Herzog HP Installation and maintenance instructions

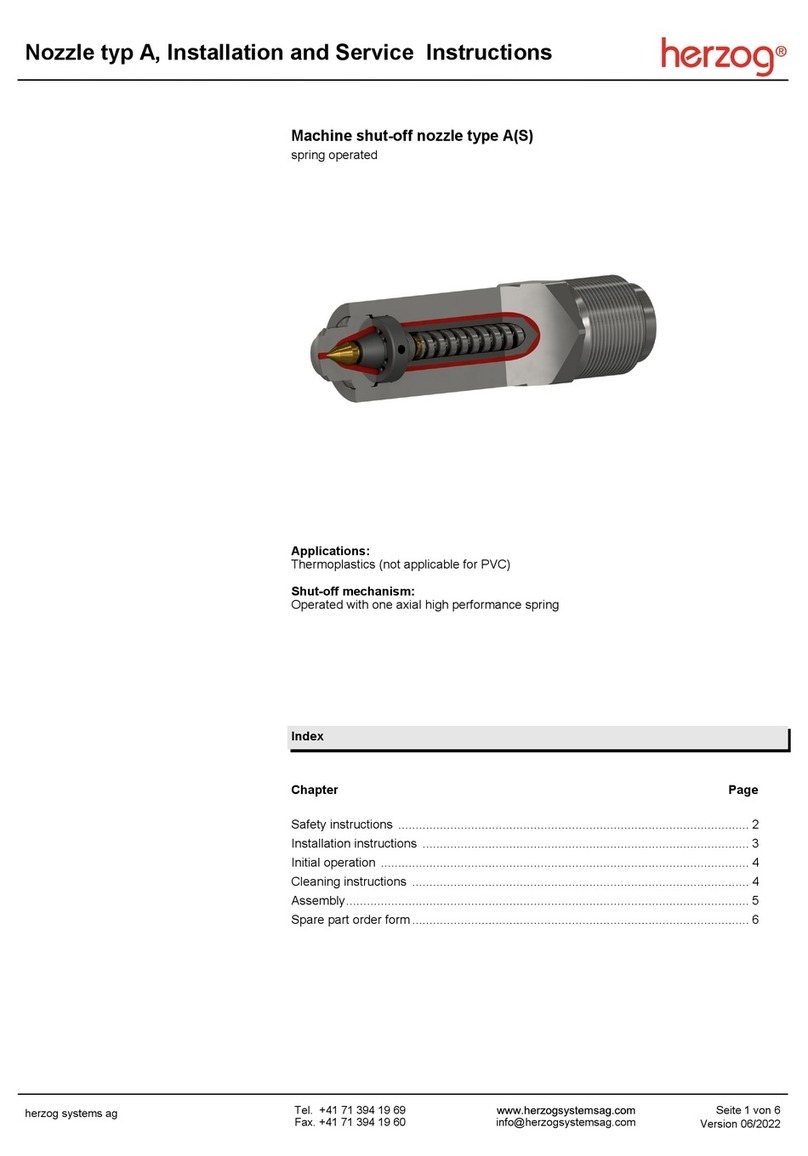

HP-Nozzle, Installation & Service Instructions

herzog systems ag Tel. +41 71 394 19 69

Fax. +41 71 394 19 60

info@herzogsystemsag.com Seite 1 on 10

Version 06/2022

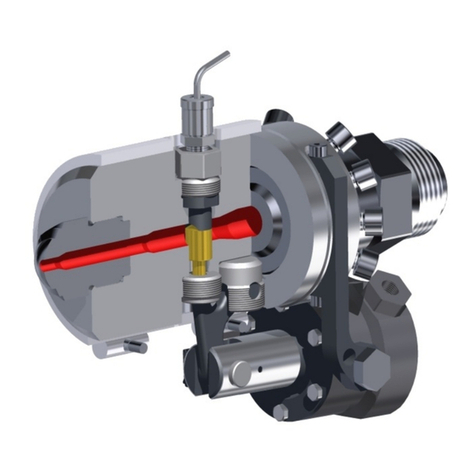

Machine needle shut-off nozzle type HP

pneumatically or hydraulically controlled

Chapter Page

Safety instructions ...................................................................................................... 2

