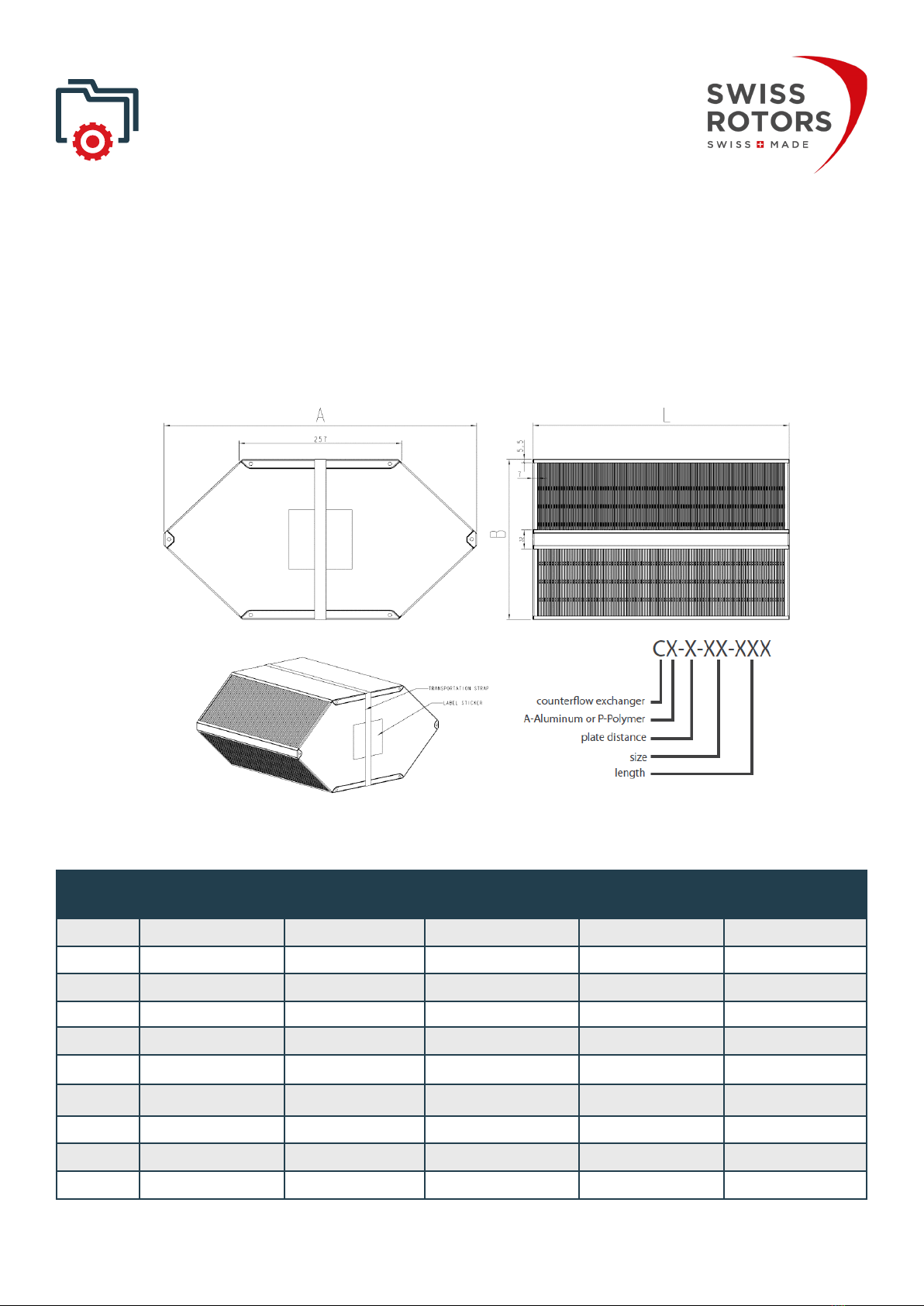

6

3. TRANSPORTATION

3.1 Packing

To avoid dents or scratches on the exchange surface please make sure to properly secure the package for the

transportation.

