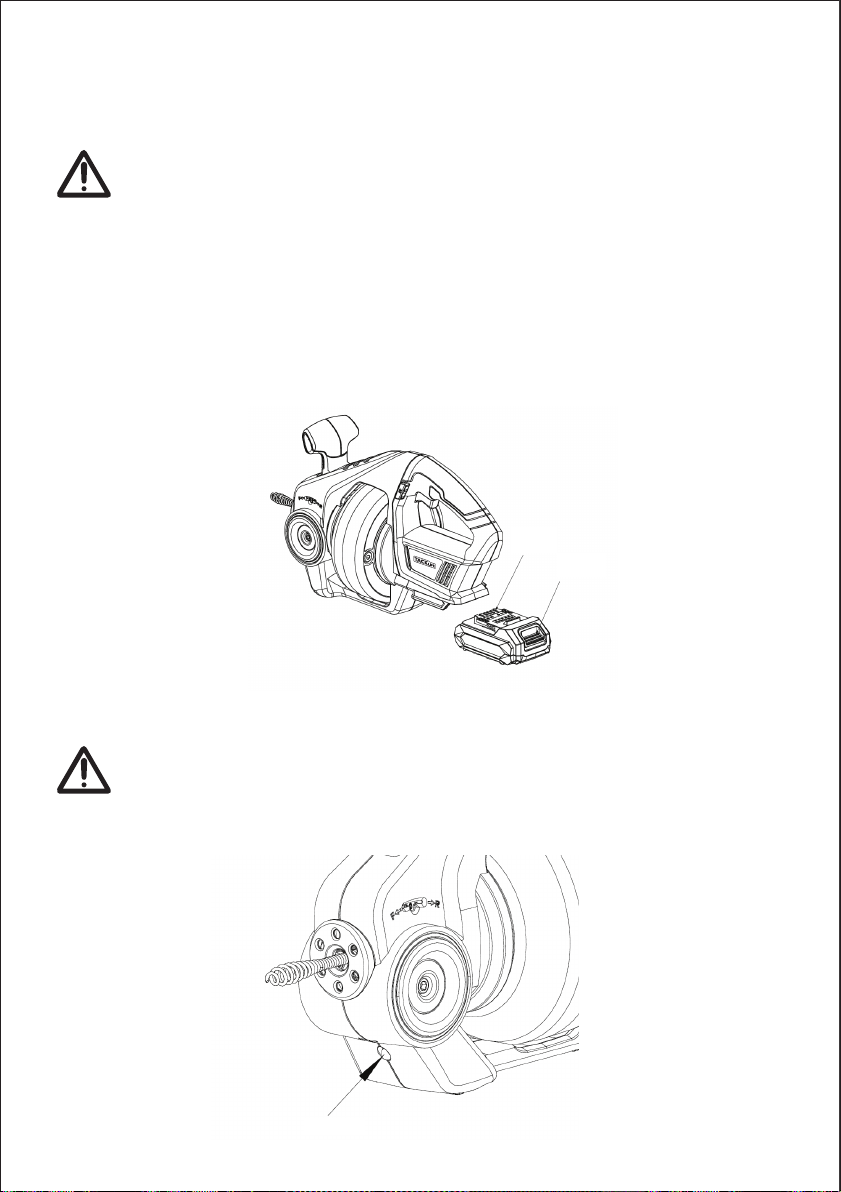

When the battery pack is inserted in or taken out, please be sure to switch off the tool power.

When the battery pack is dismantled, press the button at the end of the battery pack and pull it out

from the tool.

When inserting the battery pack, align the reed on the battery pack with the groove on the housing

and push the slide in place. Then, be sure to insert it to the bottom until there is a clicking sound;

otherwise, the battery pack will fall off from the battery pack, which might cause injury to the operator

or the others.

Do not push too hard when inserting the batch pack. If the battery pack doesn’t slide smoothly, it may

be caused by improper insertion.

NOTICE

WARNING

CAUTION

Operating Instructions:

Control

Notice: Before using the machine, you must be familiar with the functions and be proficient in operating

it.

Installation and Disassembly of Battery Pack

1.

2.

3.

4.

Switch variable speed

Control the speed between 0~560RPM, exert pressure on the switch: the greater the pressure, the higher

the speed.

Flood light

Pull the trigger to switch on the light. When the trigger is pulled, the light is on; when the trigger is released,

the light is off. (Figure3)

Please use clean cloth to wipe the lamp holder in case of scratching; otherwise it will reduce luminance.

Safety Identifier

Some safety identification symbols and professional vocabulary are used to express the important

safety precautions and safety practices in this manual and the product. This section is intended to help

readers better understand these symbols and terms.

Basic Safety Code

Warning!

Please read all safety precautions and safety instructions carefully. Failure to comply with these safety

instructions may result in electric shock

Please keep these safety precautions and safety instructions for future reference.

Power tool means two types of equipment: one with power cord and directly powered by external power

supply and another without power cord and powered by battery.

Work Area Safety

1.

2.

3.

Electrical Safety

1.

2.

3.

Keep the workplace clean and tidy and with sufficient lighting. Chaos and darkness of the environment

are likely to cause safety accidents.

Do not operate the machine in hazardous environments that is flammable and explosive, such as

flammable and explosive liquids, gases or dust. Power tools are prone to generate sparks that can

ignite these dusts or gases.

When operating the machine, keep unrelated personnel (including children, bystanders, non-staff,

etc.) away from the work site. Distraction could easily lead to the occurrence of safety accidents.

