5

TBVS4 User Manual

Rev.date: 20-09-2010

2 Installation

2.1 Points of attention

-The TBVS4 is suitable for gases and liquids.

Check the compatibility of the materials with the process fluid.

- Check if the connection is fitted far enough into the regulator and check for leakage across the

fitting.

- Avoid sealing compounds which harden, be careful with anaerobic (loctite type) compounds.

Particles of these compounds can run into the regulator and lock moving parts.

- Frequent assembly and disassembly of the in- and outlet fittings can damage the in- and outlet

thread of the regulator. Damaged threads can lead to galling.

2.2 Installation instructions

-Check the flow direction of the system and mount the TBVS4 in the right direction.

-The standard connection of the TBVS4 is ½" bspp female to ISO R/228/1.

-To get a proper seal SWAGELOK B.V. recommends the use of bonded seals.

-The regulator is to be mounted in the correct position – horizontally (= spring housing vertical).

-Check that the system pressure does not exceed the maximum allowed pressure of the regulator.

-Make sure the system is free of dirt.

-Check the flow direction.

-Turn set screw/knob fully counter clockwise.

3 Operation

-Slowly open the inlet valve.

-Crack the outlet valve open.

-Slowly turn setscrew clockwise until the inlet gauge in the system tells you that the set pressure

has been reached.

-Open outlet valve further.

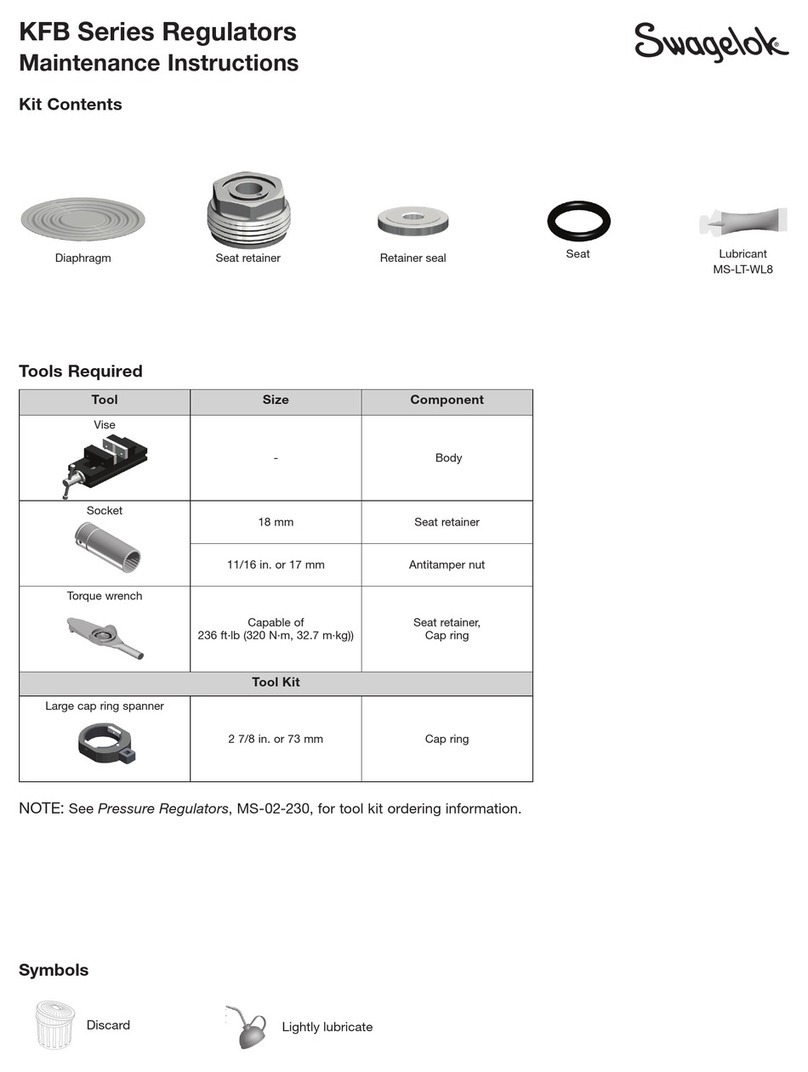

4 Maintenance

All regulators require maintenance at scheduled intervals.

Annual maintenance is recommended under normal use.

4.1 Points of attention

-Vent the system pressure before removing the regulator from the line.

-Maintenance should be done in a clean workshop, not with the regulator still installed.

4.2 Disassembly

- Put the TBVS4 into a vice. Make sure it is secure.

- Turn the adjustment screw counter clockwise to remove the spring load.

- Remove spring housing nbr. 2 by loosening the bolts nbr. 21, 22 and 23.

- Remove the upper spring guide and spring housing.

- Loosen nut 20 and remove diaphragm plate 16.

- Loosen clamp ring nbr. 15.

- Screw the seat retainer nbr. 7 out, valve assembly and seat can now be removed.

Replace damaged parts and assemble in reversed manner.

4.3 Testing

It is recommended to test the repaired/maintained regulator in a test bench before re-installation in the

system.

Warranty Information

Swagelok products are backed by The Swagelok Limited Lifetime Warranty.

For a copy, visit swagelok.com or contact your authorized Swagelok representative.