Page 7 of 9 9/19/2012

5.2 Ring Panel Filter Replacement:

5.2.1 Turn the SYCLONE unit off and make sure to disconnect the power supply cord from

the unit.

5.2.2 Open the door and remove the contaminated ring panel filter.

5.2.3 Fold in the sides of the contaminated filter and dispose of as per section 5.4.

5.2.4 Install a new ring panel filter making sure to place it against the HEPA filter. This will

position the filter properly.

5.2.5 Close door and fasten the draw latch.

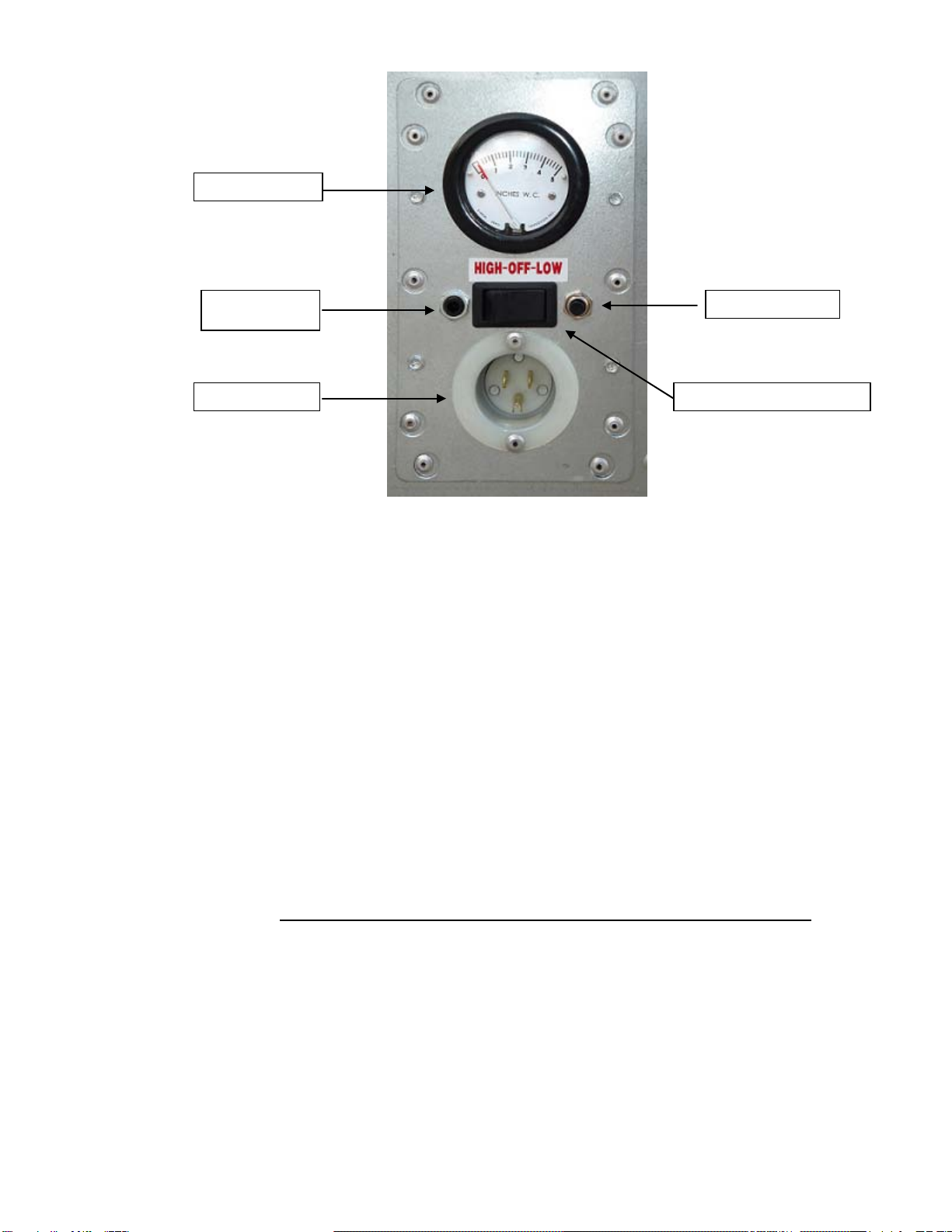

5.2.6 Reconnect the power supply cord, then turn the unit on, and check the pressure

gauge at the control panel.

5.2.7 If the pressure still exceeds the pressure stated above, the HEPA filter also needs to

be replaced.

5.3 HEPA Filter Replacement:

5.3.1 Turn the SYCLONE off and make sure to disconnect the power supply cord from the

unit.

5.3.2 Open the door and remove the ring panel filters, as described in section 5.2.

5.3.3 Remove the HEPA filter by loosening the four nuts and rotating the tabs to the open

position.

5.3.4 Pull the HEPA filter out of the cabinet and dispose of as per section 5.4.

5.3.5 Inspect the gasket on the new HEPA filter housing before installation, to make sure

there are no gaps, cracks, or defects. Any defects in the gasket will allow leakage of

contaminated air through the unit.

5.3.6 Place the new HEPA filter in the unit with the gasket end facing the fan. Check to see

that the filter lies squarely on the base bracket.

5.3.7 Push the HEPA filter against the HEPA flange bulkhead and rotate the looking tabs

to the closed position.

5.3.8 Tighten the HEPA filter hold-down nuts securely to prevent air leaks.

5.3.9 Install ring panel filter as described in section 5.2.

5.3.10 Close door and fasten the draw latch.

-THE NEW HEPA FILTER NEEDS TO BE THE SAME SIZE AND TYPE, AS THE ONE BEING

REPLACED.

- WHEN THE HEPA FILTER IS REPLACED, THE PRE-FILTER PAD AND RING PANEL FILTER

SHOULD ALSO BE REPLACED. THIS WILL HELP TO EXTEND THE LIFE OF THE HEPA FILTER