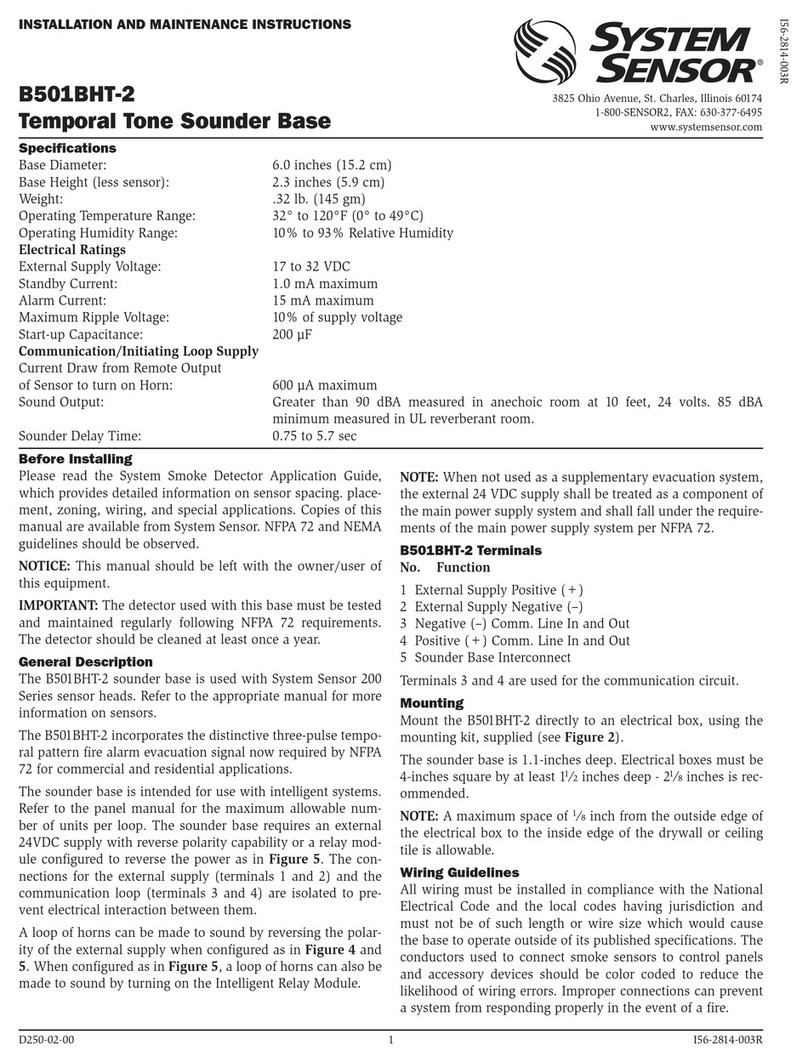

–

+

COMPATIBLE

CONTROL PANEL

(–) COM LINE

TO REST OF SYSTEM

(+) COM LINE

TO REST OF SYSTEM

LOOP

LOOP

UNIT 2

UNIT1 UNIT 3

COMM (+)

COMM (–)

(+) OUT

COMM (+)

COMM (–)

(+) OUT

COMM (+)

COMM (–)

