Master Language is English Hot Runner System Installation Guide SVC-17-0001_EN-Rev11

RESTRICTED: Property of Synventive. - 275 - All rights reserved. Errors and omissions excepted

For limited third party distribution based on need and intended use. © 2019 Synventive Molding Solutions

H O T R U N N E R T E C H N O L O G Y

Hot Runner System Installation Guide

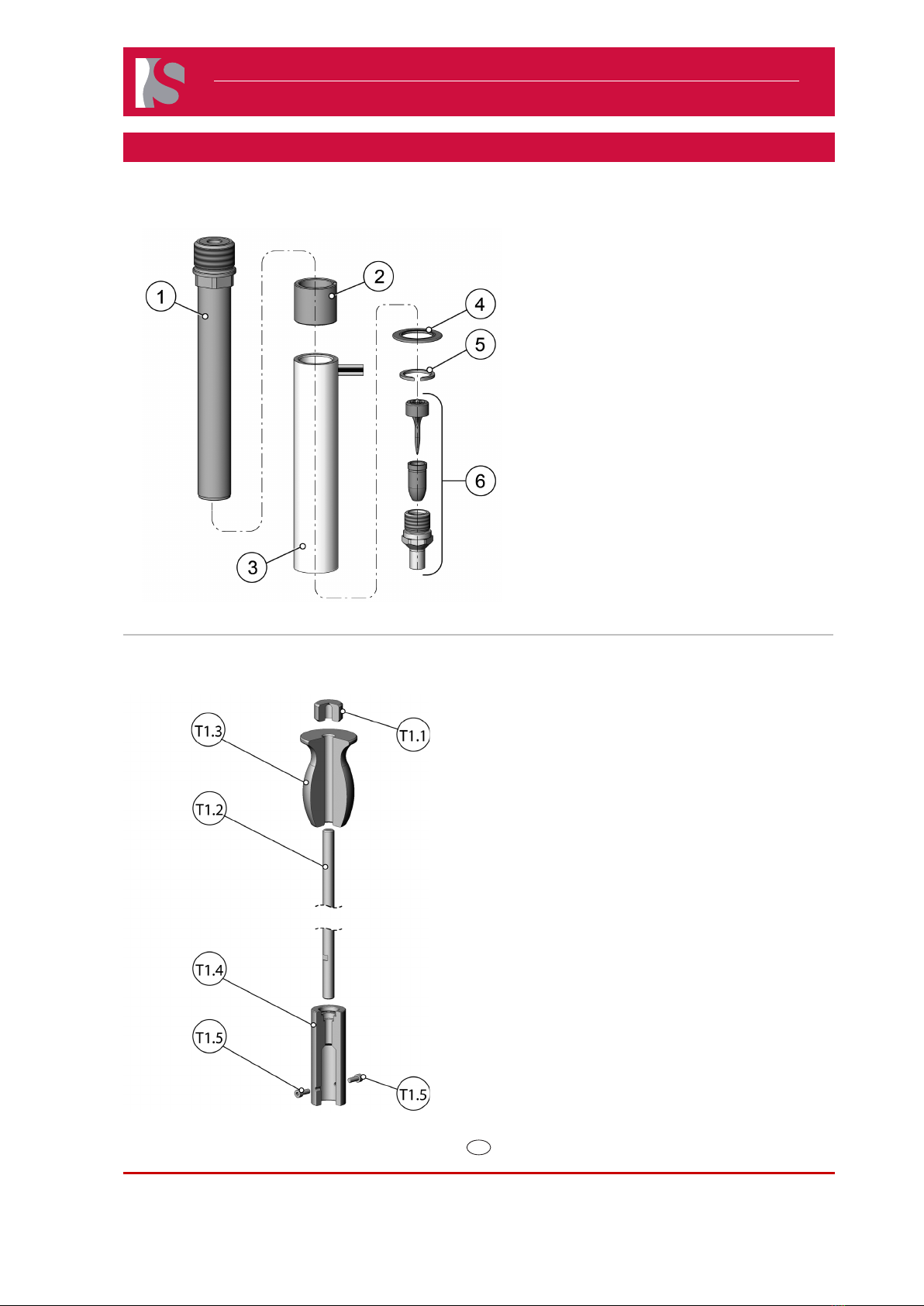

Service and Maintenance / Nozzle 06E Series

