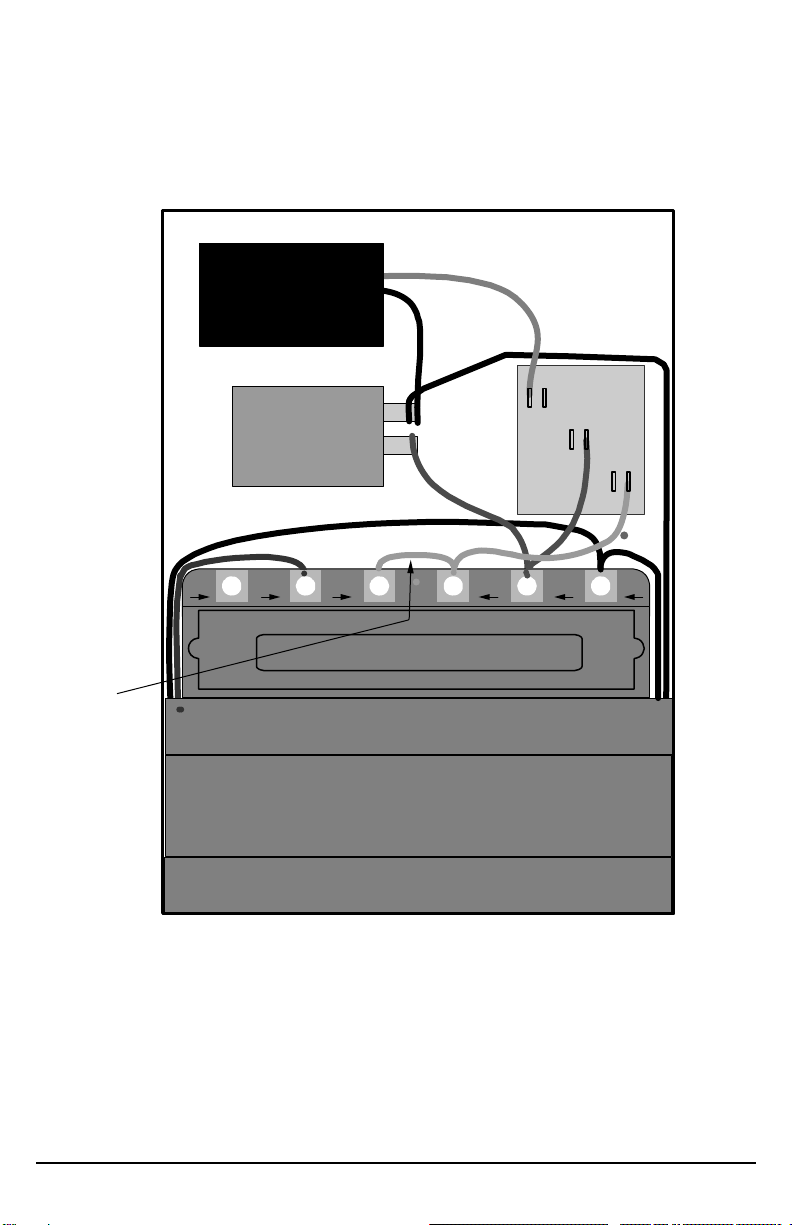

© 2009 SymCom, Inc. All Rights Reserved 8

TROUBLESHOOTING

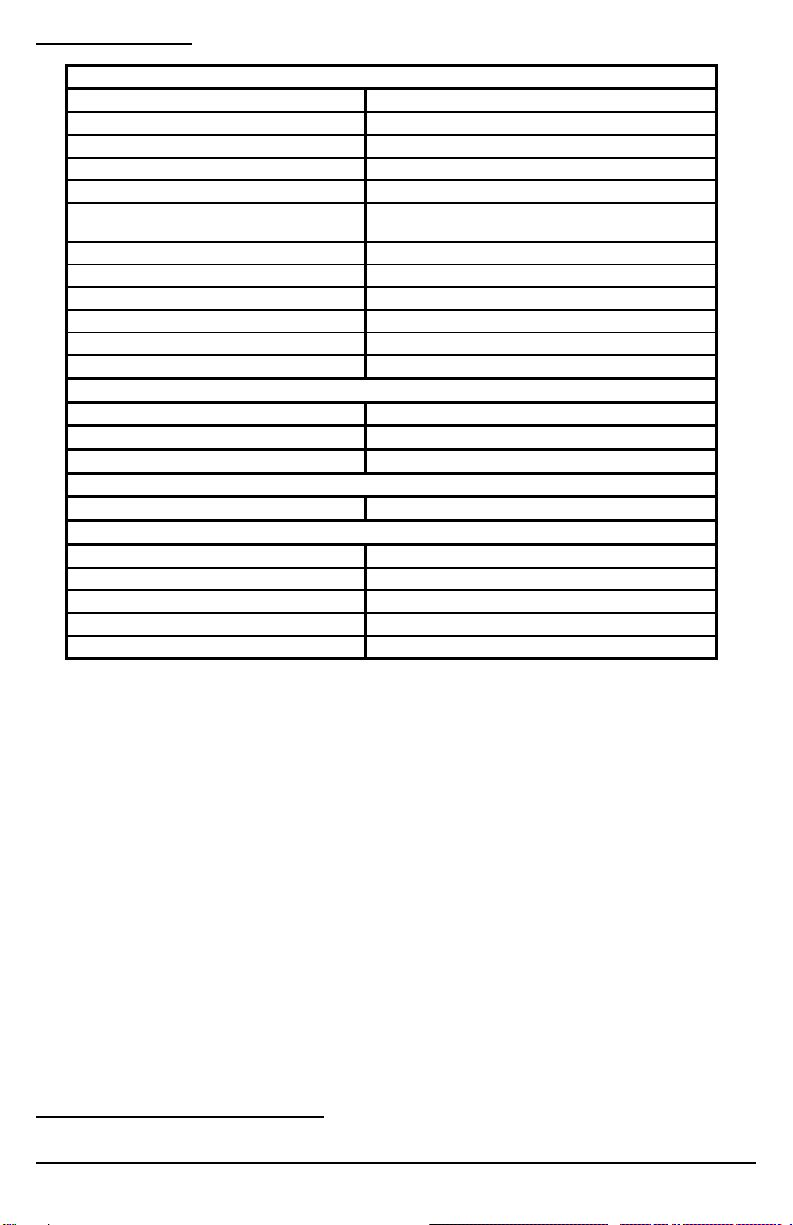

RUN

LIGHT CAL

LIGHT PROBLEM or FUNCTION CORRECTIVE ACTION

On Steady Off RUN:

Pump is running—or ready to

run—no problems in operation

If pump is not running, check for

loose wiring and ensure proper

function of pressure or float

switches.

On Steady On Steady CAL: The PumpSaver®Plus is in

the calibration process. None

Off On Steady

CAL COMPLETE:

The PumpSaver®Plus has

calibrated, the RESTART

DELAY/ CALIBRATION knob was

left in the CAL position. Pump is

off.

Pump will restart as soon as the

RESTART DELAY/

CALIBRATION knob is rotated out

of the CAL position.

Off Off

OFF / MANUAL RESTART: The

pump is not running. Either the

PumpSaver®Plus has tripped on

dry-run, dead-head, or

overcurrent while the RESTART

DELAY/ CALIBRATION knob was

in the RESET position or source

power is not present.

If knob is in the RESET position,

rotate out of RESET—If the CAL

light blinks, check for an

overcurrent condition. If the RUN

light blinks, look for a dry-run or

dead-head condition. If no lights

come on, check incoming power

for adequate voltage.

Blinking Off

DRY RUN / DEAD HEAD:

The PumpSaver®Plus has shut

the pump off due to a dry run or

dead head condition. The unit is

timing through the restart delay

and will try to restart.

Check for restricted flow or

inadequate supply of liquid.

Off Blinking

OVERCURRENT:

The PumpSaver®Plus has shut

the pump off due to an

overcurrent condition. The unit is

timing through the restart delay

and will try to restart if line

voltage is at an acceptable level.

Check for low or high voltage or

jammed pump impellers. If these

conditions do not exist, recalibrate

the unit while it is drawing higher

current (amps should not exceed

SFA).

Blinking

alternately

with the

CAL Light

Blinking

alternately

with the

RUN Light

VOLTAGE FAULT:

The PumpSaver®Plus is

preventing the pump from starting

due to voltage problems. The

voltage is being interrogated and

the unit will remain in this mode

until the voltage is at an

acceptable level.

If the unit remains in this state for

more than 5 seconds, check for

high or low voltage.

Blinking in

unison

with the

CAL.

LIGHT

Blinking in

unison with

the RUN

LIGHT

RAPID CYCLE:

The PumpSaver®Plus has shut

down on rapid cycling. Power

must be removed and reapplied

to reset the unit.

Check for a broken bladder in the

pressure tank (if used), or check

for a defective pressure or float

switch.