(+) OUT

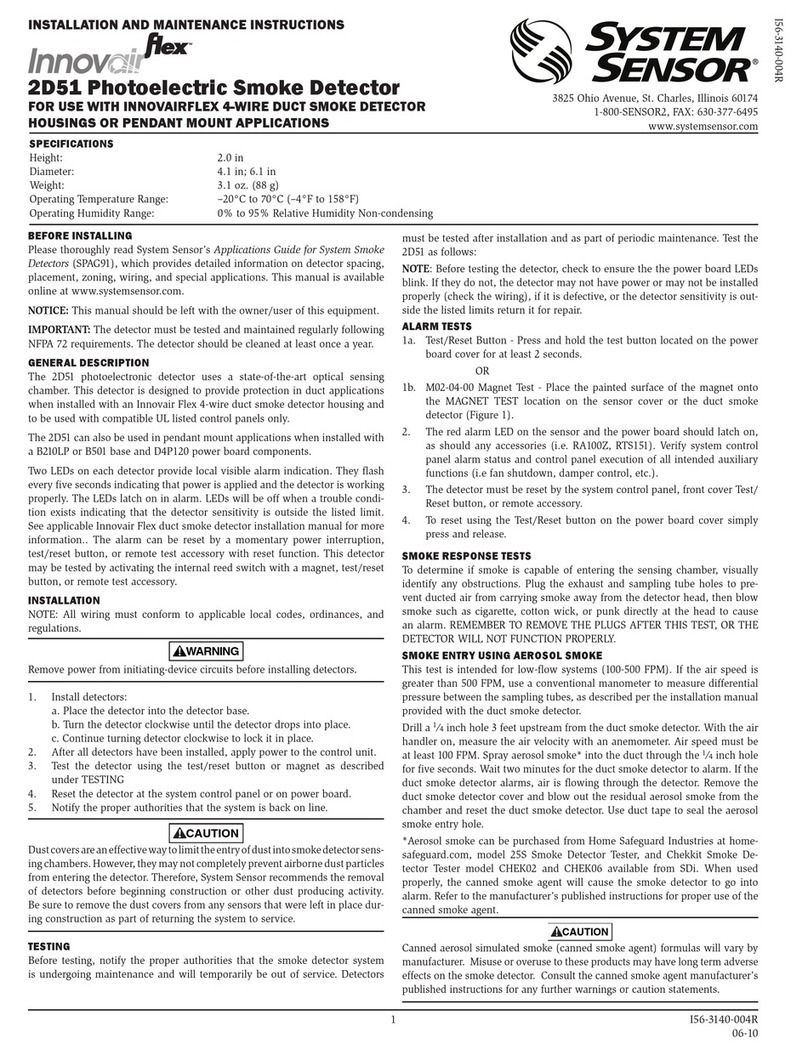

FIGURE 10. DNRE USING A TEST COIL

DCOIL

TEST COIL SCREW

[11] ADDITIONAL MODULE OPTION

The DNRE can also accommodate a relay or control module (sold separately)

within the power board side of the housing. The relay or control module must

be listed as compatible to the fire alarm control panel.

Physical Module Mounting

1) Remove the breakaway tabs at the four corners of the module

2) Locate the module at right most corner of the power board. The upper

left corner mounting hole of the module will align with a screw boss in

the housing.

3) Install a M4X0.7, 9.5 mm long thread forming screw at the screw boss location

Note: See the corresponding module Installation Instructions for general

description, control panel compatibility, wiring and ratings.