Installation instructions ............................................................................................... 3

- Installation steps ................................................................................................. 3

Initial operation ........................................................................................................... 6

Ideal nozzle actuation stages ..................................................................................... 6

Ser ice instructions .................................................................................................... 7

- Disassembly ....................................................................................................... 7

- Recommended disassembly tool ........................................................................ 8

- Cleaning instructions ........................................................................................... 8

Assembly .................................................................................................................... 9

Parts subject to wear / ordering spare parts ............................................................... 10

Index of contents

HP-Nozzle, Installation & Service Instructions

herzog systems ag Tel. +41 71 394 19 69

Fax. +41 71 394 19 60

info@herzogsystemsag.com Seite 2 on 10

Version 06/2022

Please pay attention to the follo ing safety instructions and precautions

Safety instructions

This symbol indicates explanations about important matters.

Failure to read these or false handling could result in injury or damage.

Handling

Installation and ser icing to be only carried out by suitable personnel according to

the installation and ser ice instructions.

Nozzle can become extremely hot. Full face protection and heat resistant glo es

must be worn.

Damage precaution

Nozzle is only to be used for injection molding purposes.

Torques on screws and threaded parts must be adhered to.

Maximum injection rate / temperature: 3000 bar at 400°C.

Shut-off operation according to Melt pressure / time graph.

Ne er heat steel parts o er 520°C.

The actuator is designed for temperatures up to 180°C.

No adjustment or manipulation when nozzle is in operation.

Take care that no foreign bodies enter the working parts of the nozzle.

Do not drop the nozzle or exert it to unnecessary forces.

Noise emissions from the nozzle do not exceed 70 dB(A).

Explosion danger

Some plastics produce gases if they stay for a longer time in a heated en ironment.

There is a risk that the gas may escape explosi ely through the nozzle orifice.

Keep this manual in a convenient place for future reference.

HP-Nozzle, Installation & Service Instructions

herzog systems ag Tel. +41 71 394 19 69

Fax. +41 71 394 19 60

info@herzogsystemsag.com Seite 3 on 10

Version 06/2022

B)

A)

1. Loosen and respecti ely remo e heater band screws

2. Take off heater band

Installation instructions

2.

1.

1. Loosen screws

2. Loosen tip

3. Screw the adapter out

1.

3.

Note: Loosen the screws by four rotations.

4 x 360°

Legend:

with Hand inspection

smear with high temperature lubricant temperature equalisation

tool

Read safety instructions!

Note:

Nozzle is deli ered pre-assembled. The following instructions are for installation on the

machine. For easier handling remo e the actuator.

Tools required:

Hexagonal wrench, allen key, ring spanner, socket wrench, pliers, punch.

See chapter Assembly for tool sizes and torques.

Installation steps A) - G)

2.

HP-Nozzle, Installation & Service Instructions

herzog systems ag Tel. +41 71 394 19 69

Fax. +41 71 394 19 60

info@herzogsystemsag.com Seite 4 on 10

Version 06/2022

C)

3.

1. 2.

1. Check surfaces and threads

2. Smear adapter thread with high temperature lubricant

3. Mount adapter; await temperature equalisation and tighten acc.

to machine handbook

4.

4. Tighten two screws crosswise

crosswise

D)

1. Screw nozzle onto the adapter until contact

2. Screw in tip further until contact

3. Loosen the two pre iously tightened screws by four rotations.

4. Screw in tip approx. 180° further

3.

1.

5. Align: Screw nozzle clock ise further onto the machine

Note: min. ¼ rotation

5.

Align nozzle

Rotate clockwise

E)

1. Tighten two crosswise screws

2. Check gap between body and adapter ring max. 2.5 mm

1.

