M100 Power Supply

2 ©1999 Swagelok Company, all rights reserved

August 2001

Installation

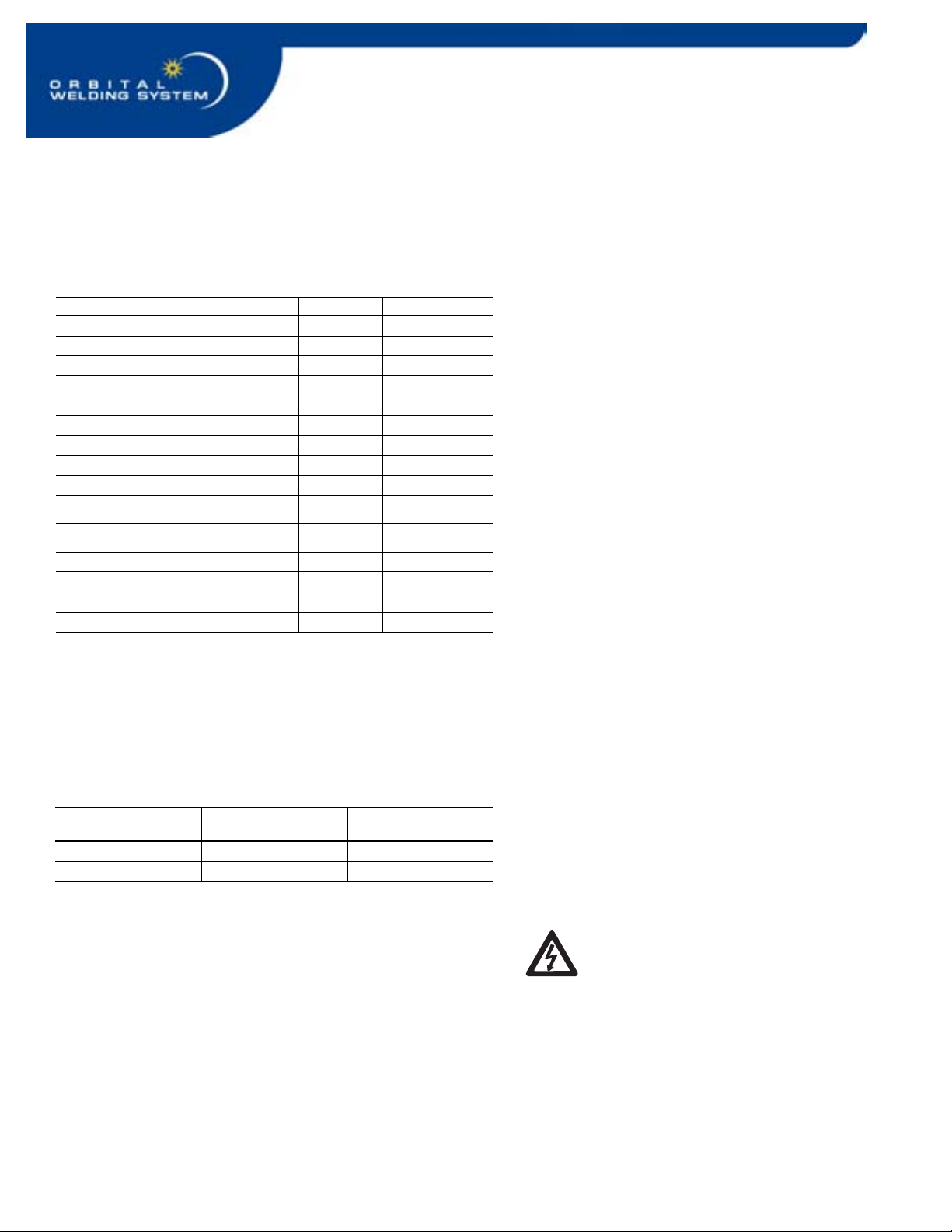

Tools and Accessory Requirements

You need the following tools and accessories to install

and operate your SWS.

Tool/Accessory Included? Provided with

Hex Wrenches (0.050 in. to 5/32 in.) Yes Weld Head

Electrode Package Yes Weld Head

Arc Gap Gage Yes Weld Head

Flat Blade Screw Driver Yes Weld Head

Centering Gage Yes Fixture Block

Quick-Connect Stem Yes Power Supply

Secondary Solenoid Bypass Plug Yes Power Supply

Dial/Digital Calipers or Micrometer No -

Purge Connector(s) No -

Shielding/Purge Gas Lines ①No -

Shielding/Purge gas Source②No -

Pressure Regulator No -

Internal Purge Gas Flow Meter No -

Shielding Gas Flow Meter No -

Internal Pressure Gage No -

①All lines used for shielding/purge gas should be the low moisture

absorption type.