SS-300-021 5 I56-3538-003R

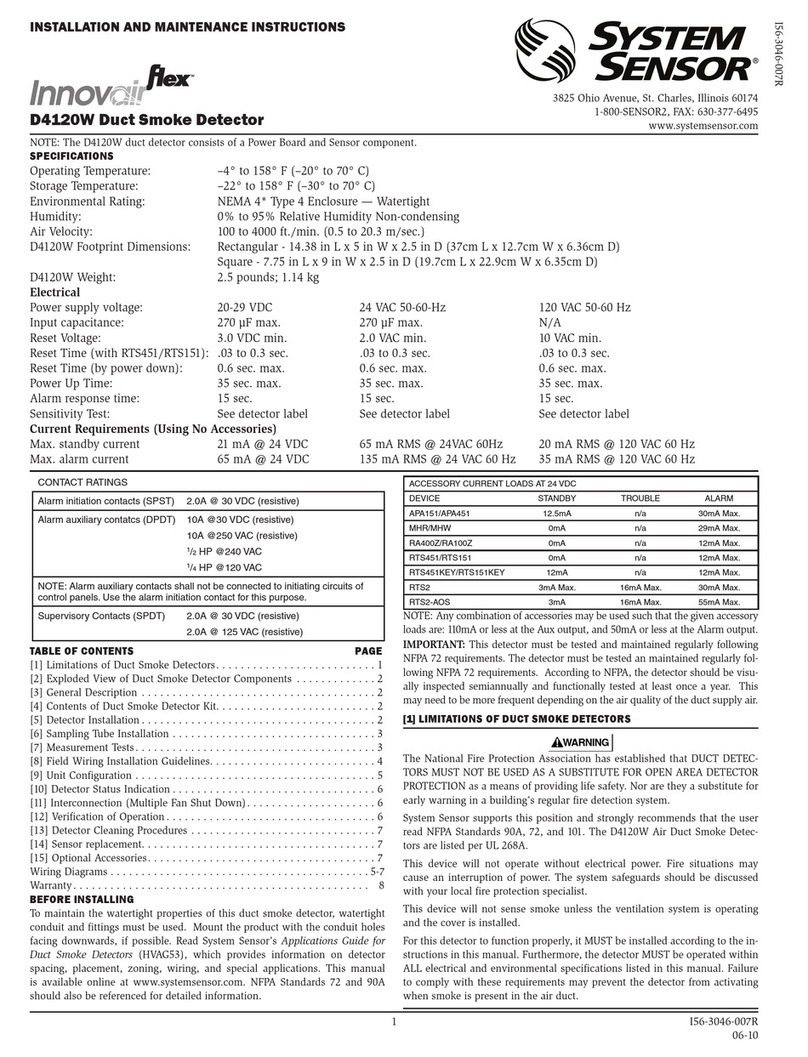

[6.2]LOW FLOW AIR FLOW TEST USING DWYER SERIES 607

DIFFERENTIAL PRESSURE TRANSMITTER

Verify the air speed of the duct using an anemometer. Air speed must be at

least 1.5 m/sec. Wire the transmitter as shown in Figure 5. Connect the leads

of the meter to either side of the 1000Ωresistor. Allow unit to warm up for

15 seconds. With both HIGH and LOW pressure ports open to ambient air,

measure and record the voltage drop across the 1000Ωresistor (measurement

1), 4.00 volts is typical. Using flexible tubing and rubber stoppers, connect the

HIGH side of the transmitter to the sampling tube of the duct smoke detec-

tor housing, and the LOW side of the transmitter to the exhaust tube of the

duct smoke detector housing. Measure and record the voltage drop across the

1000Ωresistor (measurement 2). Subtract the voltage recorded in measure-

ment 1 from the voltage recorded in measurement 2. If the difference is greater

than 0.15 volts, there is enough air flow through the duct smoke detector for

proper operation.

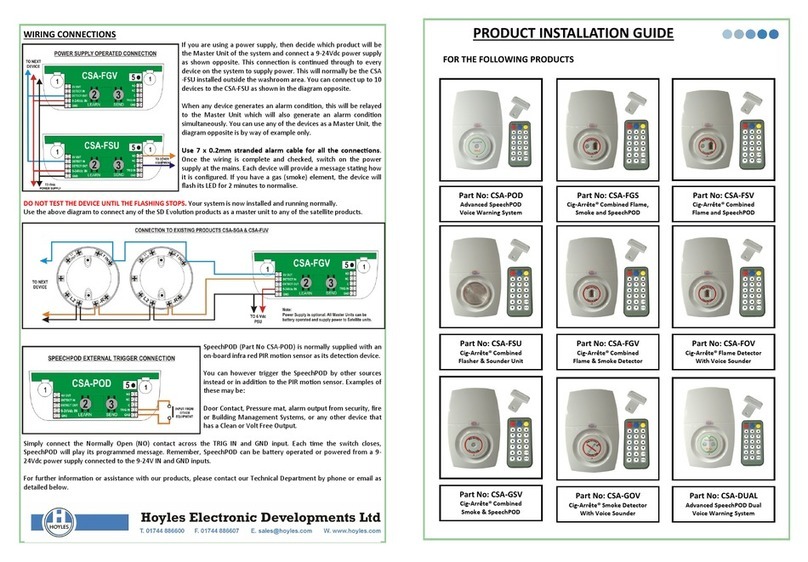

[7]FIELD WIRING; INSTALLATION GUIDELINES

All wiring must be installed in compliance with local wiring regulations.

Proper wire gauges should be used. The conductors used to connect smoke

detectors to control panels and accessory devices should be color-coded to

prevent wiring mistakes. Improper connections can prevent a system from

responding properly in the event of a fire.

For signal wiring (the wiring between detectors or from detector to auxiliary

devices), it is usually recommended that single conductor wire be no smaller

than 18 gauge. The duct smoke detector terminals accommodate wire sizes up

to 12 gauge. Flexible conduit is recommended for the last 30 cm of conduit;

solid conduit connections may be used if desired.