2.

ll = min. 0.5 mm to max. 2.5 mm ll = min. 0 mm to max. 1 mm

Adapter ring gap nonexistent: Loosen the two screws

and screw the nozzle 360° clockwise.

2. + 4.

tip ring adapter ring

HP-Nozzle, Installation & Service Instructions

herzog systems ag Tel. +41 71 394 19 69

Fax. +41 71 394 19 60

info@herzogsystemsag.com Seite 5 on 10

Version 06/2022

F)

Torque HP0 HP1 HP2

1. pass handtight handtight handtight

2. pass 7 Nm 15 Nm 35 Nm

3. pass 10 Nm 22 Nm 45 Nm

4. pass 12 Nm 25 Nm 50 Nm

1. Tighten all screws in a crosswise fashion crosswise

1.

1. Mount heater band (1a) and temperature sensor (1b)

2. Attach flexible actuator pipe connections

Note: The actuator can be rotated 180° to suit

3. Tighten tip ith torque according to chapter Assembly*

* Tip is already tight when mounting step E) has been correctly obser ed and the

required gap exists between tip-ring and the nozzle body

G) 1b.

1a.

3.

2.

HP-Nozzle, Installation & Service Instructions

herzog systems ag Tel. +41 71 394 19 69

Fax. +41 71 394 19 60

info@herzogsystemsag.com Seite 6 on 10

Version 06/2022

When machine is powered off or idle for a long period:

Purge processed material from nozzle

Open nozzle

Reduce nozzle temperature

Initial operation

Leakage release area

approx. 1cm3 per day

Read safety instructions!

1. Bring nozzle to operating temperature

2. Only for first operation: tighten 8 body screws and heater band screws to maximum

recommended torques

3. Make sure that polymer is completely melted

4. Purge heated melt. This follows after extrusion at low speed (time ca. 25 - 30s) or

through injecting out at three to fi e times injection time

Actuator: Operational data according to engra ing on cylinder.

Leakage: Between needle and guide there is a melt film which pre ents the needle from

blocking. The melt film will be continuously renewed and will e entually leak out of the

nozzle in the area indicated beside.

This melt release is completely normal, especially when low iscosity material is

combined with high back pressure. The material will not affect the function of the

nozzle as the actuator piston stroke and le er mo ement respecti ely keeps the area

clear. If required any gathered residual material can be manually cleaned away.

While injecting no leakage should emit in this area and the nozzle is completely sealed.

Machine do ntime

Actuating nozzle at stages indicated in the graph helps increase longe ity of wear parts.

Melt pressure / time graph:

Nozzle actuation stages

Nozzle open Nozzle closed

Time

Back pressure

Injection

pressure

Actuate nozzle open Actuate nozzle close

Melt pressure

Dosing start

Injection start

Holding pressure

Ideally at 10 to 50bar

melt pressure

Ideally when pressure

is lowest

HP-Nozzle, Installation & Service Instructions

herzog systems ag Tel. +41 71 394 19 69

Fax. +41 71 394 19 60

info@herzogsystemsag.com Seite 7 on 10

Version 06/2022

Service instructions

Read safety and cleaning instructions!

Assembly Note: Grease all threads ith high temperature paste!

4.

2.

5.

A)

Disassembly A) - B)

3.

360° x 2

1.

Removing the nozzle from the machine:

1. Heat nozzle to operating temperature

2. Remo e actuator (Actuator ser ice information a ailable seperately in documentation

Actuator. See www.herzog-ag.com)

3. Remo e temperature sensor

4. Remo e heater band

5. Loosen screws (t o rotations)

B)

1a. 1b.

2.* 3a. 3b. 4a. 4b.