②A compressed gas bottle or liquid Dewar source can be used. Argon

is the gas most frequently used.

Note:

The Series 40 weld head does not

include an arc gap gage, centering

gage, or electrode package.

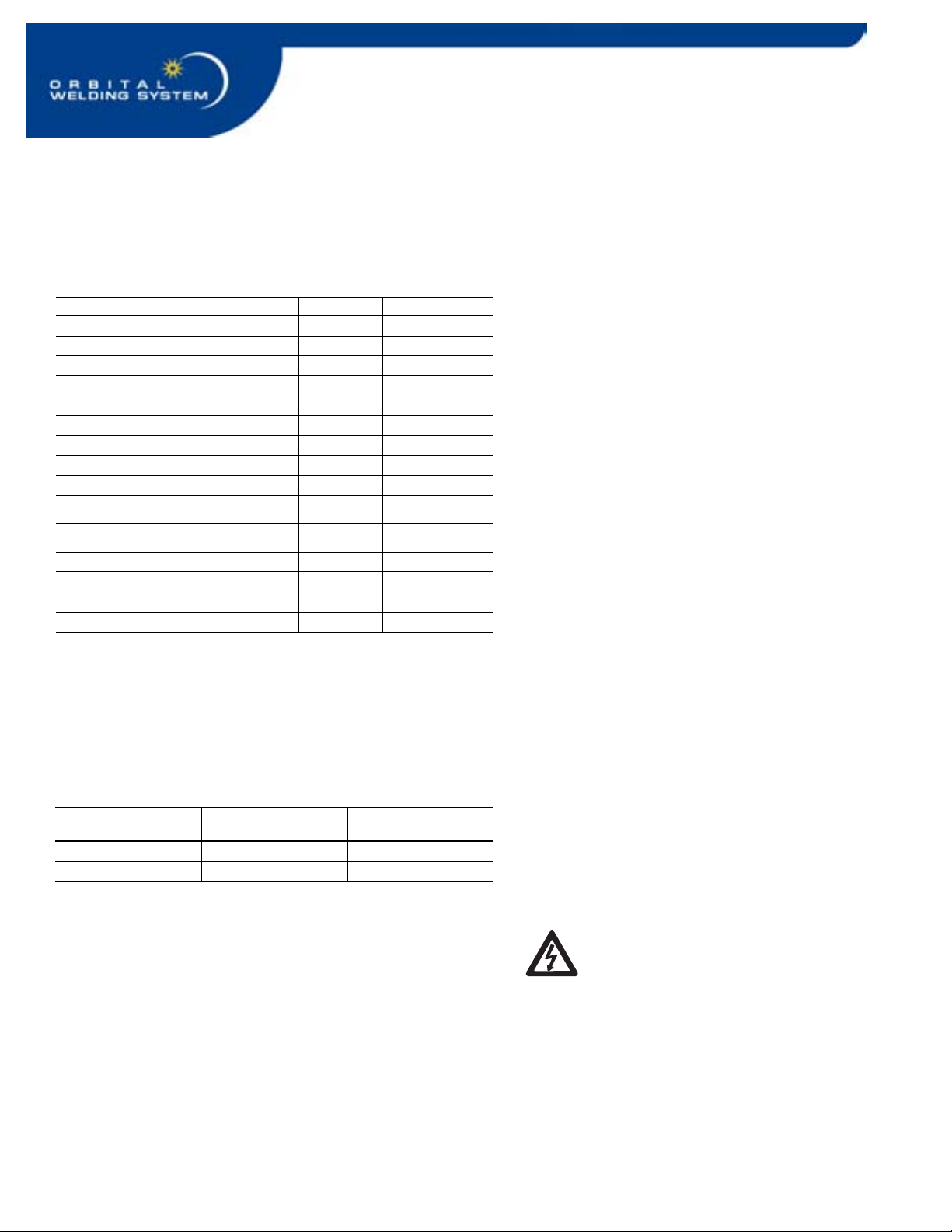

Electrical Requirements

Table 1 Power Supply Electrical Requirements

Power Supply

Model

Voltage

Requirement

Service Current

SWS-M100-1 115 V*(ac) 20 A

SWS-M100-2 230 V (ac) 15 A

* If the input voltage is 100 V or less, the output power capabilities

may be reduced.

