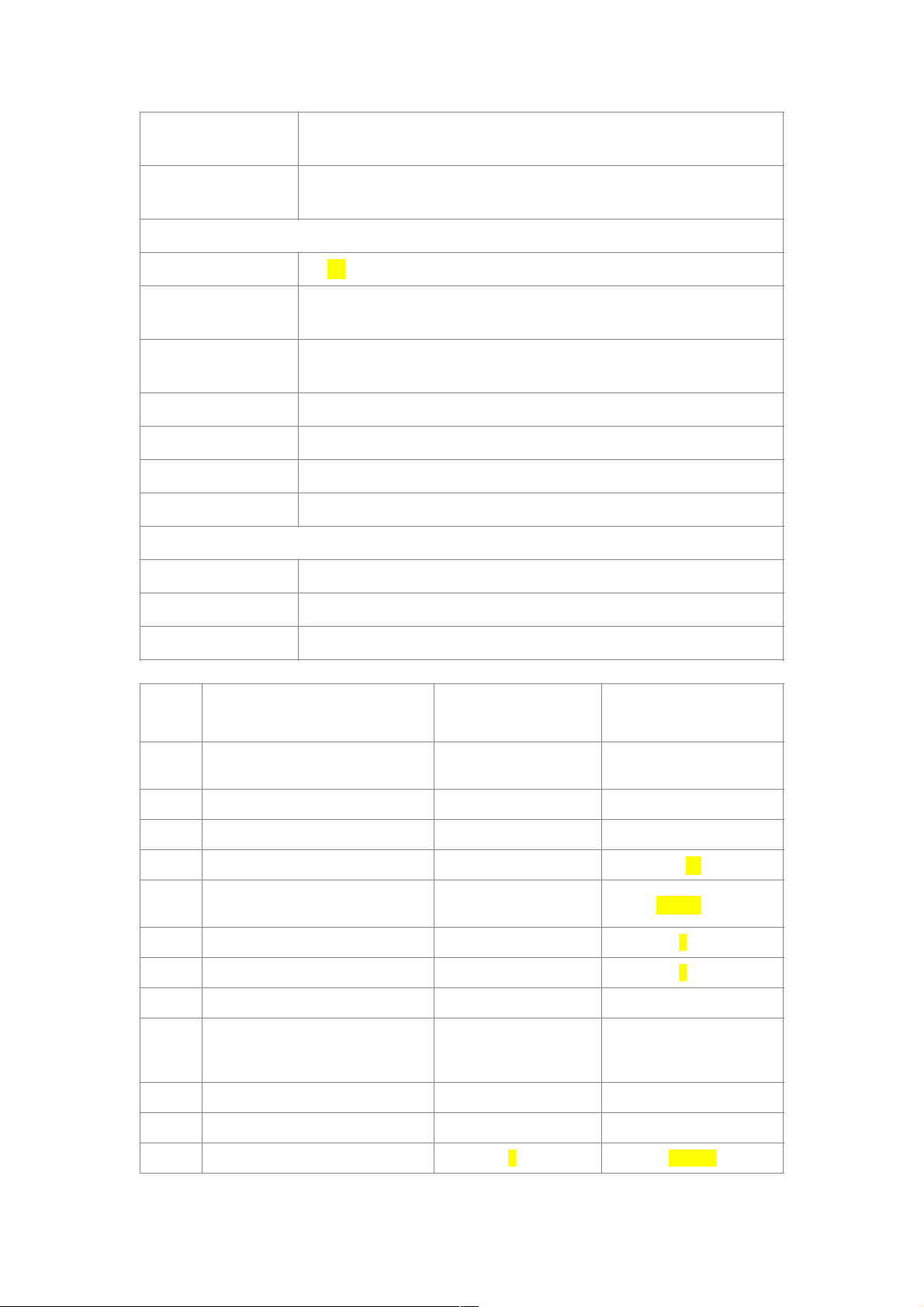

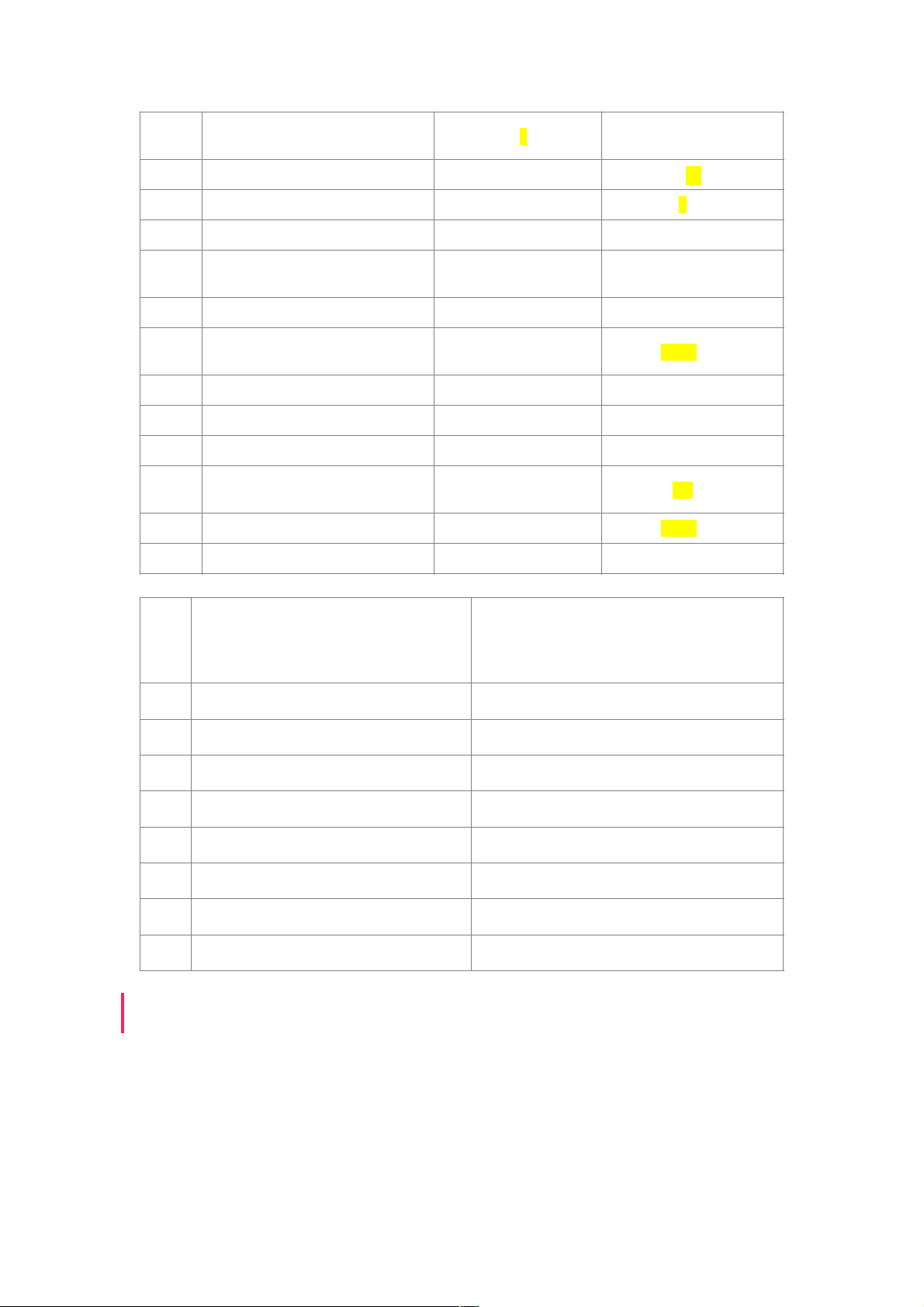

2.2 Torque specifications of important screws

2.3 The top speeds under different battery capacities

2.4 Bike composition

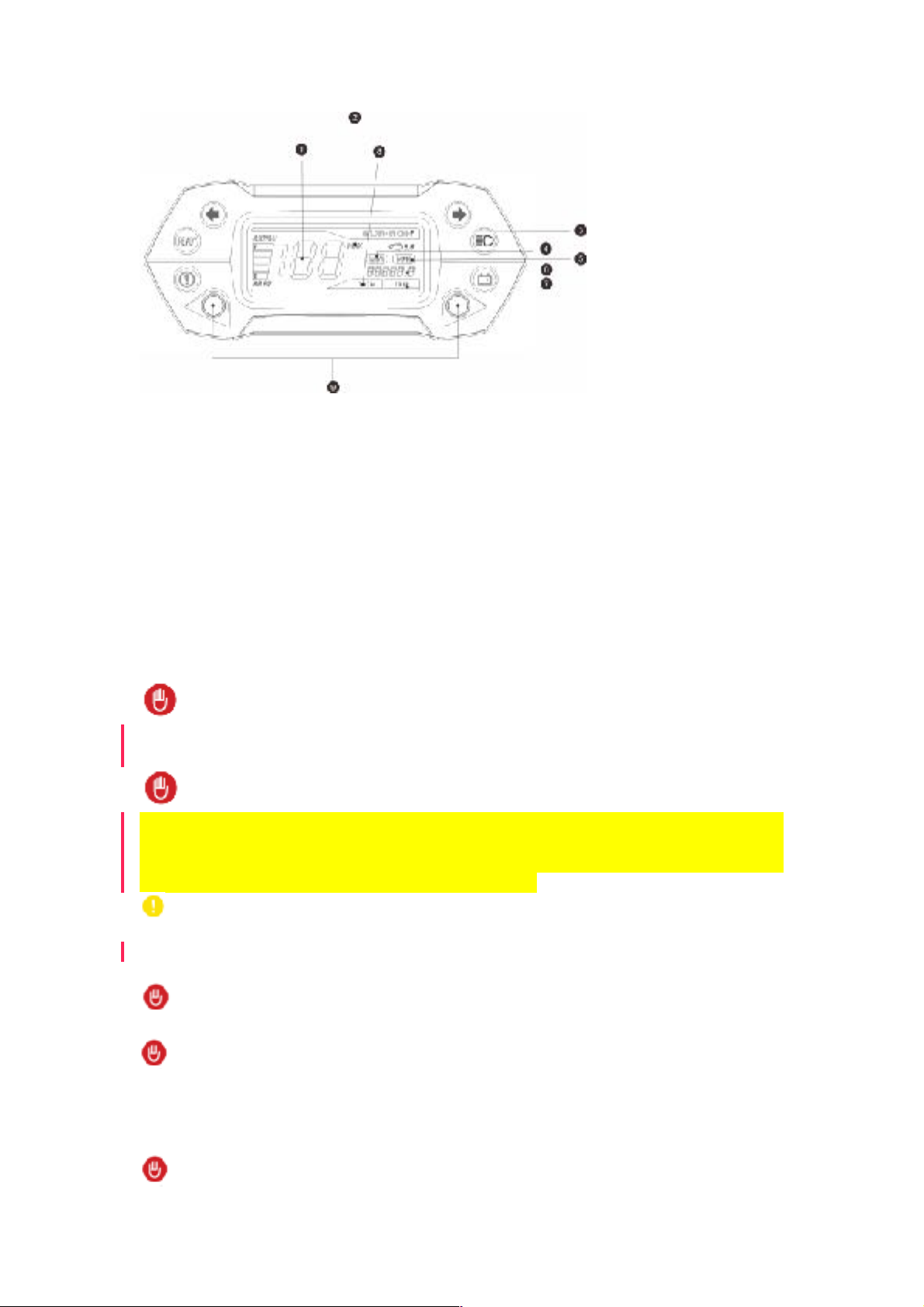

3. Bike operation

4. LIGHT BEE repair tools and preparation work

4.1. LIGHT BEE repair tools

4.2. LIGHT BEE fixing

5. Battery dismount and mount

6. Absorber dismount, mount, and adjustment

6.1 Adjust the compression damping of front absorber

6.2 Adjust setting of absorber

6.3 Absorber lubricating

6.4 Front absorber dismount and mount

6.5 Rear absorber dismount and mount

6.6 Disassembly of rear absorber

7. Check, dismount, mount of the headset

7.1 Check stroke gap of headset

7.2 Disassemble the headset