1. Remo e tip (1a.), Needle (1b.) and holding pin (1c.)

2. Remo e bushing. *If you ha e difficulty remo ing the bushing we recommend using

our disassembly tool, see Recommended disassembly tool

3. Remo e screws (3a.) and nozzle body (3b.)

4. Remo e bracket (4a.) and adapter (4b.)

5. Strike out the le er bolt using a punch (5a.) and remo e le er (5b.)

1c. 5b. 5a.

HP-Nozzle, Installation & Service Instructions

herzog systems ag Tel. +41 71 394 19 69

Fax. +41 71 394 19 60

info@herzogsystemsag.com Seite 8 on 10

Version 06/2022

Recommended disassembly tool

Option:

Our disassembly tool eases the needle bushing remo al.

1. Holding pin must be remo ed or min. 5 mm screwed out

2. Position remo al nut

3. Screw in remo al screw until the bushing is remo ed

Assembly Note:

Bushing bore must be aligned with holding pin. Tighten the holding pin with moderate

strenght (ca. 8Nm).

The end position of the holding pin is approx. 0.5

mm away from the body unit.

More information at www.herzog-ag.com

2.

3.

lubricate

1.

While the nozzle is still installed, clean as far as possible in a heated state and finally

disassemble completely and clean indi idual parts.

Plastics such as; LCP or PPS burn away when the nozzle is heated in an o en for tow

hours at 500°C.

Ne er heat steel parts abo e 500°C!

Clean pneumatic or hydraulic actuator separately with max. 150°C!

A oid kinking the heater band and sensor cables!

Help tools for cleaning:

Sand fluidized bed

Glass bead blasting

Cleaning o en

Gas burner

Wire brush

Steel wool

Before reassembly: check all parts for damage or wear.

Profit from our cleaning ser ice. The nozzle is disassembled, checked and repaired if

necessary after customer appro al.

Cleaning instructions

HP-Nozzle, Installation & Service Instructions

herzog systems ag Tel. +41 71 394 19 69

Fax. +41 71 394 19 60

info@herzogsystemsag.com Seite 9 on 10

Version 06/2022

Assemble according to the numerical order.

