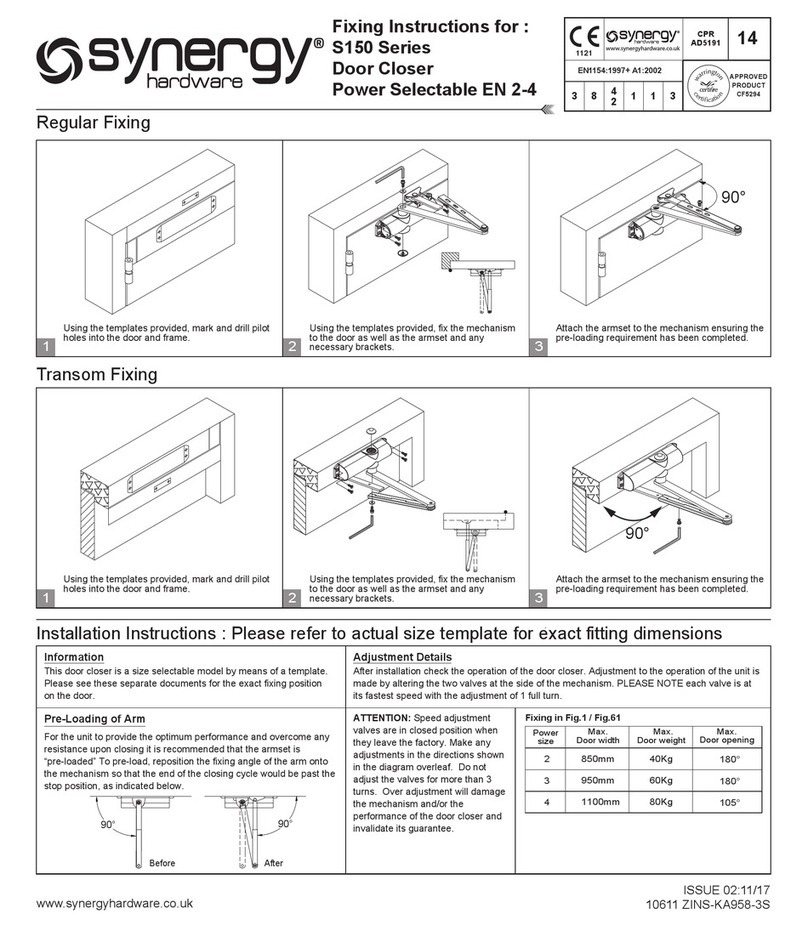

Parallel Fixing

Installation and Maintenance Instructions:

Using the templates provided, mark and

drill pilot holes into the door and frame.

Using the templates provided, fix the mechanism to the door as well

as the armset and the parallel arm bracket.

1 2 3

Rotate the bottom pinion at approximately

90° with a wrench as illustrated and

then assemble the main arm.

4

Make sure the main arm is parallel to the door.

Then attach the connecting arm.

Maintenance

1.Once the unit has been correctly

fitted it is recommended that

periodic checks (every six

months) are carried out to ensure

all fixings are tight and the door

closes freely and positively into

the frame, without slamming.

2.A light oil lubricant (non-graphite)

should be applied to the moving

joints and exposed pivot points.

After Installation

1.When the closer operates to close

the door from its maximum opening

position, it should ensure the lock

latchbolt and any seals are overcome

and the leaf returned into its frame.

2.When the door is slightly open and

the latch bolt resting against the

strike, release the door to ensure the

leaf fully closes into its frame.

Warning

1.Please note the minimum power size requirement for fire / smoke

door assemblies is 3 as required by Approved Document B.

2.Do not install mechanical hold open devices on fire / smoke door

assemblies.

3.Take care not to exceed the maximum opening angle as detailed

above.

4.Care and attention must be taken when adjusting any of the units

control valves to avoid damage through over adjustment.

5.All Synergy Door Closer units are sealed for life and the internal

components assembled under high load, therefore, tampering

with the mechanism is to be strictly avoided.

No.4 Backcheck

No.1 Closing

No.2 Latching

Adjusting the force

No.3 Delayed Action (OPTIONAL)

Closer Adjustments

After ensuring all fixings are tightened, operate the door

closer to check its performance, making adjustments as

necessary.

Fast Slow

Factory preset

CW:Clockwise CCW:Counterclockwise

Fixing in Fig.66

3

Max.

Door width Max.

Door weight

950mm 60Kg

Power

size

180°

Door opening

Max.

0

Number of turns

No.1 180°

750mm 20Kg 7CCW

2180°

850mm 40Kg 4CCW

The following adjustment valves have a maximum

adjustment of 1 full turn per valve.

PLEASE NOTE over adjustment will damage the

mechanism and/or the performance of the door

closer and invalidate its guarantee. Adjust

Backcheck (valve #4) and the optional Delayed

Action (valve #3) before adjusting the Closing

Speed (valve #1) and Latching Action (valve #2).

www.synergyhardware.co.uk

Fixing Instructions for :

S500 Series

Door Closer

Power Adjustable EN 2-4

APPROVED

PRODUCT

CF5294

CPR

AD5194

1121

15

BS EN1154:1997+ A1:2002

384

2114

www.synergyhardware.co.uk