5

Limited One-Year Non Wearing Parts Warranty

Synesso, Inc and/or your Distributor warrants to the original purchaser that Synesso espresso machines are

free from defects in materials and workmanship under normal use and service for the period commencing

upon the date of shipping and connuing for 12 months from the original date of shipment. Synesso will

make a good faith eort for prompt correcon or other adjustment with respect to any non wearing part

that proves to be defecve within the limited warranty period. This Limited Warranty is condional upon

proper use of the machine by the purchaser.

This Limited Warranty does not cover defects or damage resulng from: accident, misuse, abuse, shipping

damage, neglect, unusual physical, electrical or electromechanical stress, unauthorized customer modica-

ons or improper water ltraon.

Proper water ltraon and regular lter changes are a requirement to keep your factory warranty valid

and your machine funconing properly. It is highly recommended that you contact a professional water

ltraon specialist in your area and have your water tested to determine the proper ltraon system. It is

important to note that many municipalies change their water sources throughout the year, so addional

water tests may become necessary.

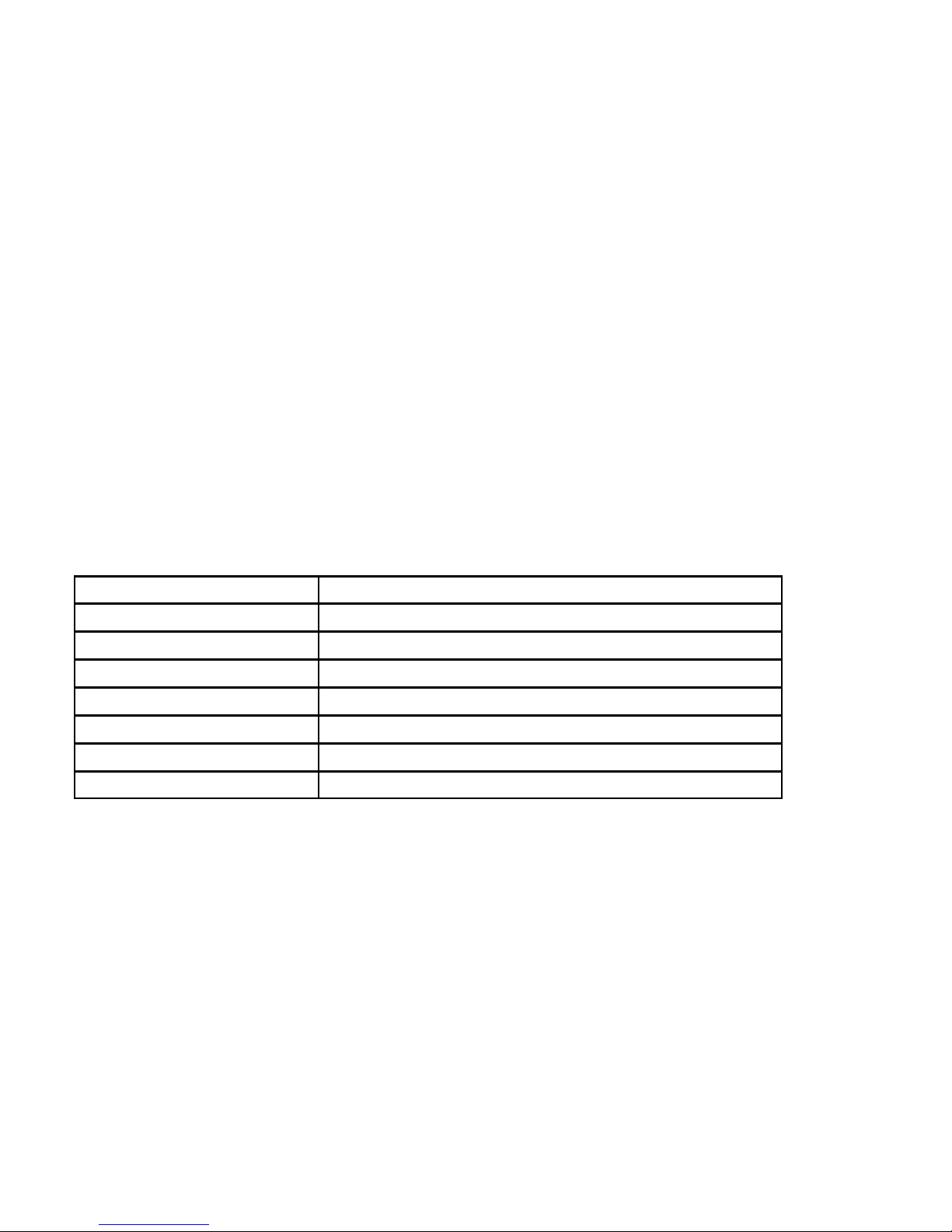

Water Standards to keep your warranty valid:

In Synesso’s experience, Everpure Claris and Cirqua formulator systems can produce a re-

sult that can damage the Synesso stainless steel tanks. Use of either system is highly dis-

couraged and will void the water related parts of the machine warranty.

Any part which is determined to be defecve in materials or workmanship should be returned to Synesso or

to an authorized service locaon, shipping costs to be determined depending upon the circumstances.

Synesso may repair or replace the product or part with new or factory refurbished equipment at Synesso’s

sole discreon. If the product or part is determined to be defecve and in compliance with the Limited War-

ranty condions, the replacement part or product will be returned to the purchaser with shipping prepaid.

.

Many jurisdicons have codes and regulaons governing sales, construcon, installaon, and/or use of

products for certain purposes, which may vary from area to area. While Synesso aempts to assure that its

products comply with such codes, it cannot guarantee compliance and cannot be responsible for how the

product is used or installed.

Total Dissolved Solids (TDS) 30 to 200 ppm (parts per million)

Total Hardness - in ppm Less than 85 ppm

Total Hardness – in grains 3 to 5 grains (divide ppm by 17.1 to get grains)

pH 6.5 pH to 7.5 pH

Chloride 0 ppm – any Chlorides can be corrosive and harmful

Total Alkalinity Less than 100 ppm

Chlorine 0 ppm

Iron 0 ppm

WARRANTY & WATER STANDARDS