10.1.1.2 Disassembly the Nozzle 06E

Disassembling the Nozzle Tip

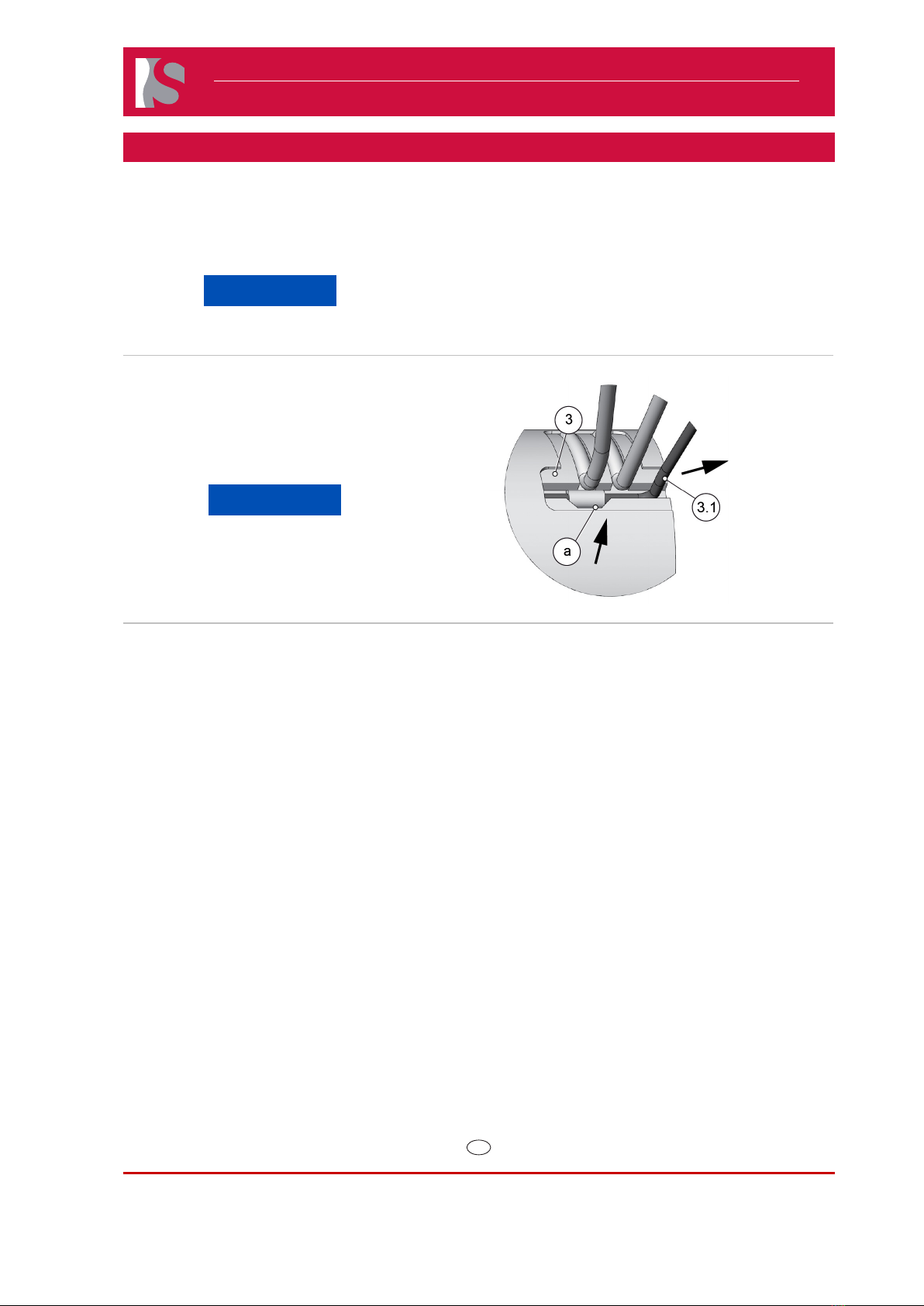

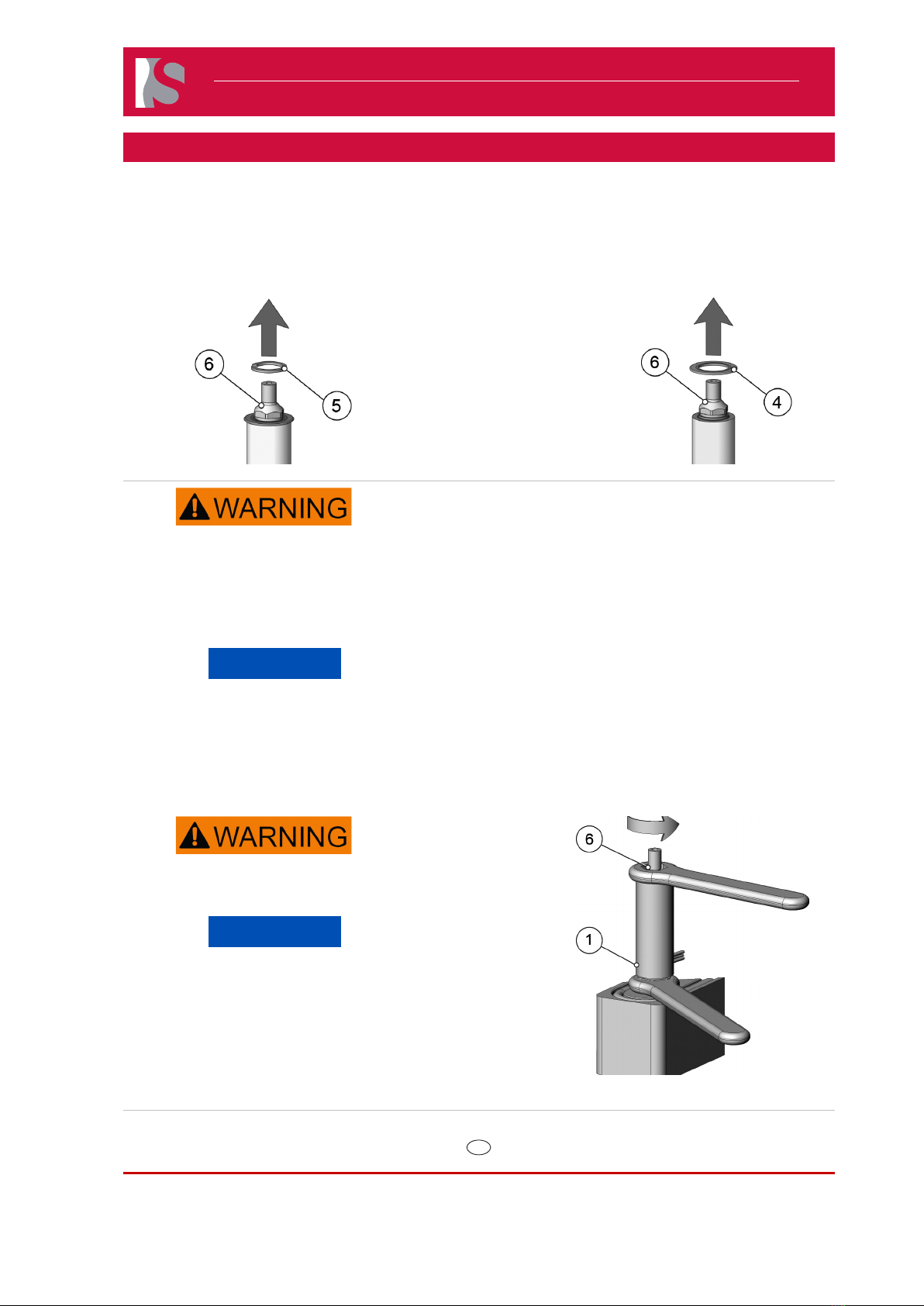

1) Remove the circlip (5) from the nozzle tip (6).