Assembly

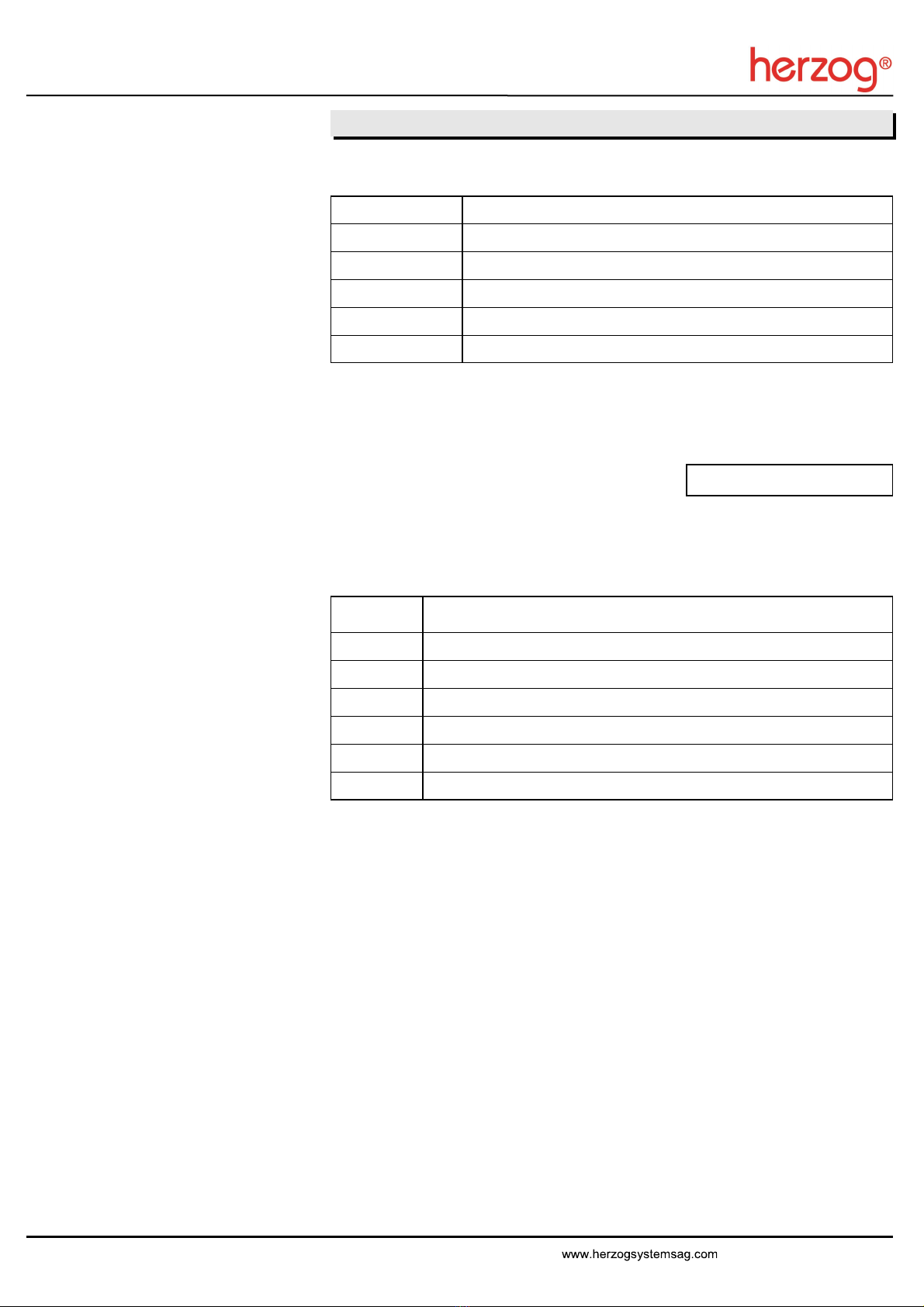

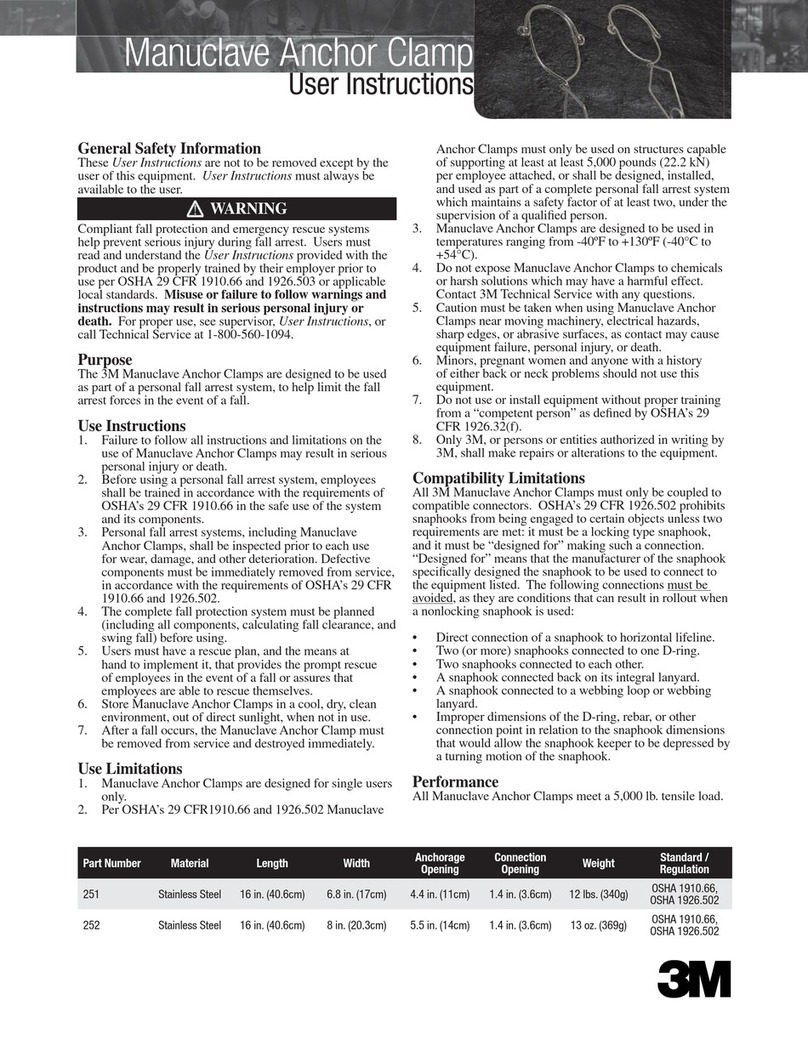

Pos. Qty. Description Tool size (Torque)

HP0 HP1

Metric (Nm) Imperial (lbs/ft) Metric (Nm) Imperial (lbs/ft) Metric (Nm) Imperial (lbs/ft)

1 1 Body - - - - - -

2 1 Needle bushing - - - - - -

3 1 Holding pin SW5 (3) 3/16 (2.2) SW5 (3) 3/16 (2.2) SW8 (5) 5/16 (3.7)

4 1 Le er - - - - - -

5 1 Pi ot bolt - - - - - -

6 12 Screws SW5 (12) 3/16 (8.8) SW6 (25) 1/4 (18.4) SW10 (50) 13/32 (3 .8)

7 1 Bracket / Adapter ring - - - - - -

8 1 Adapter (torque acc. to

machine handbook) SW36 1 7/16 SW46 - 60 1 13/16 - 2 3/8 SW65 - 80 2 6/16 - 3 1/8

9 1 Needle - - - - - -

10 1 Tip SW27 (220) 1 1/16 (1 2) SW36 (500) 1 7/16 (3 8) SW55 (1200) 2 3/16 (885)

10.1 1 Base for two-piece tip SW36 (220) 1 7/16 (220) SW41 (500) 1 5/8 (3 8) SW65 (1200) 2 9/16 (885)

10.2 1 Cap for two-piece tip SW27 (120) 1 1/16 (88.5) SW32 (200) 1 1/4 (147) SW41 ( 00) 1 5/8 (442)

11 1 Actuator - - - - - -

12 2 Bolt screws SW13 (12) 1/2 (8.8) SW17 (30) 11/16 (22.1) SW17 (30) 11/16 (22.1)

13 1 Bolt - - - - - -

14 1 Splint - - - - - -

15 1 Heater band - - - - - -

