6

INTRODUCTION

About This Manual

This manual includes a Safety Summary, Operating Procedures, Machine Preparation, Maintenance Instructions and

Troubleshooting Procedures for transmission fluid exchanging. Anyone intending to use this machine should

become familiar with all the information included in this manual (especially the Safety Summary) before attempting

to use the Transmission Fluid Exchanger. In order to properly perform a complete transmission fluid exchange,

follow all procedures in the order presented. Please take the time to study this manual before operating the

machine. Then keep this manual close at hand for future reference.

The T-TECH Process

Heat is the enemy of transmission fluid. Transmission fluid is a combination of light base oils with an extensive

additive package to control foaming, slip, lubrication, etc. Heat attacks the additive package and oxidizes or burns

it away, leaving you with only the base oils.

In order to slow the oxidation of the additive package, the vehicle manufacturers have designed an oil cooler,

usually in the radiator, that passes all of the transmission fluid through it.

T-TECH uses a patented process of harnessing the pump in the vehicle’s transmission to control the flow of fluid.

This process captures the fluid coming out of the transmission and automatically directs it into the bottom of the

T-TECH cylinder. The used ATF flowing into the bottom of the cylinder pushes against the separating piston and

directs new fluid out the top of the cylinder and back into the vehicle.

The patented T-TECH system makes it IMPOSSIBLE TO HARM A VEHICLE’S TRANSMISSION. The T-TECH

process operates exclusively on the transmission pump pressure, which essentially eliminates the possibility of

over-pressure, under-pressure, overfill or underfill.

T-TECH Fluid Exchange is the preferred method of automatic transmission service because it is designed to offer

the safest and most complete exchange of fluid in the transmission, torque converter, lines and cooler.

The need for a safe and thorough exchange of used ATF has increased as the life expectancy of vehicles increases,

the demands placed on these vehicles grows and the cost of repair rises. Today, nearly every vehicle has an OEM-

recommended service for automatic transmissions.

The original pan drop method of service only captured 30% - 40% of the vehicle’s used ATF. Other mechanical

exchange machines force fluid into the vehicle under pressure and can damage the seals inside a transmission.

Discover why vehicle owners throughout North America specify T-TECH when asking for ATF service

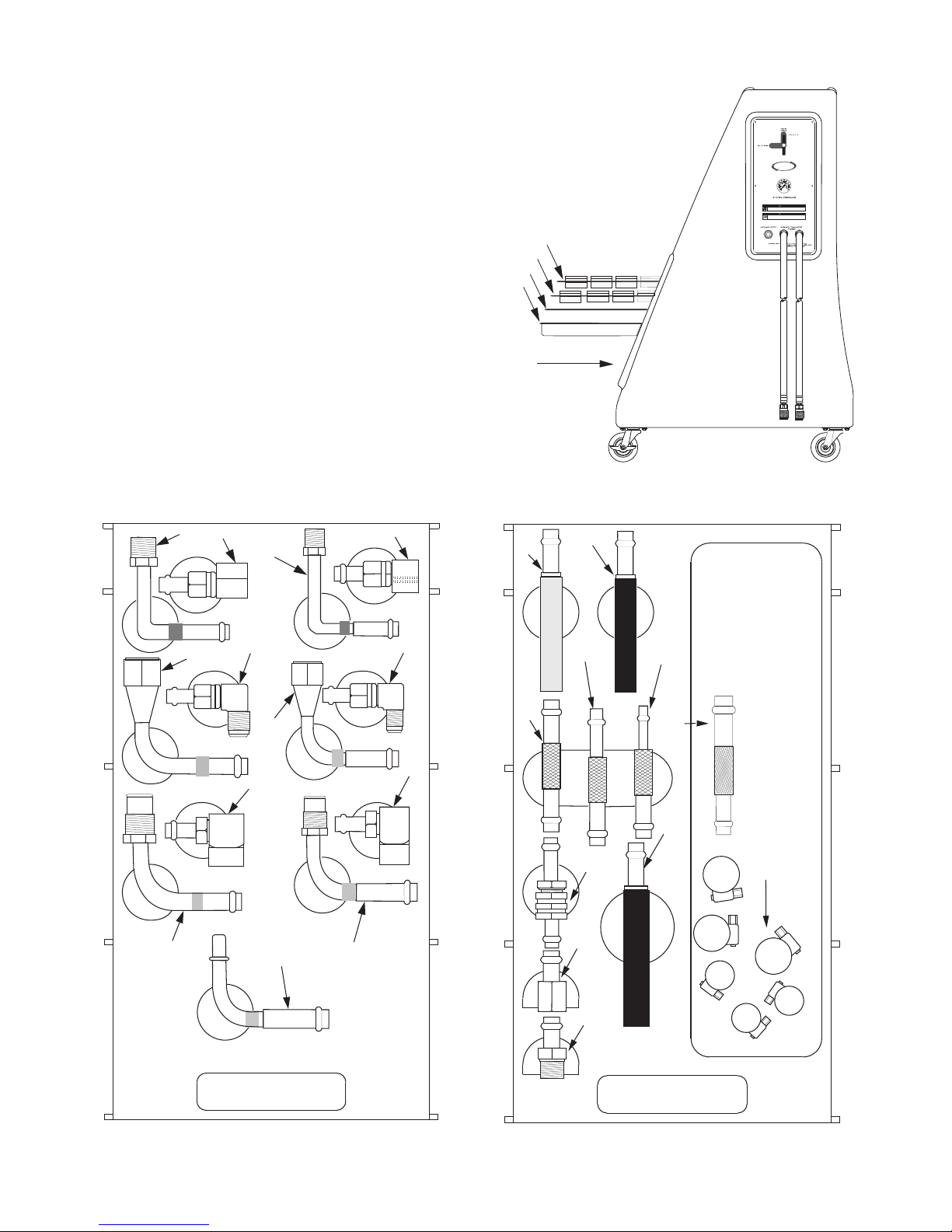

T-TECH Specifications

Max Pressure: 85 psi, 583 kPa

Weight (approx.): 96 lbs. (43.54 kg)

Depth: 32.5 in. (0.83 m)

Width: 21.5 in. (0.55 m)

Height: 51.5 in. (1.31 m)

Patents: 5,318,080, Re. 38,650; 6,082,416; 6,267,160; 6,330,934

Note: Do not leave your T-TECH in direct sunlight in extremely hot temperatures (>90ºF) for extended periods.

Such exposure can have detrimental effects on the case.