DXF Getting Started Guide Page 10

Table of Contents

Introduction................................................................................................................................................. 3

Important: TA Instruments Manual Supplement ................................................................................... 3

Notes, Cautions, and Warnings .............................................................................................................. 4

Regulatory Compliance .......................................................................................................................... 4

Safety Standards .............................................................................................................................. 4

Electromagnetic Compatibility Standards ....................................................................................... 5

Supplier’s Declaration of Conformity .................................................................................................... 6

Safety ...................................................................................................................................................... 6

Instrument Symbols ......................................................................................................................... 6

Warnings .......................................................................................................................................... 7

Electrical Safety ............................................................................................................................... 7

Liquid Nitrogen Safety .................................................................................................................... 7

Thermal Safety ................................................................................................................................ 8

Chemical Safety ............................................................................................................................... 8

Lifting the Instrument ...................................................................................................................... 9

Table of Contents...................................................................................................................................... 10

Chapter 1: Introducing the Discovery Xenon Flash.............................................................................. 12

Overview ..................................................................................................................................................... 12

DXF System Components .......................................................................................................................... 13

Pulse Source Module ............................................................................................................................ 13

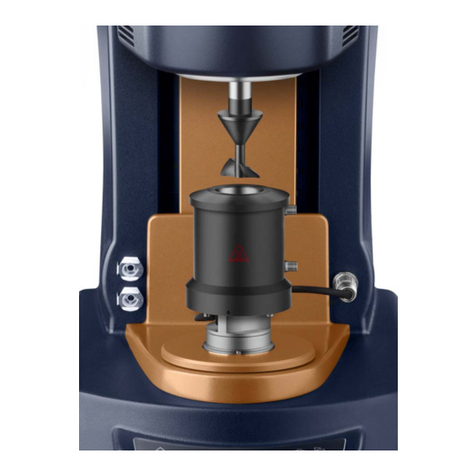

Environmental Modules and Detector Assembly ................................................................................ 16

Instrument Specifications ........................................................................................................................... 17

Chapter 2: Installing the DXF System.................................................................................................... 18

Unpacking/Repacking ................................................................................................................................. 18

Installing the System ................................................................................................................................... 18

Inspecting the System .......................................................................................................................... 18

Choosing a Location ............................................................................................................................ 19

In .................................................................................................................................................... 19

On .................................................................................................................................................. 19

Near ............................................................................................................................................... 19

Away from ..................................................................................................................................... 19

Moving the Instrument ......................................................................................................................... 20

Connecting the Environmental Module to the Pulse Source Module .................................................. 22

DXF Back Panel ............................................................................................................................ 23

Connecting the Environmental Module to the Pulse Source ......................................................... 26

Connecting the Detector Cable to the Detector Head Assembly ................................................... 27

Setting Up System Communication with the Controller (Computer) .................................................. 27

Connecting the Utilities ........................................................................................................................ 28

Connecting the Power .................................................................................................................... 28

Setting Up the Vacuum System ..................................................................................................... 28

Connecting Cryogenic Cooling and Purge Gas Lines ................................................................... 29

Installing the Tray ................................................................................................................................ 29

Calibrating the Tray Position ............................................................................................................... 31

Verifying the Tray Position Calibration ........................................................................................ 32

Installing the Pins ................................................................................................................................. 33