16 2 Heater band screws SW4 5/32 SW4 5/32 SW4 5/32

17 1 Temperature sensor SW14 9/16 SW14 9/16 SW14 9/16

HP2

Note: Grease all threads with high temperature paste! See also chapter: Disassembly.

HP-Nozzle, Installation & Service Instructions

herzog systems ag Tel. +41 71 394 19 69

Fax. +41 71 394 19 60

info@herzogsystemsag.com Seite 10 on 10

Version 06/2022

Parts subject to ear / ordering spare parts

Your contact information:

Company

Street

City / Zip

Contact

Tel. / Fax

E-Mail

Lasered nozzle identity no.: please insert here

Quantity Part (for part name, see chapter Assembly)

Send to:

herzog systems ag

CH-9230 Flawil / Switzerland

Tel. +41 71 394 19 69 / Fax +41 71 394 19 60

www.herzog-ag.com / [email protected]

Table of contents

Other Herzog Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

ABB

ABB HT608117 Operation manual

Hydac

Hydac RFX Installation and maintenance instructions

UnionSpecial

UnionSpecial BC200 ORIGINAL INSTRUCTIONS ENGINEERS, AND ILLUSTRATED PARTS MANUAL

SLC

SLC SLC-LF 18 CD General assembly instructions

3M

3M 251 User instructions

Stober

Stober RB 5022 Commissioning instructions