Duct smoke detectors and alarm system control panels have specifications for

Signaling Line Circuit (SLC) wiring. Consult the control panel manufacturer’s

specifications for wiring requirements before wiring the detector loop.

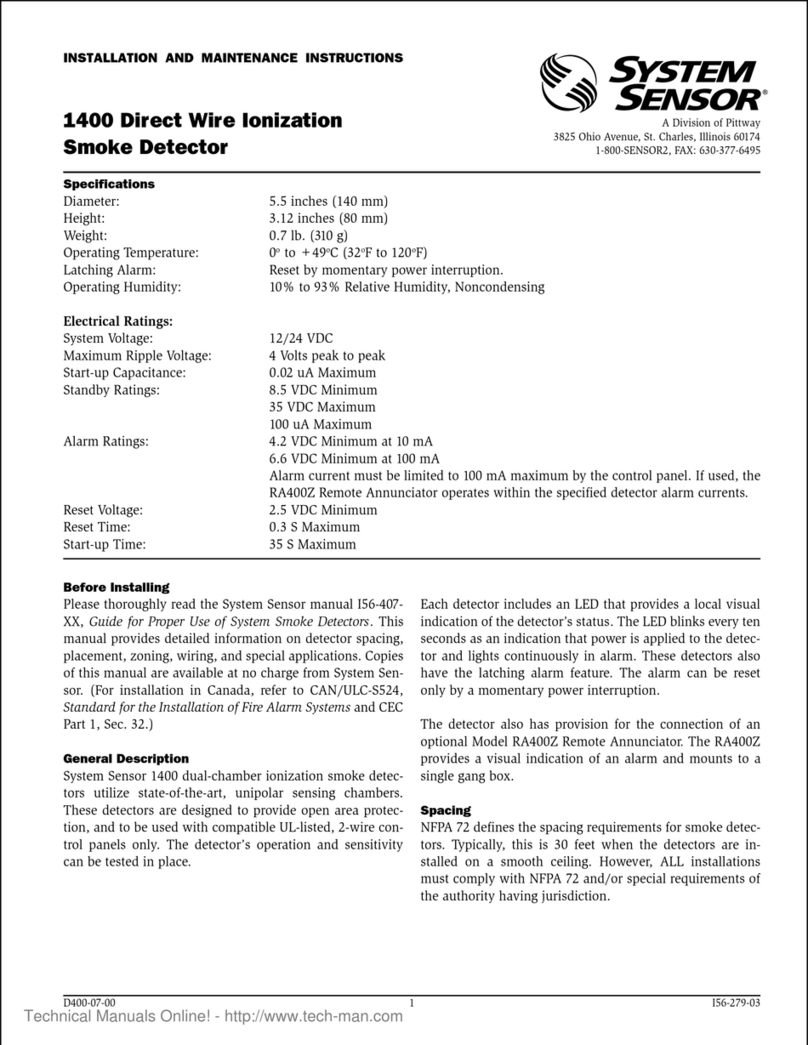

[7.1]WIRING INSTRUCTIONS

Disconnect power from the communication line before installing the DNRE

duct smoke detector.

The DNRE detectors are designed for easy wiring. The housing provides a ter-

minal strip with clamping plates. Wiring connections are made by sliding the

bare end under the plate, and tightening the clamping plate screw. See Figure

6on below for system wiring.

[7.2] SET THE ADDRESS

Set the desired address on the sensor head code wheel switches. on the back

of the sensor head.

SS-300-021 4 I56-3538-003R

FIGURE 6. SYSTEM WIRING DIAGRAM FOR DNRE:

HO119-04

HO112-03

Two LEDs on the sensor are controlled by the panel to indicate sensor

status. Coded signals, transmitted from the panel, can cause the LEDs

to blink, latch on, or latch off. Refer to the control panel technical docu-

mentation for sensor LED operation and expected delay to alarm.

[8.4.2] THE DETECTOR MUST BE RESET BY THE SYSTEM CONTROL PANEL

[8.4.3]SMOKE ENTRY TEST USING AEROSOL SMOKE

This test is intended for low-flow systems (1.5-254 m/sec). If the air speed is

greater than 2.54 m/sec, use a conventional manometer to measure differen-

tial pressure between the sampling tubes, as described under Measurement

Tests on Page 3.