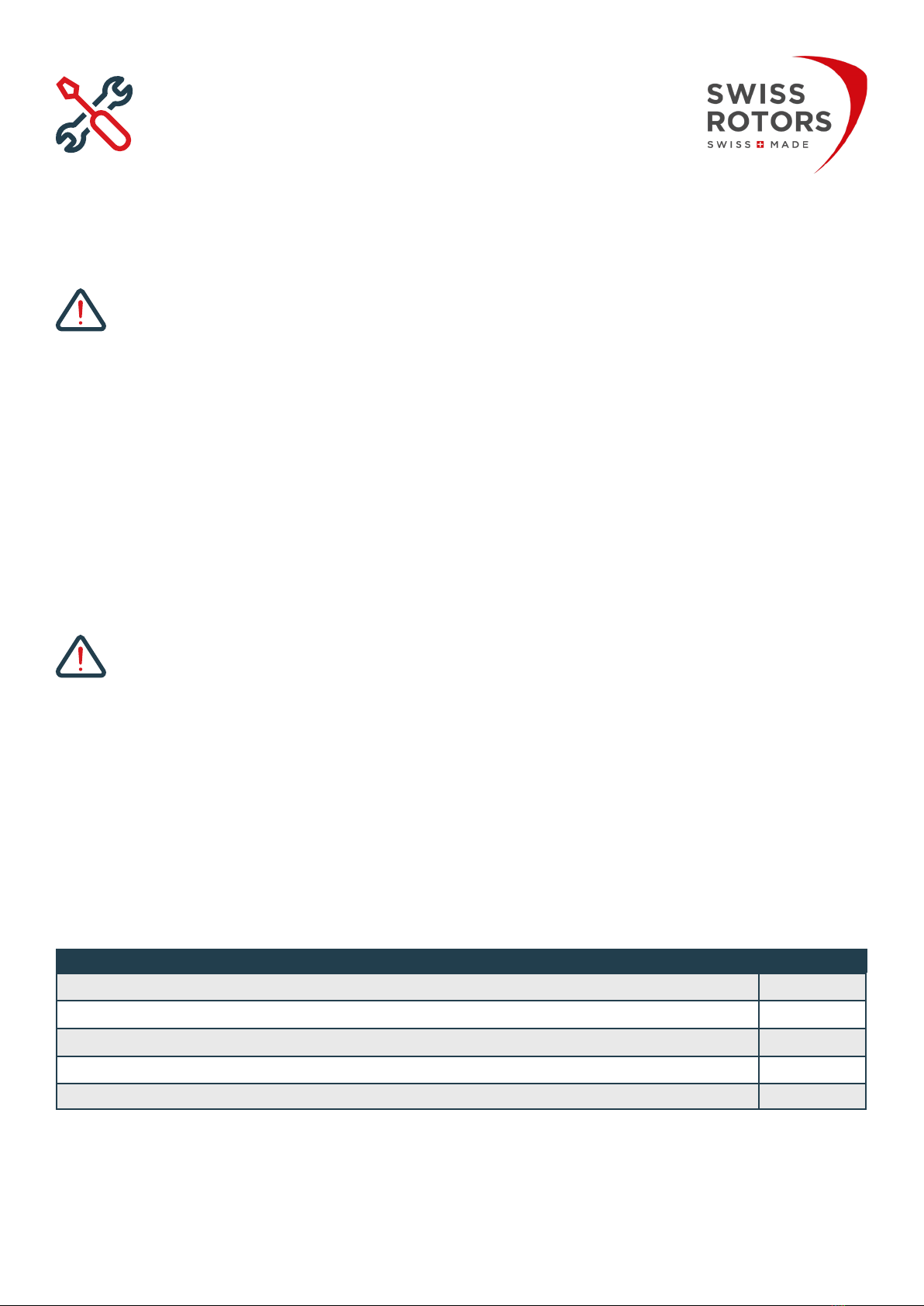

Counterow heat exchangers are packed in a stretch wrapped pallets. The

exchangers are interleaved with a cardboard with appropriate incisions and

clutched with the belt and have corners secured with a cardboard as shown on

a picture below (Fig.3). Be extra carefull while handling the heat exchangers –

construction elements may have sharp edges – use protective gloves to avoid

injuries.

3.2 Quality control

3.2.1 Examine the package:

1. Check the conditions of the package carefully in the presence of a

shipping company representative before delivered parcel will be accepted. Look

for any signs of transportation damage. Our counterow heat exchangers are

precisely and tightly secured for the shipment. There should not be any signs of

tearing on the surface of the package, punctures, exposed elements or traces

of opening.

2. Pay attention to the way in which the goods were delivered. – Fig.3.

3. Swiss Rotors prepares shipments using professional labels and

transport descriptions. If you see that the shipping company did not follow the

instructions - refuse to accept the parcel.

4. Check if the received parcel matches with your order. Inspect the product identication plates for conrmation.

5. In case of noticing any damage please contact our support immediately – phone numbers are listed at the

Support chapter of this guidebook or at our ocial website: www.swissrotors.com

3.2.2 Examine the unit

1. Remove packing materials from the product.

2. Dispose of all packing materials in accordance with local regulations.

3. To determine whether any parts have been damaged or are missing, examine the product carefully.

4. If there is any issue, please contact our support.

3.3 Storage

If the exchanger is not installed immediately, leave the product in its original packaging and follow the rules of

proper storage.

Prolonged exposure of the product to the improper conditions may damage and shorten the lifetime of the heat ex-

changer.

• Avoid exposure to moisture, excessive sunlight (especially unfavorable for polymer exchangers) and other

weather conditions.

• Make sure the counterow heat exchanger is positioned vertically on the dry and at ground.

• Support and secure the exchanger against mechanical damages, do not stack.

• Keep the storage temperature between 0°C and 40°C for aluminum exchangers and 5°C and 25°C

Figure 3. Packing model