TABLE OF CONTENTS

SafetyInstructions ......................................................................... 4

1) Information ........................................................................... 4

2) AboutUltraviolet(UV)Disinfection ........................................................ 4

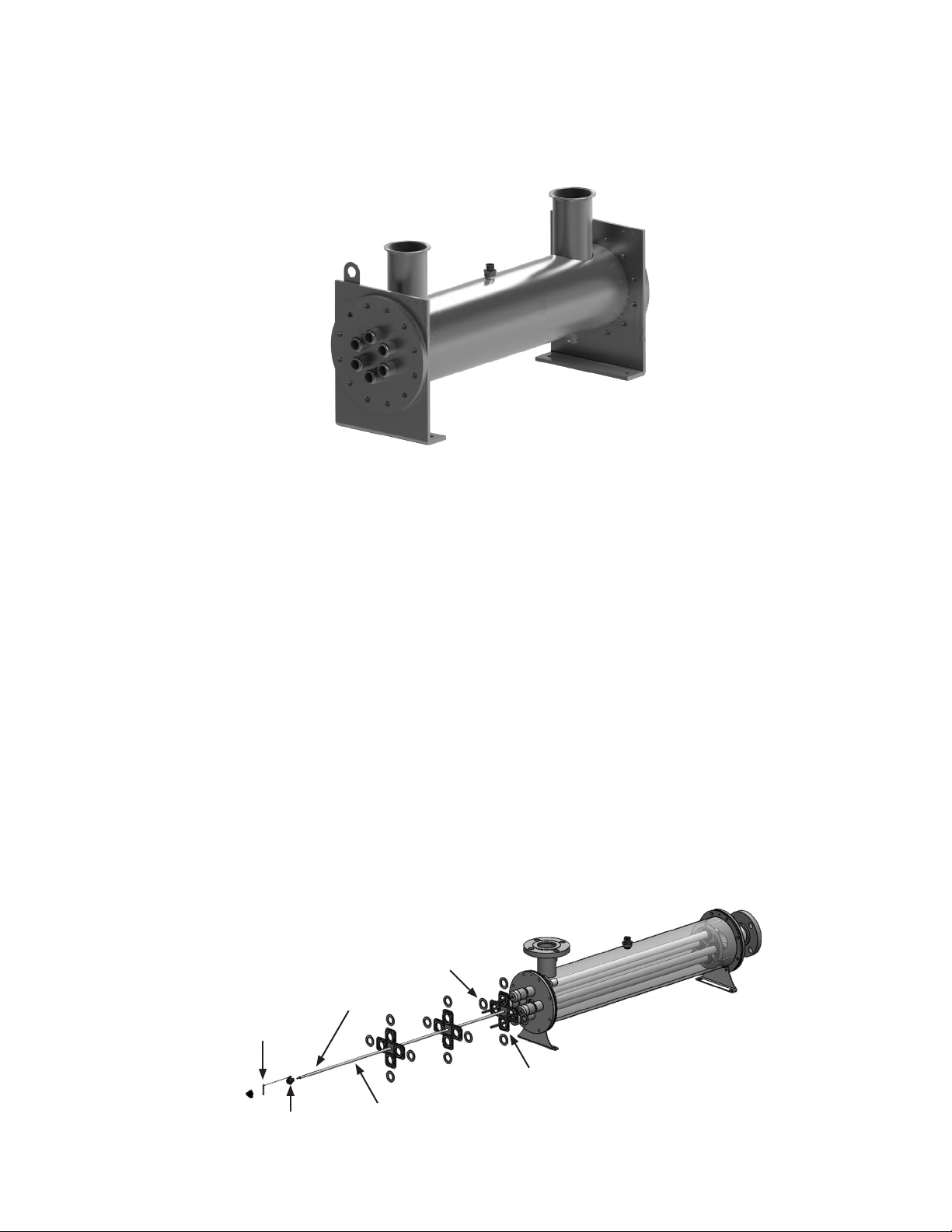

3) MajorComponents .................................................................... 5

a) DisinfectionChamber ............................................................... 5

b) LampsandQuartzSleeves ........................................................... 5

c) ManualQuartzSleeveWiperSystem................................................... 5

d) ElectronicControlCenter(ECC) ...................................................... 6

4) PreparationForInstallingUVSystem ...................................................... 8

a) WaterQuality ...................................................................... 8

b) ImportantSafetyInformation ......................................................... 8

c) OptimizingSystemPerformance ...................................................... 9

d) EnvironmentalIssuesRelatingtoUVLamps ............................................. 9

e) ReceivingUVEquipmentandSpareParts .............................................. 9

f) Electrical Configuration and Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5) Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

a) ElectronicControlCenter(ECC) ..................................................... 10

b) HandsOffAutoSwitchWiring ........................................................ 11

c) LampOutAlert(Optional) .......................................................... 12

d) Chamber......................................................................... 12

e) SensorProbeInstallation ............................................................ 12

