Swagelok KCP Series Technical specifications

Other Swagelok Controllers manuals

Swagelok

Swagelok TBVS4 User manual

Swagelok

Swagelok TBVS8 User manual

Swagelok

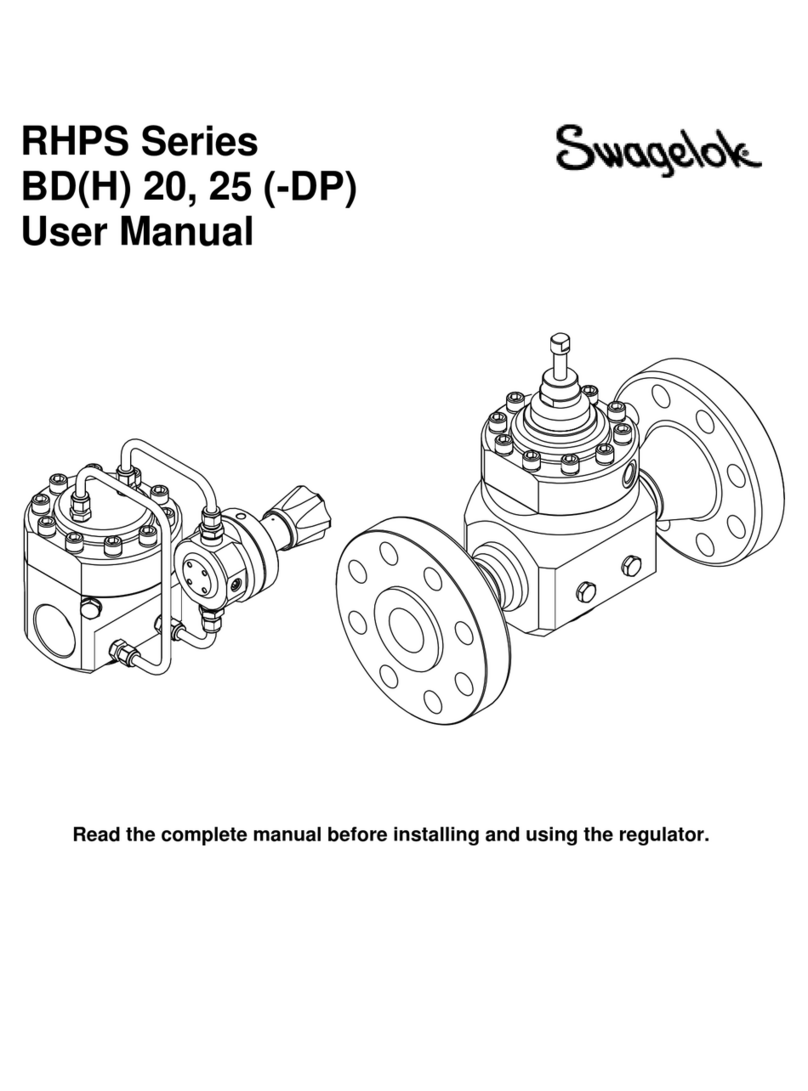

Swagelok RHPS Series User manual

Swagelok

Swagelok RHPS Series User manual

Swagelok

Swagelok RS20 User manual

Swagelok

Swagelok RHPS Series User manual

Swagelok

Swagelok RS10 Series User manual

Swagelok

Swagelok KLF Series User manual

Swagelok

Swagelok BS20 User manual

Swagelok

Swagelok PRS15 User manual

Swagelok

Swagelok RHPS Series User manual

Swagelok

Swagelok KPR Series Technical specifications

Swagelok

Swagelok RHPS Series User manual

Swagelok

Swagelok KHB Series Technical specifications

Swagelok

Swagelok RHPS Series User manual

Swagelok

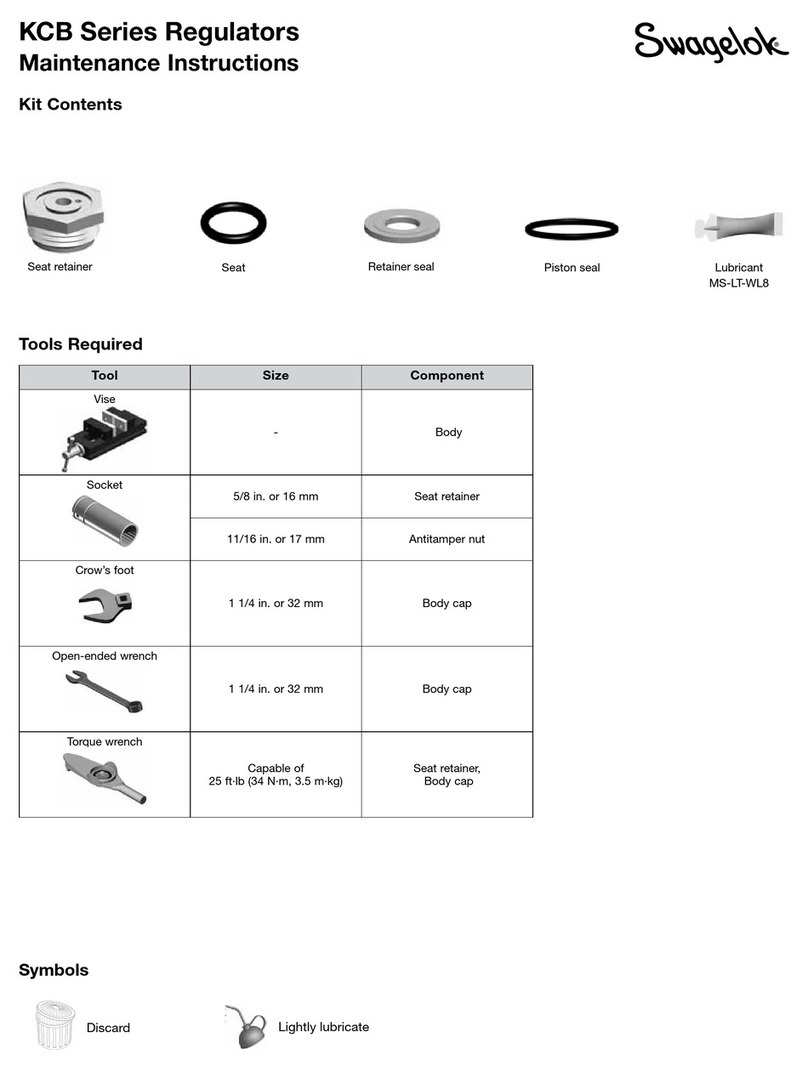

Swagelok KCB Series Technical specifications

Swagelok

Swagelok PRS4 User manual

Swagelok

Swagelok RHPS Series User manual

Swagelok

Swagelok LBS4 User manual

Swagelok

Swagelok RS2 User manual