Master Language is English Hot Runner System Installation Guide SVC-17-0001_EN-Rev13

RESTRICTED: Property of Synventive. - 85 - All rights reserved. Errors and omissions excepted

For limited third party distribution based on need and intended use. © 2021 Synventive Molding Solutions

H O T R U N N E R T E C H N O L O G Y

Hot Runner System Installation Guide

Service and Maintenance / Actuator HB Series

8.1.1 Actuator HB Series

8.1.1.1Technical Data

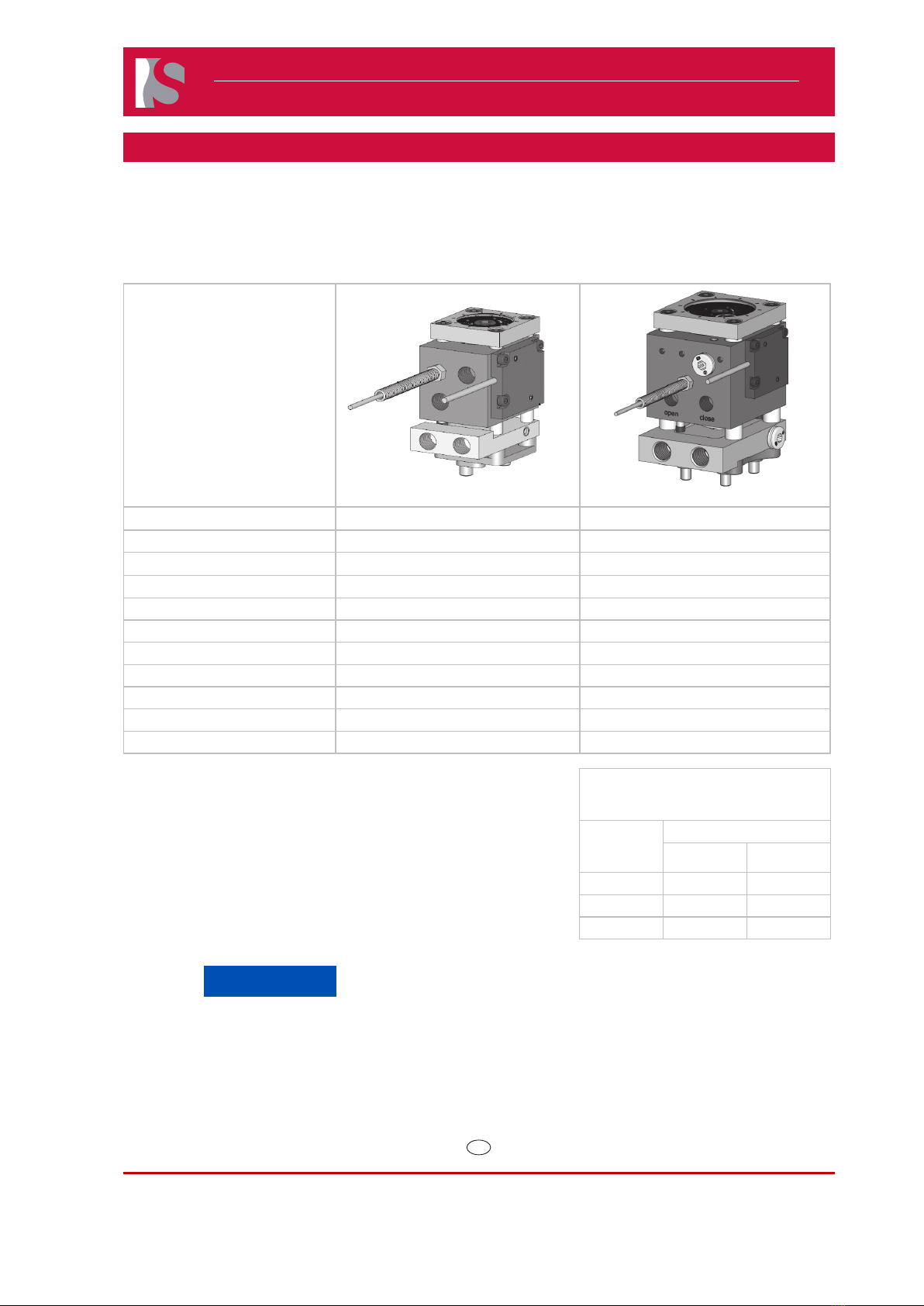

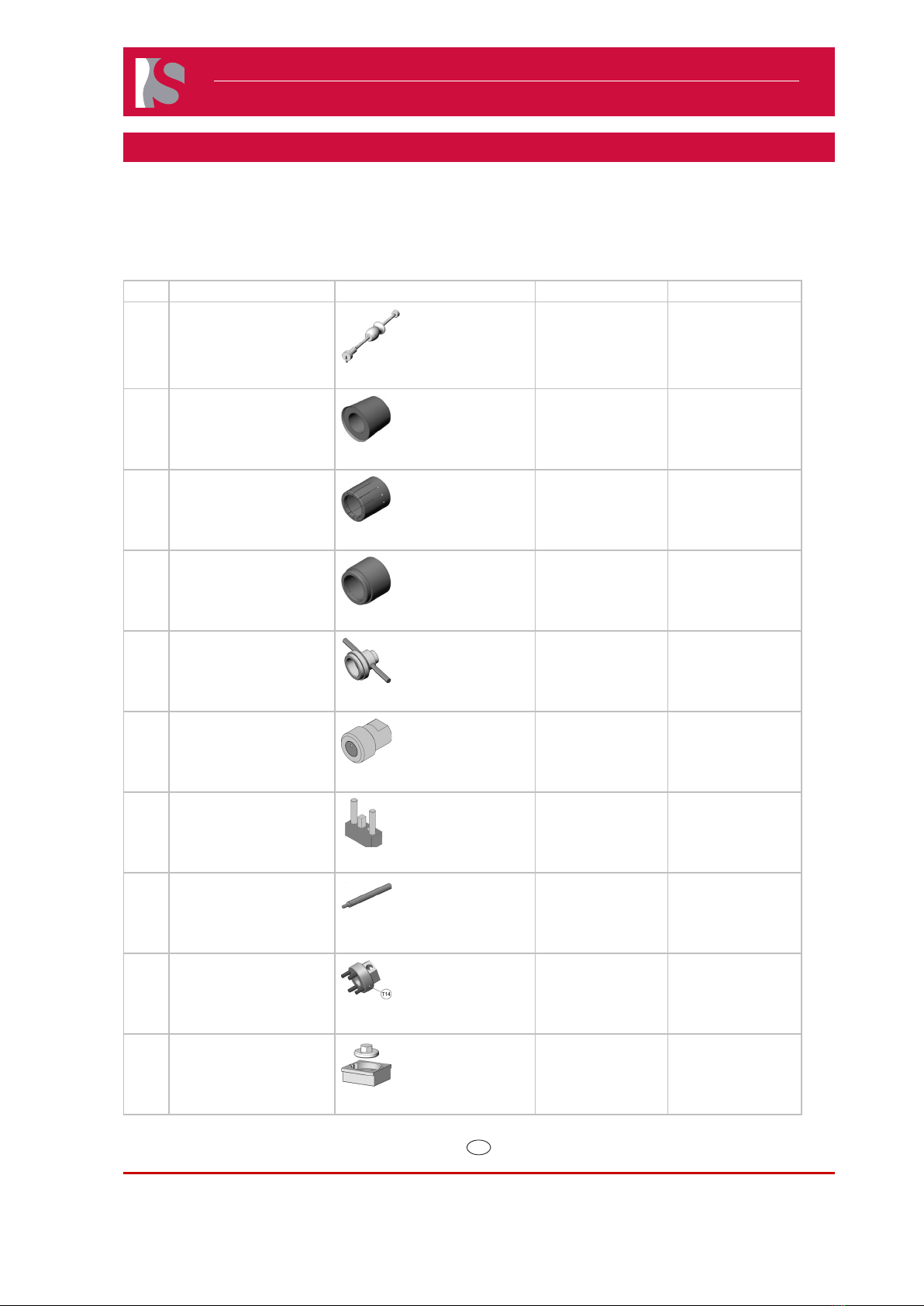

Doc006521.png Doc006419.png

Parameters HB2508# HB4016#

Valve Pin Diameter 3 mm, 3.8 mm 5 mm, 6 mm, 8 mm, 12 mm

Nozzle Series 06E, 09E 12E, 16E, 22E

Pin Adjustment +/- 1 mm +/- 1.5 mm

MIn/Max Close Forces 1963/2945N 5027/7540N

Min/Max Open Forces 443/2267N 3506/5259N

Min/Max. Hydraulic Pressure 40/60 bar (600/870 psi) 40/60 bar (600/870 psi)

Valve Pin Stroke 8 mm 16 mm

Hydraulic Connections M10x1.0 M10x1.0

Cooling Temperature 30-60°C 30-60°C

Cooling Connections M10x1.0 M12x1.5

Recommended HB4016 Actuator Pressure

Settings when Hydraulic Manifold Block

is not Supplied on Hot Runner

Pin

Diameter

(mm)

Actuator Pressure

PSI Bar

5 300 20

Thermocouple and Position Sensor optional on all models.

Maximum 3 Actuators per cooling zone on all models.

6 450 30

8 & 12 600 40

NOTICE

To ensure long life and continued flawless operation of the actuator, we recommend using a service

medium that complies with the requirements of classification 21/18/13 pursuant to ISO 4406.

The coolant should be properly modified e.g. filtered water with an anti-corrosion and frost proof agent.

After switching off the Hot Runner heater, the cooling for the actuator should remain on for at least

15 minutes, to avoid damage to the Actuator seals and the position sensor.