5

Mounting Electromagnetic Bin Vibrators

The correct location of electromagnetic vibrators is of prime importance in obtaining maximum efficiency from the

selected model.

CURVED SURFACES Figure 1

Select a bracket made from a channel section or a bent plate when

mounting a vibrator to a curved surface. A center gusset is required for all

totally enclosed vibrators, and two blocks of sufficent height to contact the

curved surface are required for models V-75 and V-500. The selected gusset

or block must be securely welded to the bracket and curved surface. This

arrangement is required to stiffen the mounting and transmit vibrations

directly to the hopper contents. Mounting bolt heads can be welded to the

brackets underside.

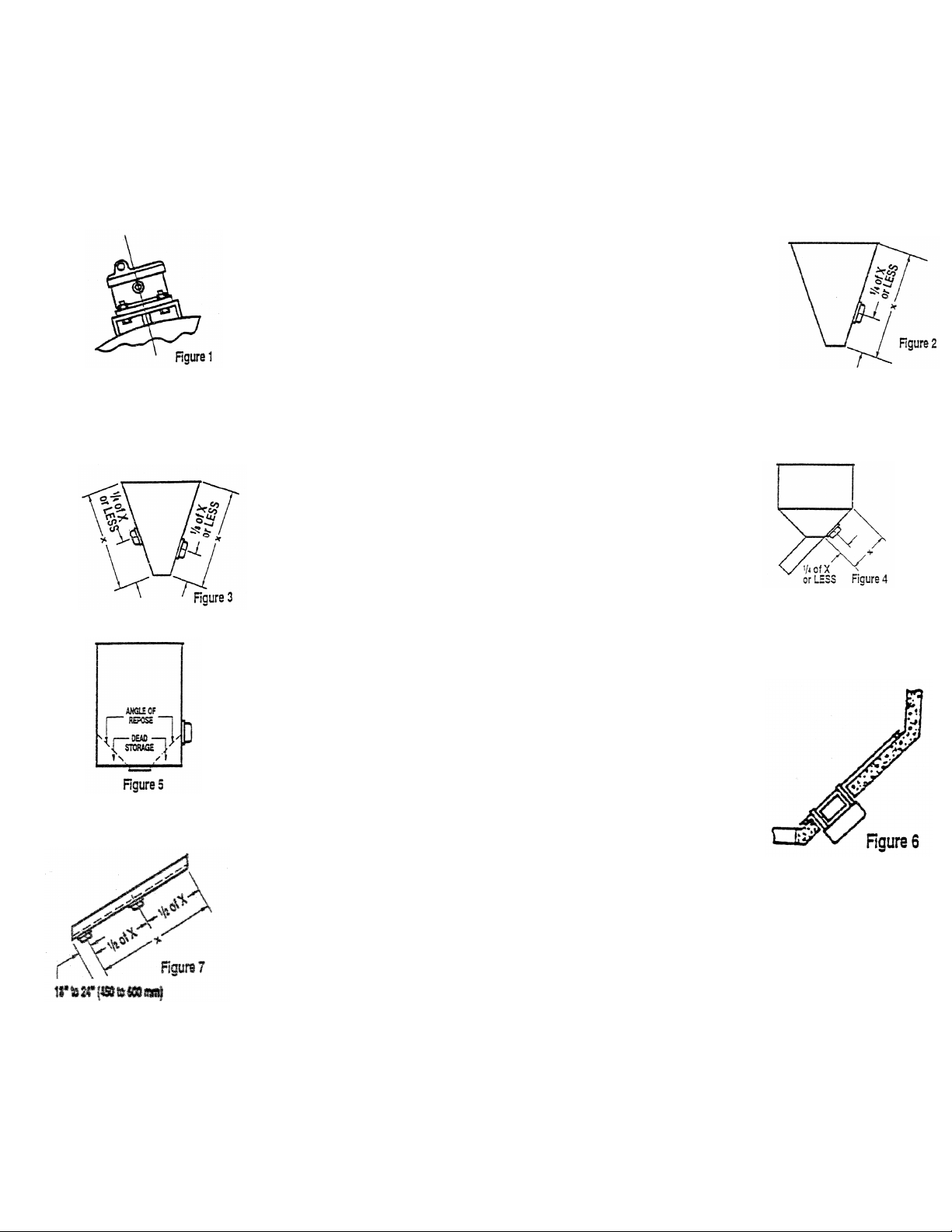

CONICAL HOPPERS Figure 2 The vibrator should be bolted, as above, directly to the hopper face, 12 to 18 inches

(300 to 450mm0 or less from the discharge.

RECTANGULAR HOPPERS Figure 3

Mount each vibrator to the hopper wall the same as on a conical

hopper. If a stiffener obstructs mounting, mount the vibrator in the

middle of the panel next to the stiffener. A second vibrator, if required,

should be bolted on the opposite face at a slightly higher elevation.

HOPPER WITH SLOPING DISCHARGE Figure 4 Mount the vibrator

on the centerline of the hopper, as close to the discharge as possible. An additonal vibrator

may be required on the discharge chute.

RECTANGULAR OR CYLINDRICAL BINS WITH FLAT BOTTOM DISCHARGE Figure 5

Mount directly to the side of the bin, just below the point where the materials’ natural angle of

repose intersects the side, as shown in the sketch.

CONCRETE OR WOODEN HOPPER Figure 6 If a wooden hopper is lined

with thin sheet, the vibrator mounting bolts must attach to the lining.

Ina concrete hopper, a steel plate, secured across the top, should be placed

vertically from the discharge opening inside the hopper, along the side to

which the vibrator will be mounted. At about one-quarter or less of the

distance from the discharge to the vertical side, an opening should be cut (or allowed for in the

hopper construction plans) to permit bolting the vibrator to the steel plate.

INCLINED CHUTES Figure 7 Chutes less than 10 to 12 feet (3 to 3.6 m) long are usually

equipped with just one vibrator located considerably below center. Allow for the vibrator to be

moved about one foot in either direction.

On chutes requiring more than one vibrator, the first one should be located 18 to 24 inches

(450 to 600 mm) from the outlet. The second unit should be mounted about half way between

this vibrator and the upper end.

NOTE: Vibrators on hoppers should operate only when the hopper is open to to flow.

Otherwise, vibrations may pack the hopper contents.