Doc006490.png

2) Remove the component ring version 02(4)

Doc006489.png

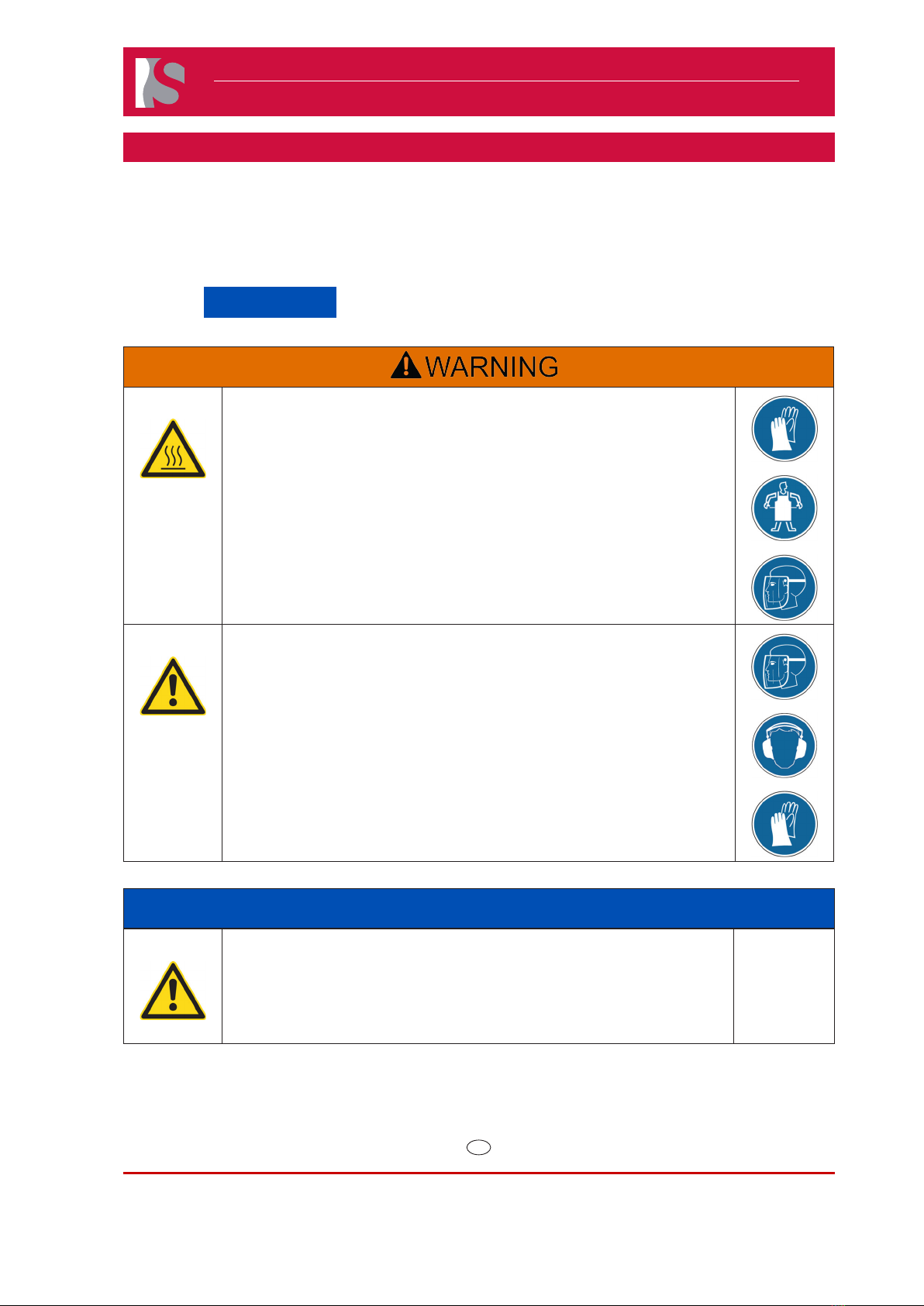

Hot Surfaces Hazard

Following works must be carried out by qualied persons.

Use personal protective equipment, such as gloves, apron, sleeves

and face protection, to guard against burns

Contact between the skin and the hot nozzle could result in burns.

NOTICE

To dismount the nozzle tip from the nozzle, if there is plastic

material in the nozzle, the tip must be heated-up.

Never use an acetylene or welding torch, as severe nozzle

damage can occur from over-heating.