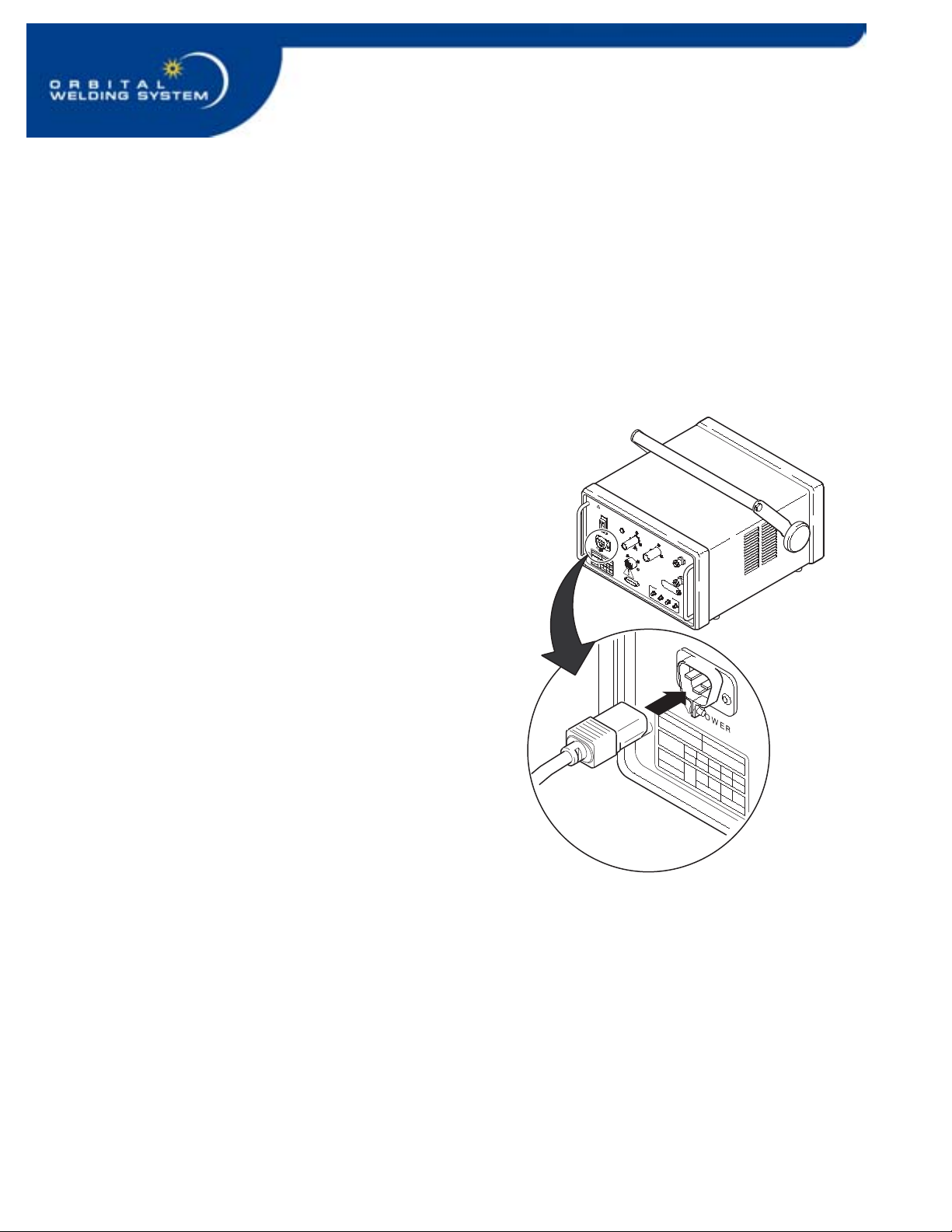

Follow the electrical system guidelines below for power

supply installation.

• All wiring and related components must be

installed according to local code and National

Electrical Code.

• The power supply must be grounded.

• A dedicated electrical circuit may be desired due

to current need.

WARNING!

THE POWER SUPPLY MUST

BE GROUNDED. IF IT IS NOT

GROUNDED, ELECTRICAL

SHOCK CAN OCCUR.