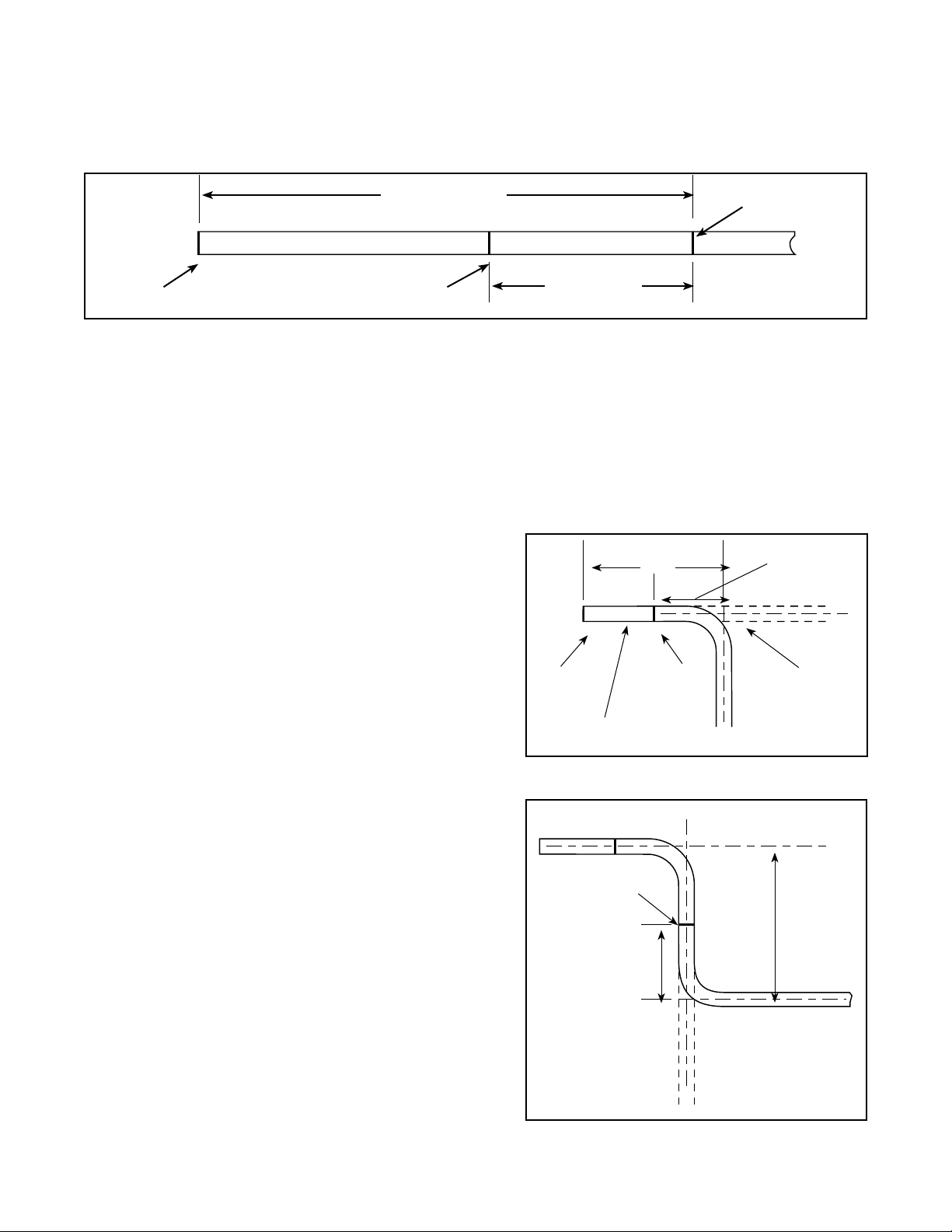

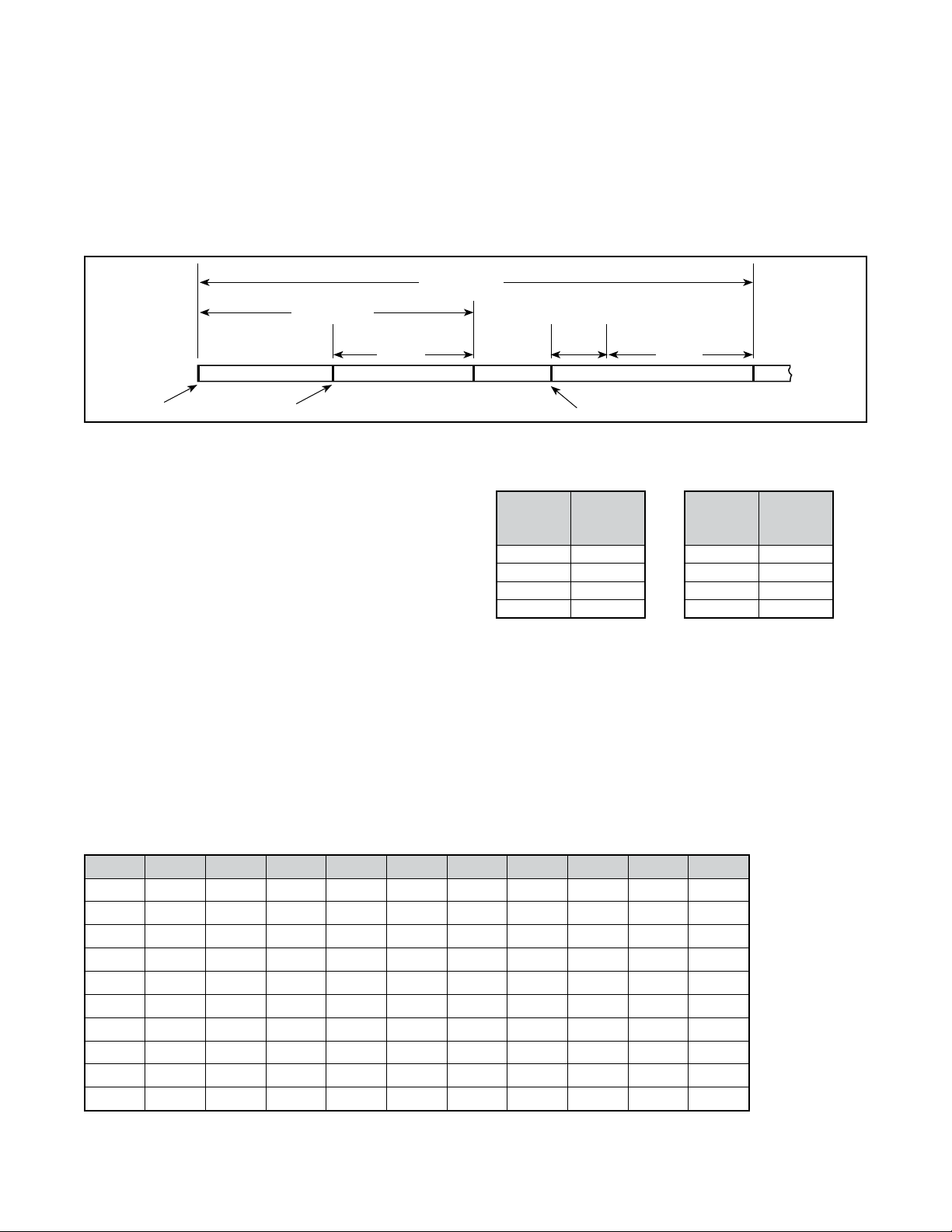

Multiple 90° Bends

The Premeasure Method

1. Follow Steps 1 to 3 for a Single 90° Bend. (See page 8.)

2. From the reference mark at the end of the tubing, measure the desired length for the second bend and make a

measurement mark.

3. Subtract the bend deduction distance (see Table 2) and the adjustment factor (see Table 3) from the second

measurement mark, and make the second bend mark.

– 9 –

First Measurement

Length 18 in.

Bend Deduction Distance

9-7/8 in.

Gain

Adjustment

Factor

2 9/16 in.

Reference

Mark

Bend

Mark

Bend

Mark

Second Measurement

Length 36 in.

Bend Deduction

Distance

9-7/8 in.

Illustration 4 – Multiple 90° Bends

EXAMPLE: Using 1 1/2 in. OD tubing, make two 90° bends

with a measured length distance of 18-in. between bend

marks. (See Illustration 4.)

1. From the reference mark at the end of the tubing,

measure 18 in. and make a measurement mark.

2. The bend deduction distance for 1 1/2 in. OD tubing in

Table 2 is 9-7/8 in.

3. 18 in. – 9-7/8 in. = 8-1/8 in. Make the first bend mark

at 8-1/8 in.

4. Add the first and second measurement lengths. 18 in. +

18 in. = 36 in.

5. From the reference mark at the end of the tubing,

measure 36 in. and make a second measurement mark.

6. The bend deduction distance for 1 1/2 in. OD tubing is