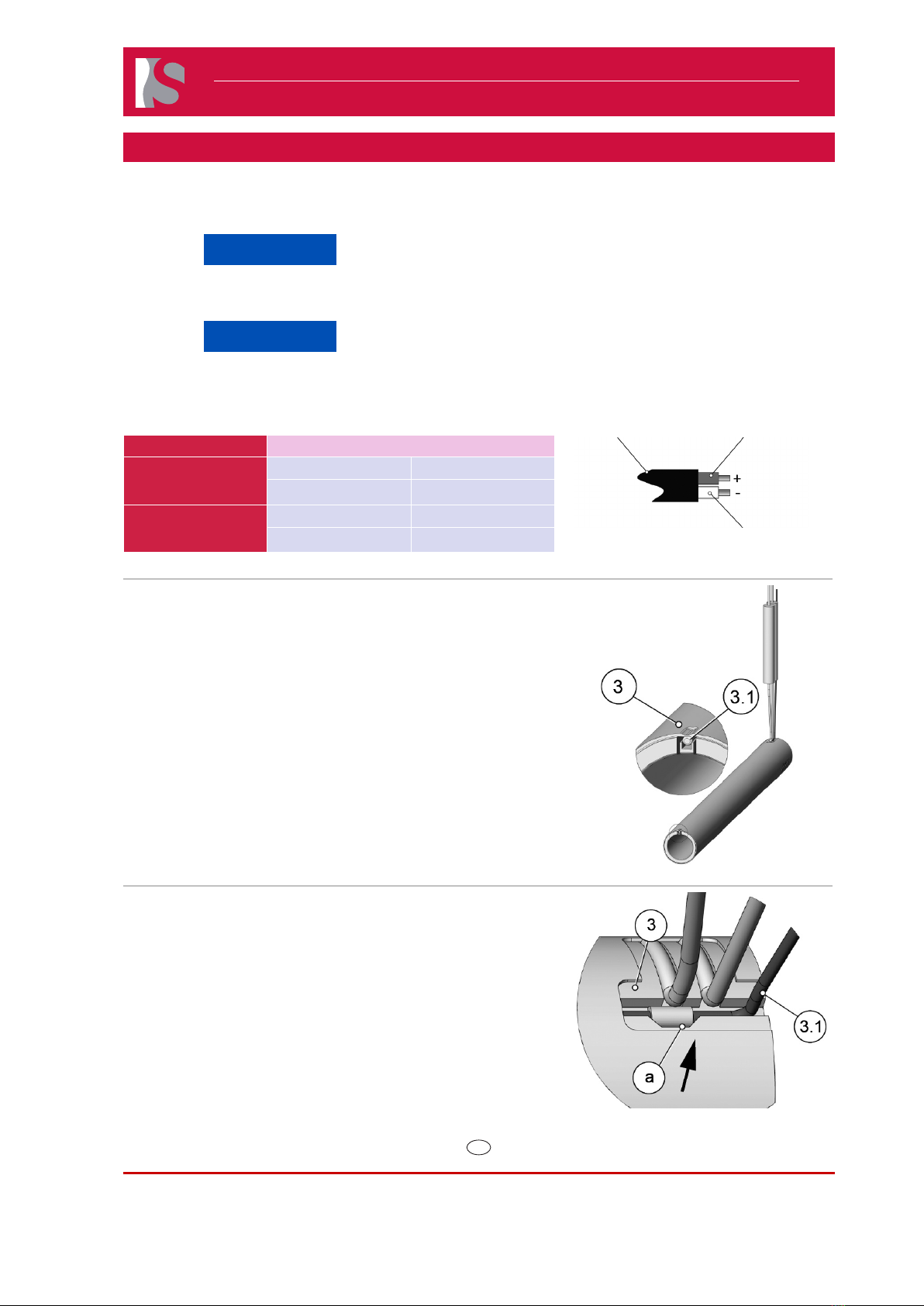

3) Heat the nozzle tip (2) using a heat gun to the maximum temperature of

200 °C (392 °F).