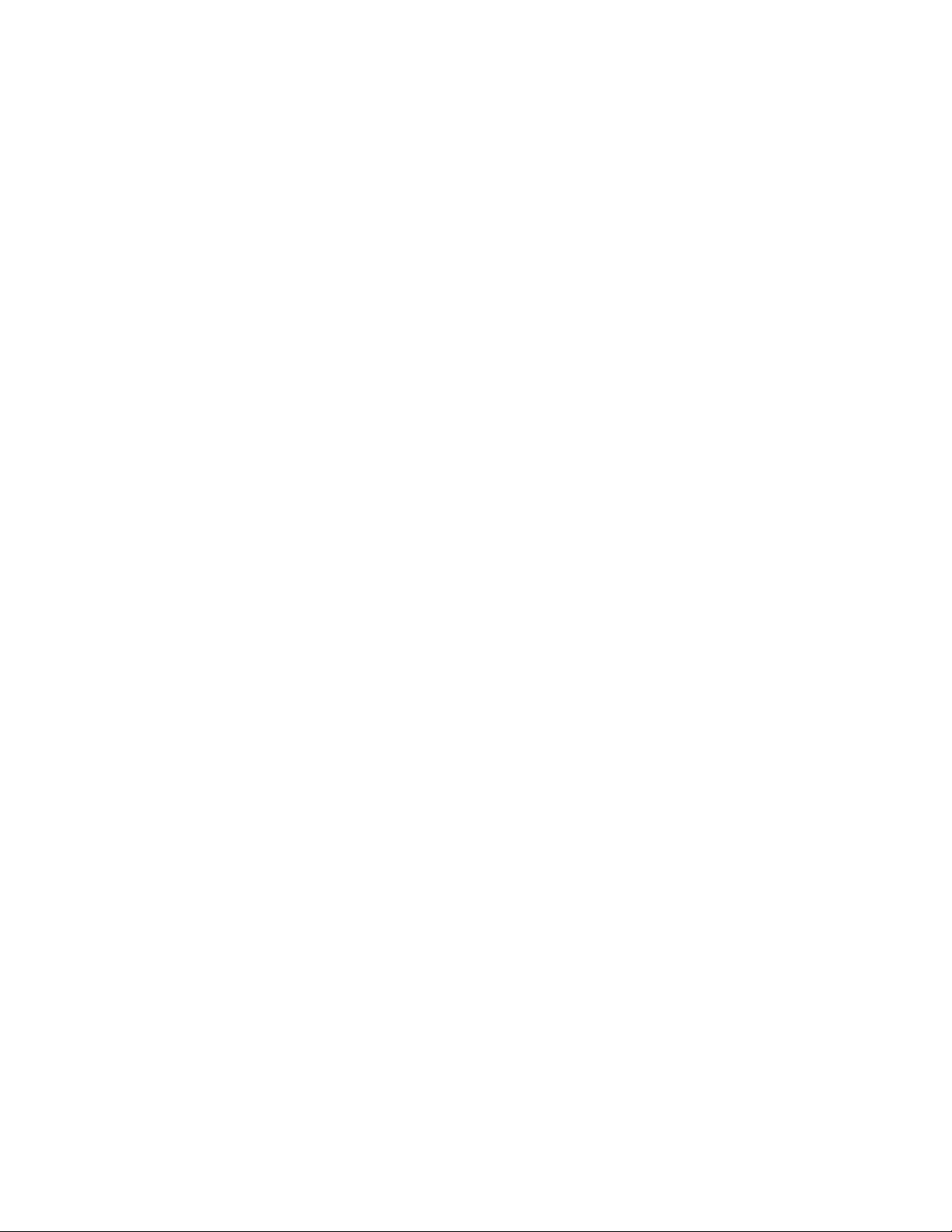

f) Quartz Sleeve Installation for Open Ended Sleeves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

g) Lamp and Lamp Harness Bracket Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6) Electronic Control Center (ECC) Operation and Moinitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

a) On/OffSwitch ..................................................................... 16

b) LampStatus....................................................................... 16

c) RuntimeMonitoring ................................................................ 17

d) Viewport ......................................................................... 17

e) ManualQuartzSleeveWiperSystem.................................................. 17

f) LampOutAlert(Optional) .......................................................... 17

g) StandardUVMonitor(Optional) ..................................................... 18

h) StandardHighHeatSensor(Optional) ................................................ 20