9-7/8 in., and the adjustment factor for a 90° bend in

Table 3 is 2-9/16 in.

Table 2 – Bend Deduction Distance

Table 3 – Gain Factors for 0 to 90° Bends

Example:Thegainfactorfora90°bendis0.4292.

To calculate the gain for 90° bend multiply the gain factor times the bend radius.

Example:0.429236in.=2.58,orabout2-9/16in.gain

7. 36 in. – 9-7/8 in. – 2-9/16 in. = 23-9/16 in.

8. From the reference mark at the end of the tubing,

measure 23-9/16 in. and make a second bend mark.

9. Bend tubing.

Note: Follow the above steps when using metric

measurements.

Tube

OD

in.

Bend

Deduction

in.

1 6-1/2

1 1/4 8-3/16

1 1/2 9-7/8

2 12-5/8

Tube

OD

mm

Bend

Deduction

mm

25 177

32 213

38 247

50 318

0° 1° 2° 3° 4° 5° 6° 7° 8° 9°

0° 0.0000 0.0000 0.0000 0.0000 0.0000 0.0000 0.0001 0.0001 0.0003 0.0003

10° 0005 0006 0.0008 0.0010 0.0013 0.0015 0.0018 0.0022 0.0026 0.0031

20° 0.0036 0.0042 0.0048 0.0055 0.0062 0.0071 0.0079 0.0090 0.0100 0.0111

30° 0.0126 0.0136 0.0150 0.0165 0.0181 0.0197 0.0215 0.0234 0.0254 0.0276

40° 0.0298 0.0322 0.0347 0.0373 0.0400 0.0430 0.0461 0.0493 0.0527 0.0562

50° 0.0600 0.0637 0.0679 0.0721 0.0766 0.0812 0.0860 0.0911 0.0963 0.1018

60° 0.1075 0.1134 0.1196 0.1260 0.1327 0.1397 0.1469 0.1544 0.1622 0.1703

70° 0.1787 0.1874 0.1964 0.2058 0.2156 0.2257 0.2361 0.2470 0.2582 0.2699

80° 0.2819 0.2944 0.3074 0.3208 0.3347 0.3491 0.3640 0.3795 0.3955 0.4121

90° 0.4292—————————