8. Disassemble and assemble handle bar assembly

9. Wheel checking

9.1 Tire checking

9.2 Rim checking

10. Braking system checking and maintenance

10.1 Brake checking

10.2 Maintenance

10.3 Brake lever dismount and mount

10.4 Brake pump dismount and mount

10.5 Brake clipper dismount and mount

10.6 Brake clipper adopter dismount and mount

10.7 Front brake assembly dismount and mount

10.8 Rear brake assembly dismount and mount

11. Bike body dissemble and assemble

11.1 Mid. Bushing dismounting and mounting

11.2 Motor side-cover dismounting and mounting

11.3 Motor side-cover dismounting

11.4 Disassemble and assemble first level transmission belt

11.5 Disassemble and assemble left pedal assembly

11.6 Disassemble left pedal assembly

11.7 Disassemble and assemble right pedal assembly

11.8 Disassemble pedal assembly

11.9 Disassemble and assemble guard plate under DC motor

11.10 Disassemble and assemble guard plate under controller

11.11 Disassemble and assemble air circuit breaker combination

11.12 Disassemble air circuit breaker combination

11.13 Disassemble and assemble USB and electric control lock combination

11.14 Disassemble USB and electric control lock

11.15 Disassemble and assemble DC motor assembly

11.16 Disassemble and assemble tailstock assembly

11.17 Disassemble tailstock assembly

11.18 Disassemble and assemble left and right limited block of battery

11.19 Disassemble and assemble horn

11.20 Disassemble and assemble back shield

11.21 Disassemble and assemble rear wheel assembly