Drill a .63 cm hole 91.4 cm upstream from the duct smoke detector. With the

air handler on, measure the air velocity with an anemometer. Air speed must

be at least 1.5 m/sec. Spray aerosol smoke into the duct through the .63 cm-

hole for five seconds. Wait two minutes for the duct smoke detector to alarm.

If the duct smoke detector alarms, air is flowing through the detector. Remove

the duct smoke detector cover and blow out the residual aerosol smoke from

the chamber and reset the duct smoke detector at the panel. Use duct tape to

seal the aerosol smoke entry hole. Remember to replace the cover after the test

or the detector will not function properly.

Canned aerosol simulated smoke (canned smoke agent) formulas will vary by

manufacturer. Misuse or overuse to these products may have long term adverse

effects on the smoke detector. Consult the canned smoke agent manufacturer’s

published instructions for any further warnings or caution statements.

[9]DETECTOR CLEANING PROCEDURES

Notify the proper authorities that the smoke detector system is undergoing

maintenance, and that the system will temporarily be out of service. Disable

the zone or system undergoing maintenance to prevent unwanted alarms and

possible dispatch of the fire department.

[9.1]DETECTOR SENSOR

1. Remove the sensor to be cleaned from the system.

2. Refer to the relevant detector installation manual for cleaning instructions.

3. Reinstall the detector.

[9.2]REINSTALLATION

1. Reinstall the detector in its housing.

2. Restore system power.

3. Perform Detector Check.

4. Notify the proper authorities testing has been completed and the smoke

detector system is back in operation.

[10]SENSOR REPLACEMENT

1. Remove the sensor head by rotating counterclockwise.

2. Pull gently to remove it.

3. To replace the sensor head, align the mounting features and rotate clock-

wise into place.

[11] OPTIONAL ACCESSORIES

Optional accessories include RA400Z/RA100Z, RTS451/RTS151 and

RTS451KEY/RTS151KEY and 6500RTS-KEY.

NOTE: Ensure blue wire always remains connected to RA+ terminal.

