⚠ATTENTION ⚠

PERSONNEL RESPONSIBLE FOR CHANGING FILTERS,

SERVICING, OR RELOCATING THE UNIT MUST WEAR

APPROVED RESPIRATORS AND PROTECTIVE EQUIPMENT. THE

REPLACEMENT FILTERS MUST BE THE SAME SIZE/TYPE AS THE

ONE BEING REPLACED. WHEN THE HEPA FILTER IS

REPLACED,THE PRE-FILTER PAD AND RING PANEL FILTER

SHOULD ALSO BE REPLACED. THIS WILL HELP TO EXTEND THE

LIFE OF THE HEPA FILTER.

•Turn the SYCLONE unit off and make sure to

disconnect the power supply cord from the machine.

•Watch for sharp edges, lift the door up and out of the

channel. Remove the contaminated pre-filter pad,

folding in the sides, and dispose of the filter

properly.*

•Next, carefully remove the contaminated ring panel

filter. Fold in half before proper disposal.*

•To remove the HEPA filter, loosen the four nuts and

rotate the four tabs to the open position. Carefully,

pull the HEPA filter out of the cabinet and dispose. To

prevent contamination, wipe down all exposed

surfaces and clean machine thoroughly BEFORE

installing new filters.

•Inspect the gasket on the new HEPA filter housing

before installation, to make sure there are no gaps,

cracks, or defects. Any defects in the gasket will allow

leakage of contaminated air through the unit.

•Place the new HEPA filter in the unit with the gasket

end facing the fan. Check to see that the filter lies

squarely on the base bracket.

•Push the HEPA filter against the HEPA flange

bulkhead. Rotate the locking tabs to the closed

position; tighten the nuts to ensure the HEPA tabs are

secure. Install the ring panel filter and pre-filter pad.

Place the door back into the channel, slowly

dropping the door closed.

•Reconnect the power supply cord. Then turn the unit

on and check the pressure gauge at the control

panel.

*USED FILTERS ARE CONSIDERED CONTAMINATED WASTE AND MUST BE

DISPOSED IN COMPLIANCE WITH ALLAPPLICABLE REGULATIONS.

FIRST STAGE — PRE-FILTER PAD

•24” x 24” x 1” — 1-Ply Pad

•Removes large particles up to 10 microns

and larger from the air flowing through the

unit, thereby preventing premature loading

of the second stage and HEPA filters. The

pre-filter pad is recommended to be

changed as it becomes loaded and the

airflow capacity of the unit decreases—or the

pressure gauge at the control panel exceeds

2.6 inches at high speed or 1.9 inches at low

speed, of W.C.

SECOND STAGE — RING PANEL

•24” x 24” x 1” — 2-Ply Ring Panel

•Removes particles up to 1 micron and larger

from the air flowing through the unit, thereby

protecting the more expensive, HEPA filter.

The ring panel filter is recommended to be

changed as it becomes loaded and the

airflow capacity of the unit decreases—or the

pressure gauge at the control panel exceeds

2.6 inches on high speed (1.9 inches on low

speed) of W.C..

THIRD STAGE — HEPA

•24” x 24” x 11.5” (99.97%) Wood Frame

HEPA Filter

•Removes smaller contaminated particles up

to 0.3 microns from the air flowing through

the unit and has an efficiency rating of

99.97%. The HEPA filter is recommended to

be changed as it becomes loaded, the

airflow capacity of the unit decreases, and

the pressure gauge at the control panel

exceeds 2.6 inches on high speed (1.9 inches

on low speed) of W.C.

UNIT SET UP & START UP

•The unit is to be operated away from doorways or other

make-up air sources. Properly set up the exhaust and seal off

any opening. Do not exhaust into uncontaminated or

occupied areas.

•Before powering the unit on:

‣lock the two rolling casters to keep the machine in place

‣confirm the rocker switch is in the off position

‣plug in the power supply cord

•To start the machine, select the speed by

pressing the top for high and the bottom for low.

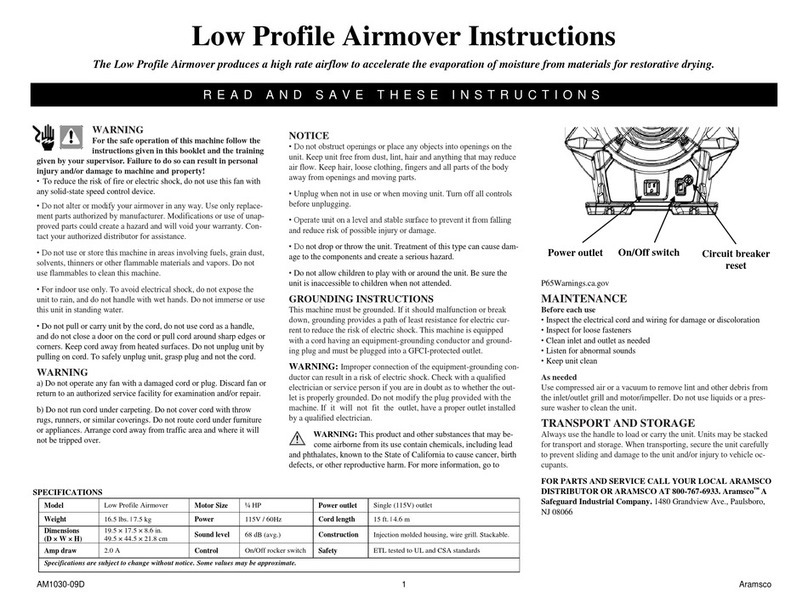

ELECTRICAL REQUIREMENTS

The SYCLONE requires a minimum of 115 V, 60 Hz, 9.5

amp, power supply for normal operation. The unit requires

an industrial grade 12/3 cord, in good condition. Do not

use a damaged cord. The cord should be properly

grounded (ground pin on the plug) and the continuous

length should not exceed 50 feet in for proper operation.

Do not expose the unit or power cord to water.

⚠CAUTION ⚠

DO NOT OPERATE THE SYCLONE WITHOUT THE HEPA FILTER INSTALLED!

OPERATING WITHOUTTHE HEPA FILTER INSTALLED OR USING

NON-APPROVED POWER CORDS MAY CAUSE DAMAGE TO THE

ELECTRICAL SYSTEM AND/OR MECHANICAL COMPONENTS.

FAILURE TO COMPLY WILL VOID THE WARRANTY.