3

I

Systema Polska Sp. z o.o.

Lennox rev. 00ITIT20210827

SOMMARIO

1 GENERAL RULES..............................................................................................................................................................................................................5

1.1 EXPLOITATION ..........................................................................................................................................................................................................6

1.2 TERMS AND DEFINITIONS ......................................................................................................................................................................................7

2 FEATURES .......................................................................................................................................................................................................................8

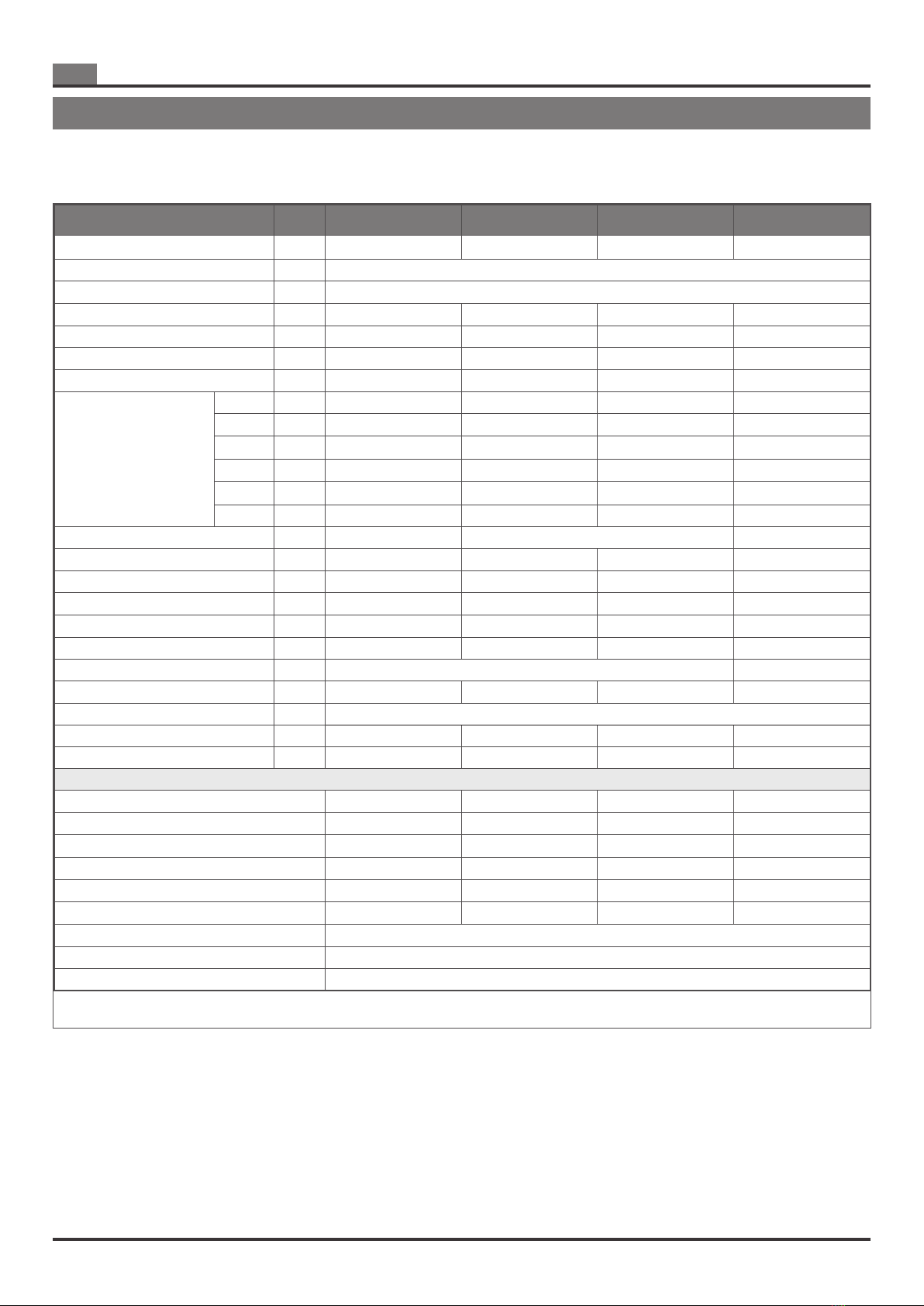

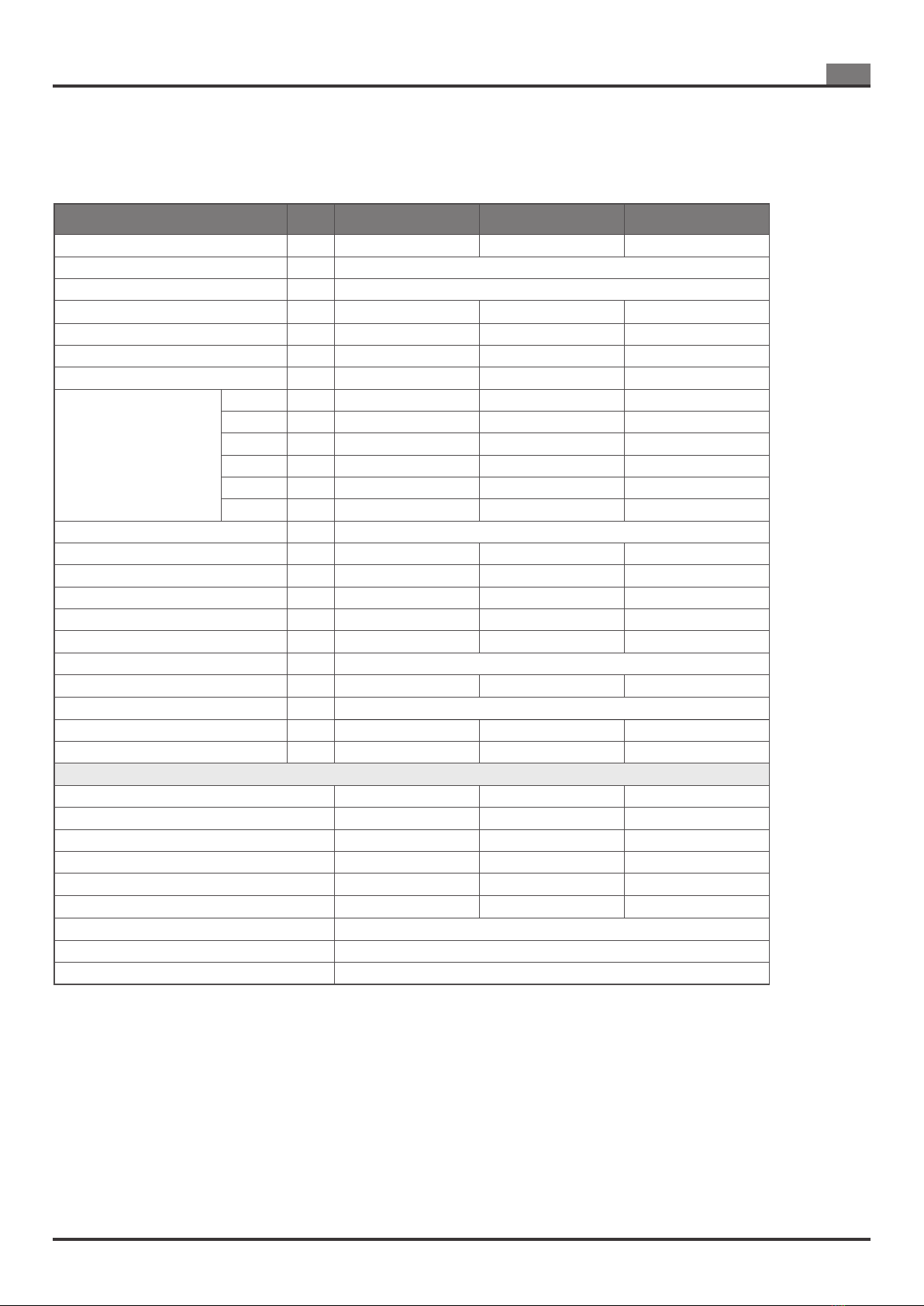

2.1 TECHNICAL DATA......................................................................................................................................................................................................8

2.2 IDENTIFICATION PLATE AND INFORMATION LABELS ....................................................................................................................................... 10

2.3 OVERALL DIMENSINS..............................................................................................................................................................................................12

2.4 COMPONENT ARRANGEMENT............................................................................................................................................................................... 13

2.5 LIST OF COMPONENTS ...........................................................................................................................................................................................14

2.6 BURNER...................................................................................................................................................................................................................... 16

2.6.1 VIP 1 HW................................................................................................................................................................................................................16

2.6.2 VIP 2 HW................................................................................................................................................................................................................17

2.6.3 VIP 3 HW a/b..........................................................................................................................................................................................................18

2.6.4 VIP 4 HW a.............................................................................................................................................................................................................19

2.6.5 VIP 4 HW b.............................................................................................................................................................................................................20

2.6.6 VIP 5 HW a.............................................................................................................................................................................................................21

3 WIRING .......................................................................................................................................................................................................................22

3.1 SCP674V130B1 CARD CONNECTIONS (MAIN BOARD)....................................................................................................................................... 24

3.2 SCP674V202MB SLAVE CARD CONNECTIONS.................................................................................................................................................... 26

4 OPERATION OF THE APPLIANCE .................................................................................................................................................................................. 27

4.1 CHARACTERISTICS OF THE COMMAND AND CONTROL BOARD SCP674V130B1........................................................................................ 27

4.2 SIGNALS ON THE DISPLAY..................................................................................................................................................................................... 28

