D900-14-00 4 I56-0983-008

©System Sensor 2000

Three-Year Limited Warranty

System Sensor warrants its enclosed sounder/strobe to be free from de-

fects in materials and workmanship under normal use and service for a

period of three years from date of manufacture. System Sensor makes no

other express warranty for this sounder/strobe. No agent, representative,

dealer, or employee of the Company has the authority to increase or alter

the obligations or limitations of this Warranty. The Company’s obligation

of this Warranty shall be limited to the repair or replacement of any part of

the sounder/strobe which is found to be defective in materials or work-

manship under normal use and service during the three year period com-

mencing with the date of manufacture. After phoning System Sensor’s toll

free number 800-SENSOR2 (736-7672) for a Return Authorization number,

send defective units postage prepaid to: System Sensor, Repair Depart-

ment, RA #__________, 3825 Ohio Avenue, St. Charles, IL 60174. Please

include a note describing the malfunction and suspected cause of failure.

The Company shall not be obligated to repair or replace units which are

found to be defective because of damage, unreasonable use, modifica-

tions, or alterations occurring after the date of manufacture. In no case

shall the Company be liable for any consequential or incidental damages

for breach of this or any other Warranty, expressed or implied whatsoever,

even if the loss or damage is caused by the Company’s negligence or fault.

Some states do not allow the exclusion or limitation of incidental or conse-

quential damages, so the above limitation or exclusion may not apply to

you. This Warranty gives you specific legal rights, and you may also have

other rights which vary from state to state.

The sounder and/or strobe will not work without power. The sounder/

strobe gets its power from the fire/security panel monitoring the alarm

system. If power is cut off for any reason, the sounder/strobe will not pro-

vide the desired audio or visual warning.

The sounder may not be heard. The loudness of the sounder meets (or

exceeds) current Underwriters Laboratories’standards. However, the

sounder may not alert a sound sleeper or one who has recently used drugs

or has been drinking alcoholic beverages. The sounder may not be heard if

it is placed on a different floor from the person in hazard or if placed too

far away to be heard over the ambient noise such as traffic, air condition-

ers, machinery or music appliances that may prevent alert persons from

hearing the alarm. The sounder may not be heard by persons who are

hearing impaired.

The signal strobe may not be seen. The electronic visual warning signal

uses an extremely reliable xenon flash tube. It flashes at least once every

three seconds and exceeds current Underwriters Laboratories standards

for private mode viewing. The visual warning signal is suitable for direct

viewing and must be installed within an area where it can be seen by

building occupants. The strobe must not be installed in direct sunlight or

areas of high light intensity (over 60 foot candles) where the visual flash

might be disregarded or not seen. The strobe may not be seen by the visu-

ally impaired and is not intended to meet American Disabilities Act (ADA)

requirements.

The signal strobe may cause seizures. Individuals who have positive

photic response to visual stimuli with seizures, such as persons with epi-

lepsy, should avoid prolonged exposure to environments in which strobe

signals, including this strobe, are activated.

The signal strobe cannot operate from coded power supplies. Coded

power supplies produce interrupted power. The strobe must have an unin-

terrupted source of dc power in order to operate correctly. System Sensor

recommends that the sounder and signal strobe always be used in combi-

nation so that the risks from any of the above limitations are minimized.

WARNING

The Limitations of Sounder/Strobes

A

A

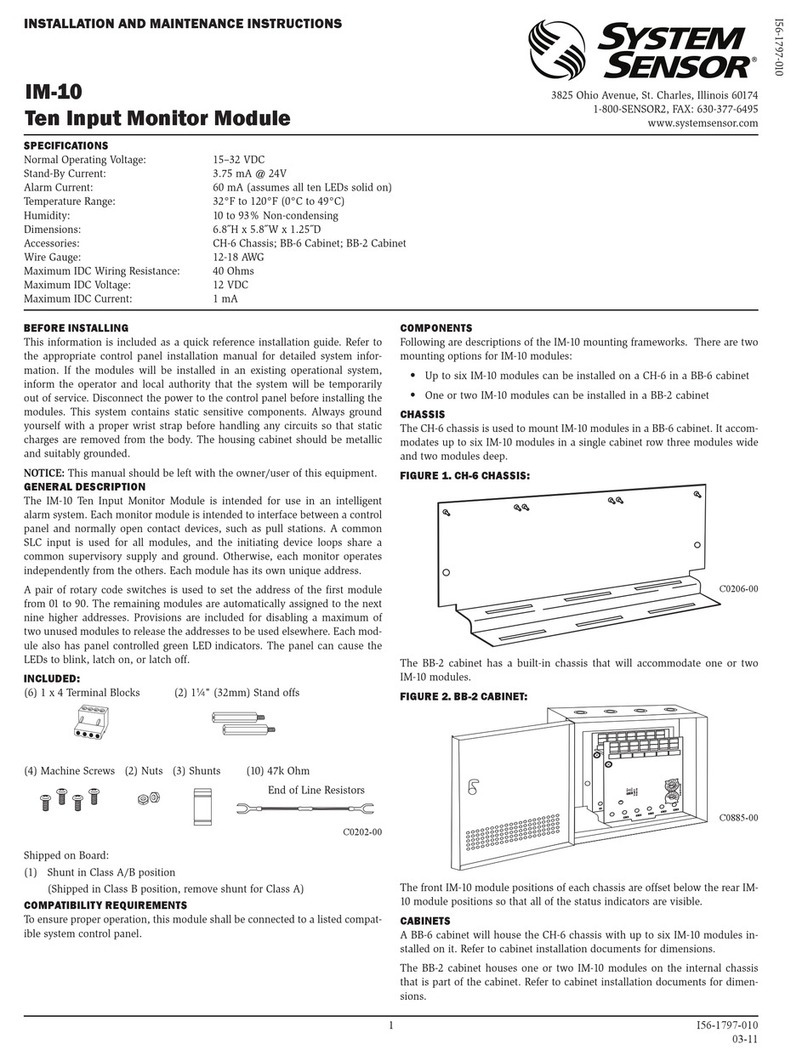

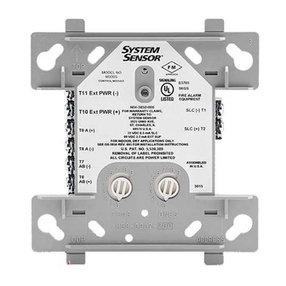

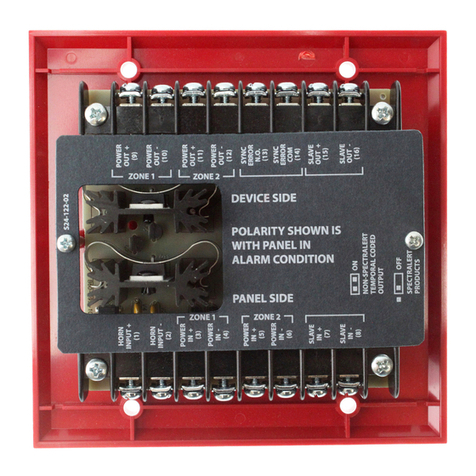

Figure 6: Mounting Diagram

1. Complete field wiring.

2. Mount unit to 411 /16″backbox with screws A.