Table of contents

1 General ...............................................5

1.1 Indications regarding the instructions for use and installation .........5

1.2 Symbols ..................................................5

1.3 Copyright .................................................6

1.4 Warranty..................................................6

1.5 Standards applied ..........................................6

2 Safety.................................................7

2.1 Intended use ..............................................7

2.2 Fundamental hazards .......................................7

2.3 Hazards due to electric energy ................................7

2.4 Maintenance and repair work..................................8

3 Design and function .....................................9

3.1 Scope of delivery of the fully automatic lling system 3200 ...........9

3.2 Optional accessories ........................................9

3.3 Design of the fully automatic lling system 3200 .................10

3.3.1 Design of the control unit ....................................11

3.3.2 Design of the connection ange...............................11

3.3.3 Design of the pre-lter ......................................12

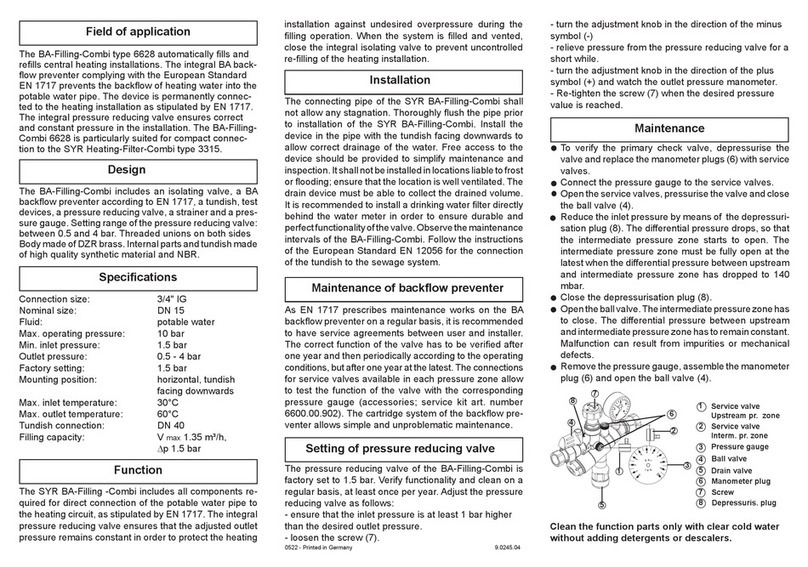

3.3.4 Design of the BA backow preventer ...........................12

3.3.5 Design connection set for heating water conditioning (accessories) ...13

3.4 Function .................................................14

4 Transport and storage ..................................15

4.1 Transport ................................................15

4.2 Storage..................................................15

5 Installation and commissioning ..........................16

5.1 Safety instructions for installation and commissioning..............16

5.2 Installation ...............................................17

5.2.1 Mounting of the connection ange ............................17

5.2.2 Mounting of the fully automatic lling system.....................17

5.3 Mounting of the connection set for heating water conditioning .......18

5.4 Commissioning of the fully automatic heating system ..............19

6 Operation.............................................22

6.1 Control panel .............................................22

6.1.1 Description of the menu items ................................25

6.1.2 Adjustable parameters ......................................26

6.1.3 Adjustment of the limit value for volume-based leakage ............28

6.1.4 Range of cartridges and cartridge replacement ...................28

6.2 SYR-App ................................................30

6.3 Emergency shut-off function .................................30

3