4.3 MAINBOARD OPERATION ....................................................................................................................................................................................... 29

4.4 BURNER SHUTDOWN - COMBUSTION CHAMBER POST VENTILATION.........................................................................................................29

4.4.1 Burner shutdown due to the opening of a safety contact .......................................................................................................................................29

4.4.2 Burner shutdown due to burner fan speed exceeding............................................................................................................................................30

4.5 RESET OF BURNER..................................................................................................................................................................................................30

4.6 BURNER OPERATING PARAMETERS.................................................................................................................................................................... 30

4.7 SCP674V202MB SLAVE BOARD FEATURES ......................................................................................................................................................... 32

4.7.1 Main features..........................................................................................................................................................................................................32

4.7.2.1 Serial conguration of devices................................................................................................................................................................................33

4.7.2.2 Network / slave device addresses..........................................................................................................................................................................33

4.7.2.3 Exception codes .....................................................................................................................................................................................................33

4.7.2.4 COMMAND DESCRIPTION ...................................................................................................................................................................................34

4.8 SCP674V202MB SLAVE CARD PROGRAMMING .................................................................................................................................................. 35

4.8.1 SCP674V202MB card encoding for network operation..........................................................................................................................................35

4.8.2 DIP Switch Conguration 3.....................................................................................................................................................................................37

4.8.3 Conguration DIP Swicht 4.....................................................................................................................................................................................37

4.8.4 Menu SET-POINT: SEt ...........................................................................................................................................................................................37

4.8.5 FUNCTIONS menu: Fnc - burner RESET..............................................................................................................................................................38

4.8.6 Menu INFO: inFo....................................................................................................................................................................................................38

4.8.7 Menu ALARMS: ALSt ............................................................................................................................................................................................. 39

4.8.8 Menu PARAMETERS .............................................................................................................................................................................................39

4.8.9 Burner operation mode (PWM)...............................................................................................................................................................................40

5 GAS INSTALLATION.......................................................................................................................................................................................................... 42

5.1 CONNECTION OF THE APPLIANCE ....................................................................................................................................................................... 42

6 INSTALLATION...................................................................................................................................................................................................................45

6.1 PRELIMINARY UNLOADING OPERATIONS........................................................................................................................................................... 45

6.1.1 Packaging...............................................................................................................................................................................................................45

6.1.2 Packaging dimensions............................................................................................................................................................................................46

6.1.3 Handling with forklift ...............................................................................................................................................................................................46

6.1.4 Exchanger handling with eyebolts..........................................................................................................................................................................47

6.2 CONDENSATE DRAIN...............................................................................................................................................................................................48

6.2.1 Condensate drain connection.................................................................................................................................................................................48

6.2.2 Condensate stagnation in the exchanger...............................................................................................................................................................49

6.2.3 Frost protection.......................................................................................................................................................................................................49

6.2.4 Discharge into the drainage system .......................................................................................................................................................................49

6.3 EXHAUST DUCTS...................................................................................................................................................................................................... 49

6.4 APPLICATION IN AIR CONDITIONING SYSTEMS WITH REFRIGERANT GAS.................................................................................................51

6.5 CONDITIONS INSTALLING THE APPLIANCE IN AN EXTERNAL HOUSING AS AIR HANDLING UNIT..........................................................52

7 TESTING AND START-UP OF THE SYSTEM.................................................................................................................................................................. 53

7.1 DRY TEST (WITHOUT FUEL GAS) ..........................................................................................................................................................................53

7.2 PRELIMINARY OPERATIONS ..................................................................................................................................................................................53

7.3 STARTING UP THE APPLIANCE..............................................................................................................................................................................54

7.4 ADJUSTMENTS ......................................................................................................................................................................................................... 54

7.4.1 Gas unit with gas valves VR4205VE5002B and VK4415V1002B.......................................................................................................................... 55

7.4.2 Gas unit with gas valve VR415VE5024..................................................................................................................................................................56

7.5 POSITION OF ELECTRODES .................................................................................................................................................................................. 57

8 MAINTENANCE ..................................................................................................................................................................................................................58

8.1 FUEL CHANGE...........................................................................................................................................................................................................60

8.1.1 Replacement of the Venturi for gas valve VK4205VE5002B..................................................................................................................................................61

8.1.2 Pre-settings of gas valve VK4205VE5002B after gas type change. ......................................................................................................................................62

8.1.3 Replacement of the Venturi for gas valve VK4415V1002B ................................................................................................................................................... 63

8.1.4 Pre-settings of gas valve VK4415V1002B after gas type change..........................................................................................................................................64

8.1.5 Replacement of the Venturi for gas valve VR415/ VR420 ..................................................................................................................................................... 65

8.1.6 Pre-settings of gas valve VR415/VR420 after gas type change. ...........................................................................................................................................66

8.2 FAULTS AND REMEDIES..........................................................................................................................................................................................67