4

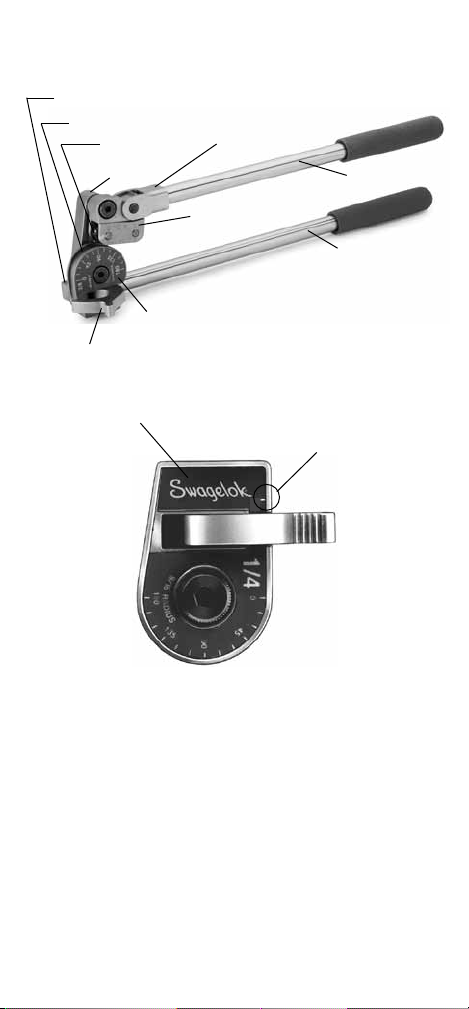

Introduction

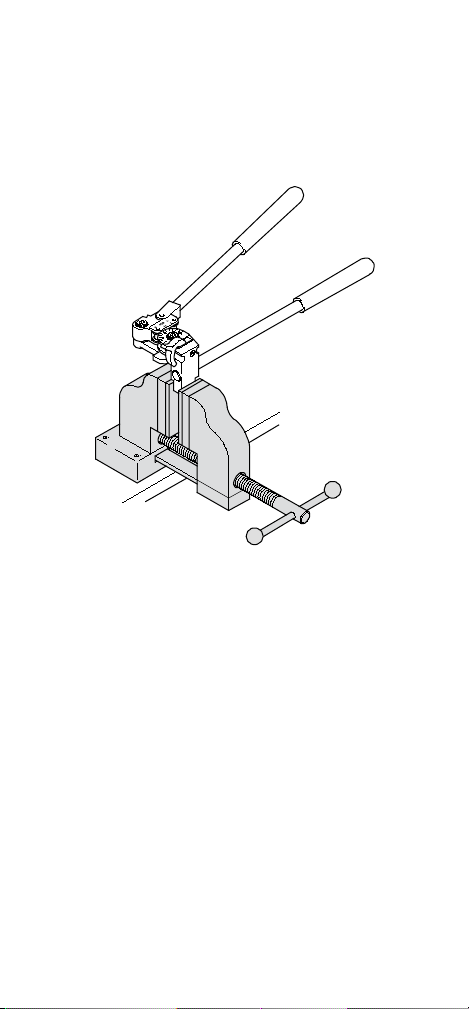

Swagelok®hand tube benders provide consistent,

high‑quality bends in tubing made from most materials

used with Swagelok tube ttings.

Read this manual before using the hand tube bender.

Tubing Data

■ The Swagelok hand tube bender bends 1/8,

1/4, 5/16, 3/8, and 1/2 in., and 3, 6, 8, 10, and 12

mm outside diameter tubing in a variety of wall

thicknesses.

■ Tubing should be free of scratches and suitable for

bending.

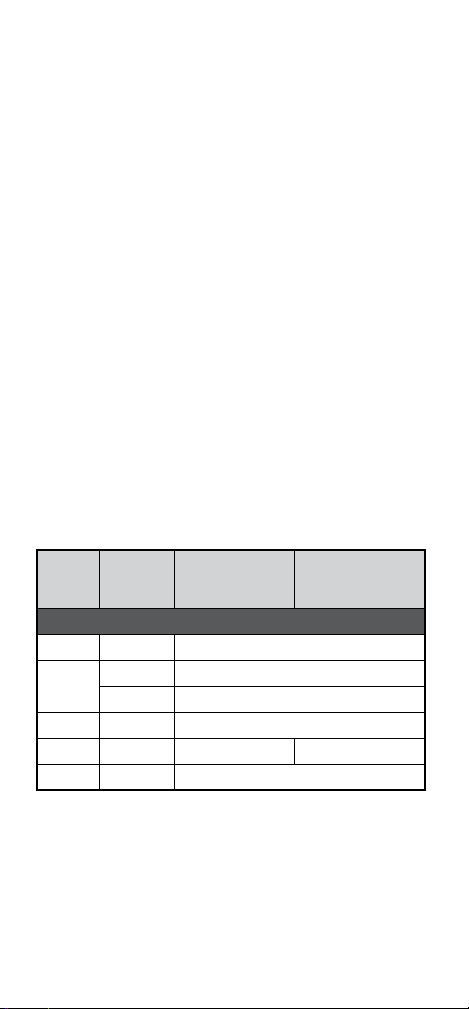

Suggested Tubing Ordering Information

Fractional Tubing

High‑quality, soft‑annealed, seamless carbon steel

hydraulic tubing ASTM A179 or equivalent. Hardness

72 HRB (130 HV) or less.

Fully annealed, high‑quality (Type 304, 316 etc.)

(seamless or welded and drawn) stainless steel

hydraulic tubing ASTM A269 or A213, or equivalent.

Hardness 90 HRB (200 HV or less).

Tube

OD

Approx

Bend

Radius

Carbon Steel

Wall Thickness

Min/Max

Stainless Steel

Wall Thickness

Min/Max

Dimensions, in.

1/8 9/16 0.028/0.035

1/4 9/16 0.028/0.065

3/4 0.028/0.065

5/16 15/16 0.035/0.065

3/8 15/16 0.035/0.065 0.035/0.083

1/2 1 1/2 0.035/0.083