D200-72-00 4 I56-1883-000

©2004 System Sensor

Three-Year Limited Warranty

System Sensor warrants its enclosed smoke detector to be free from defects in materials and workmanship under normal use and service for a

period of three years from date of manufacture. System Sensor makes

no other express warranty for this smoke detector. No agent, representa-

tive, dealer, or employee of the Company has the authority to increase

or alter the obligations or limitations of this Warranty. The Company’s

obligation of this Warranty shall be limited to the repair or replacement of

any part of the smoke detector which is found to be defective in materi-

als or workmanship under normal use and service during the three year

period commencing with the date of manufacture. After phoning System

Sensor’s toll free number 800-SENSOR2 (736-7672) for a Return

Authorization number, send defective units postage prepaid to: System

Sensor, Repair Department, RA #__________, 6581 Kitimat Rd, Unit# 6

Mississauga, Ontario L5N 3T5. Please include a note describing the mal-

function and suspected cause of failure. The Company shall not be obli-

gated to repair or replace units which are found to be defective because

of damage, unreasonable use, modifications, or alterations occurring

after the date of manufacture. In no case shall the Company be liable for

any consequential or incidental damages for breach of this or any other

Warranty, expressed or implied whatsoever, even if the loss or damage is

caused by the Company’s negligence or fault. Some states do not allow

the exclusion or limitation of incidental or consequential damages, so the

above limitation or exclusion may not apply to you. This Warranty gives

you specific legal rights, and you may also have other rights which vary

from state to state.

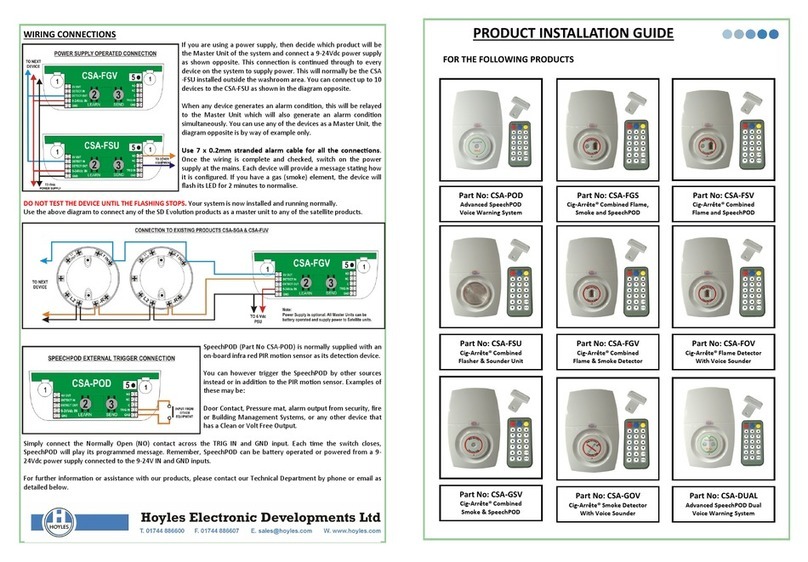

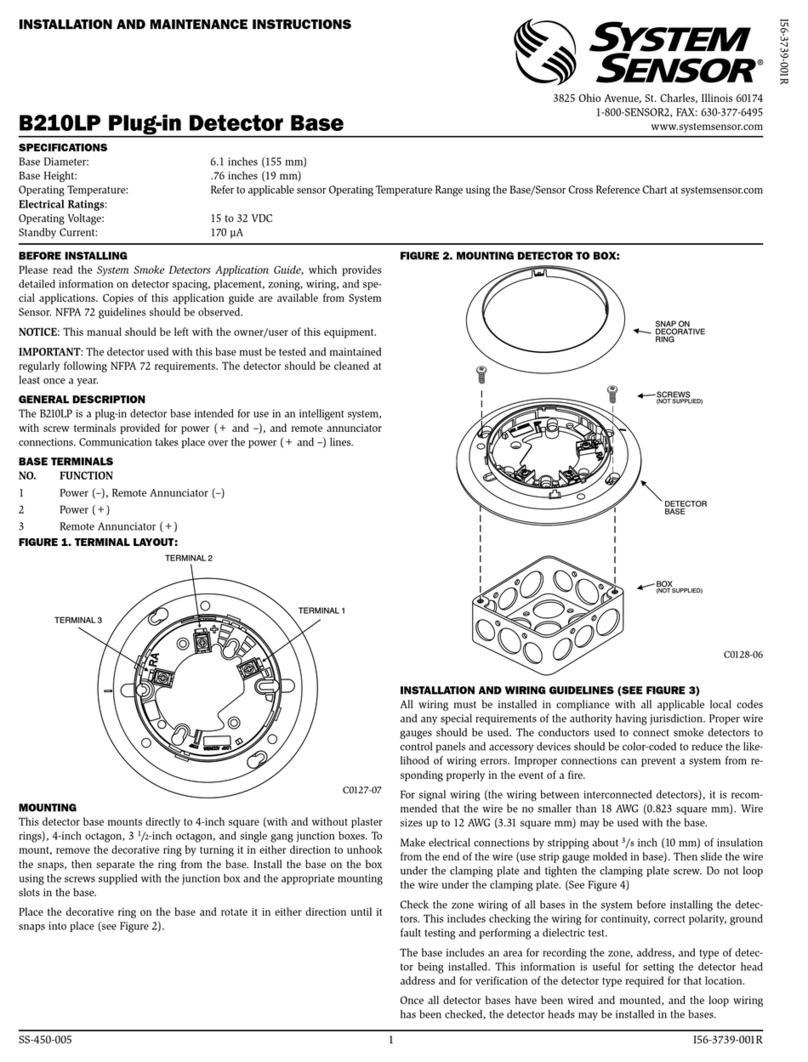

Figure 5: Installing Filtrex detector into base:

If a clogged filter was the cause of the trouble condition,

normal detector operation should resume automatically

within five minutes. If the trouble condition persists, the

detector must be returned for repair or replacement.

Installing Filtrex Into Base

1. Align the detector at a right angle to the base, with

the five wires and connector adjacent to the connector

receptacle as shown in Figure 5.

2. Plug the wired connector into the receptacle.

3. Rotate the detector into the base, making sure detec-

tor and base keyed fit is lined up. Turn the detector

clockwise until it snaps into place.

IMPORTANT: Filtrex will only operate with B501B-

FTXA.

FCC Statement

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This device may not cause harmful inter-

ference, and (2) this device must accept any interference received, including interference that may cause undesired operation.

Note: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful interference in a residential installation. This equipment generates,

uses and can radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interfer-

ence to radio communications. However, there is no guarantee that interference will not occur in a particular installation. If this equipment

does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following measures:

– Reorient or relocate the receiving antenna.

– Increase the separation between the equipment and receiver.

– Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

– Consult the dealer or an experienced radio/TV technician for help.

Please refer to insert for the Limitations of Fire Alarm Systems