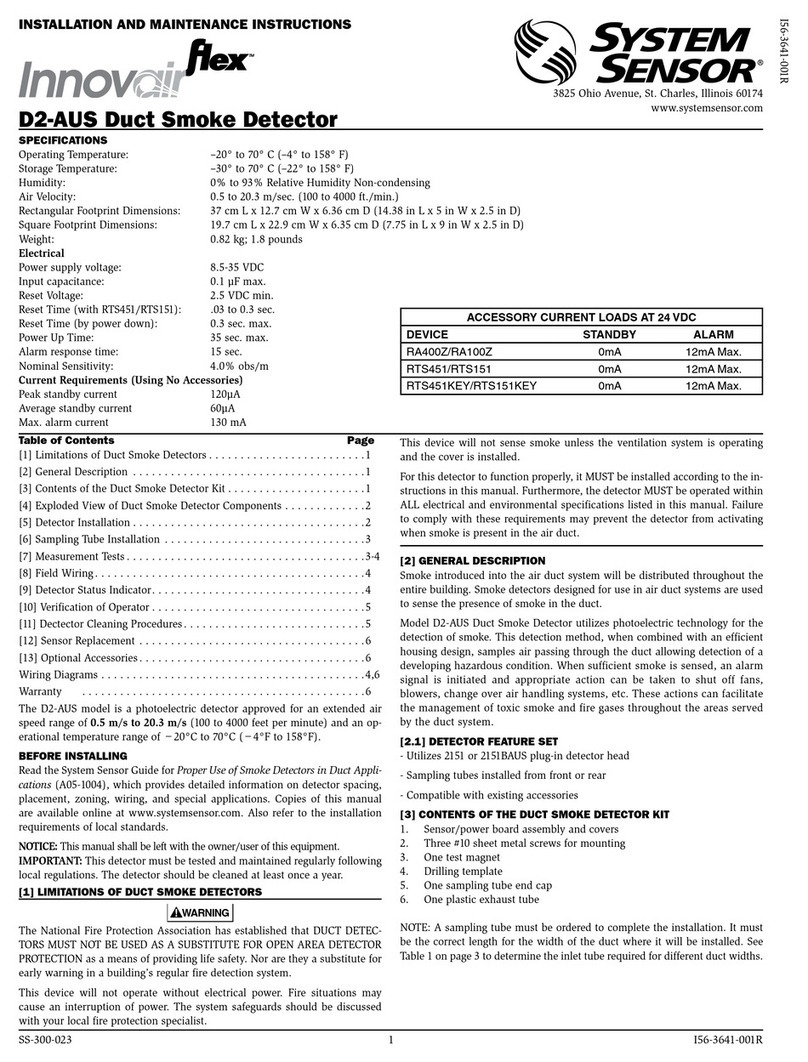

FIGURE 8. WIRING DIAGRAM FOR DNRE TO RA400Z/RA100Z:

(+)

(-)

RA400Z/RA100Z

– RA

REMOTE ALARM LED

OPTION 1 PER UNIT

H0570-03

Note: If using a RA400Z, the tab should be broken for use with the intelli-

gent duct smoke detector. If using RA100Z, ensure that jumper is removed.

The RTS451/RTS151/RTS451KEY/RTS151KEY Remote Test Station facilitates

test of the alarm capability of the duct smoke detector. These accessories pro-

vide the stimulus to initiate an alarm condition at the detector. The DNRE duct

smoke detector must be reset by the system control panel.

Note: Some panels support extended addressing. In order to set the sensor

above the address number 99 on compatible systems, carefully remove the

stop on the left hand rotary switch with pliers as shown in Figure 7.

NOTE: Verify sensor cover gasket is properly seated on cover prior to cover

installation

[8] VERIFICATION OF OPERATION

[8.1]INSTALL THE COVER

Install the covers making sure that the cover fits into the base groove. Tighten

the seven screws that are captured in the covers. Note that the cover must be

properly installed for proper operation of the sensor.

[8.2] POWER THE UNIT

Activate the communication line on terminals COM + and COM –.

[8.3] DETECTOR CHECK

Standby – If programmed by the system control panel, look for the presence of

the flashing LEDs through the transparent housing cover. The LED will flash

with each communication.

Trouble – If programmed by the system control panel and the detector LEDs

do not flash, then the detector lacks power (check wiring, missing or improp-

erly placed cover, panel programming, or power supply), the sensor head is

missing (replace), or the unit is defective (return for repair).

[8.4]DUCT SMOKE DETECTOR TEST & MAINTENANCE PROCEDURES

Test and maintain duct smoke detectors in accordance with local fire regula-

tions and practice. The tests contained in this manual were devised to assist

maintenance personnel in verification of proper detector operation.

Before conducting these tests, notify the proper authorities that the smoke

detection system will be temporarily out of service. Disable the zone or system

under test to prevent unwanted alarms.

[8.4.1]TEST THE UNIT

1. M02-04-00 Magnet Test – This sensor can be functionally tested with a

test magnet. The test magnet electronically simulates smoke in the sens-

ing chamber, testing the sensor electronics and connections to the control

panel.

2. Remote Test Accessory – The use of a remote accessory for visible indica-

tion of power and alarm is recommended.

Verify system control panel alarm status and control panel execution of all

intended auxiliary functions (i.e. fan shutdown, damper control, etc.).

H0561-01

EXTERNAL

(-) POWER (+)

SUPPLY

*

RTS451/151,

RTS451/151KEY

REMOTE TEST STATION

LED OPTION

1 PER UNIT

10mA CURRENT DRAW

TEST COIL OPTION

1 PER UNIT

95mA CURRENT DRAW

45

321

TEST COIL +

TEST COIL –

COMM +

OUT (CONV ONLY) +

COMM –

RA/RTS –

RA +

RTS +

NOTE: THE RTS451/151, RTS451/151KEY TEST COIL

CIRCUIT REQUIRES AN EXTERNAL 24 VDC POWER

SUPPLY.

NOTE: THE USE OF A REMOTE TEST STATION REQUIRES THE

INSTALLATION OF AN ACCESSORY COIL, PART NUMBER DCOIL. H0571-14

FIGURE 9. WIRING DIAGRAM FROM DNRE TO RTS451/RTS451KEY/

RTS151/RTS151KEY AND 6500RTS-KEY:

FIGURE 7. ROTARY ADDRESS SWITCHES