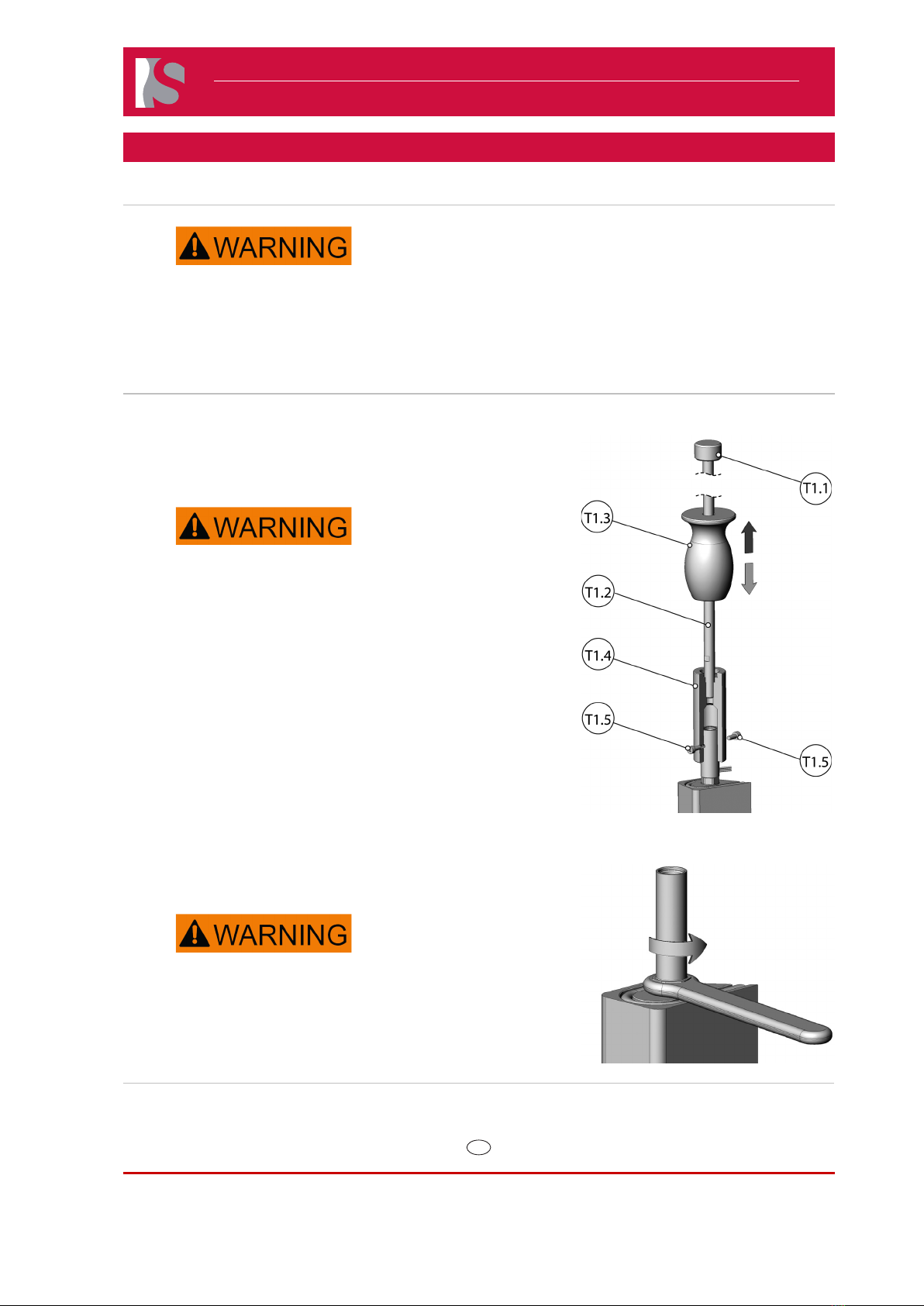

Hot Surfaces Hazard

The nozzle is still hot.

NOTICE

Unscrewing the nozzle tip may cause the nozzle to start

rotating together with the nozzle tip, which could result in

leakage at the base of the nozzle.

4) Hold the nozzle body (1) rmly using an engineer’s wrench at the

hexagonal shape.

5) Unscrew the nozzle tip (6) from the nozzle body (1) using an

engineer’s wrench. Doc006494.png