The power tool plug should match the socket. Do not change the plug at all times. Do not connect

the adapter of the plug of grounded power tool to be used together. Not changing the plug and

matching the socket will reduce the occurrence of electric shock.

Do not place the power tools in rain or in a humid environment. Liquid entering the power tool will

increase the risk of electric shock.

Do not damage the power cord. Do not use the power cord to drag and pull the power tool. Keep the

power cord away from hot, oil, sharp edges or moving objects. Damage to the power cord or other

objects twined can increase the risk of electric shock.

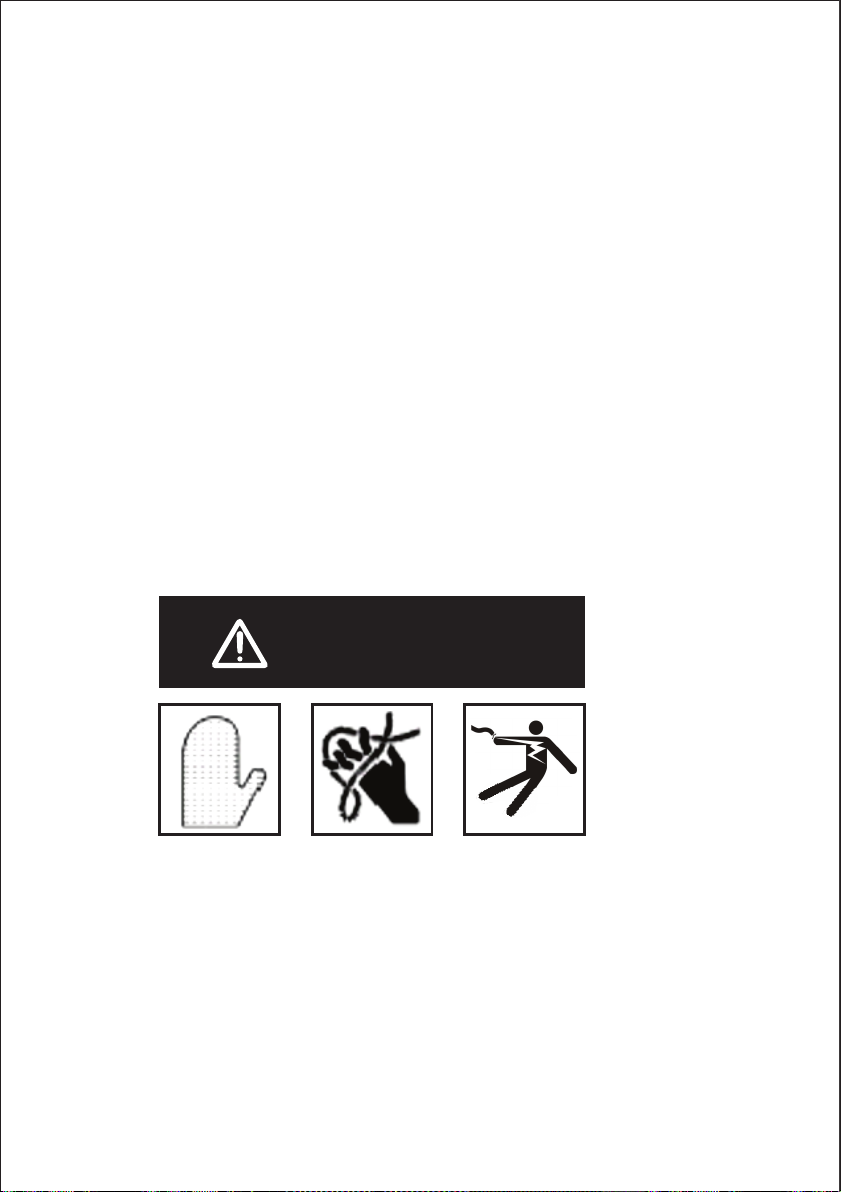

This is the safety warning symbol - used as a warning of some potential personal injury

hazards. Follow the guidance of safety information to avoid possible injury accidents, or

even death.

Danger warning symbol - indicating that there are dangerous situations around which, if not

avoided, could result in death and serious injury accidents.

Warning symbol-indicating dangerous situations which, if not avoided, could result in death

or serious injury accidents.

Caution symbol- indicating dangerous situations which, if not avoided, could result in minor

or moderate injury accidents.

Notice symbols - indicating safety information related to the protection of the property,

which means that the user must read the operation manual carefully before using the tool,

since important safety precautions and proper method of application are introduced in the

operation manual.

This symbol indicates that you must always wear safety cover and safety goggles and pay

attention when operating the tools.

The symbol indicates that there are certain risks that the hand, finger or other parts of the

body may be bruised.

This symbol indicates the risk of electric shock.

4.

5.

Personal Safety

1.

2.

3.

4.

Use and Maintenance of Battery

1.

2.

3.

4.

Important safety instructions for battery pack

1.

2.

3.

4.

5.

6.

(1)

(2)

(3)

7.

8.

9.

Please keep this instruction

Prompt for Maintaining Maximum Battery Pack Service Life

1.

When power tools are used outdoor, please use suitable outdoor special extension cord, which

might reduce risk of electric shock.

Avoid using the power tools in a humid environment. Please use the GFCI protection device, which

can reduce the risk of electric shock.

When using the power tools, keep a clear head and concentrate.

Do not use power tools in the event of fatigue or affected by medicine, alcohol or drugs. Careless

operation will lead to serious injury accidents.

Use personal protective equipment properly and always wear safety goggles. Personal protective

equipment includes dust masks, non-slip safety shoes, hard mats or thermal protection devices.

Appropriate use of the protective equipment will reduce the personal injury accidents.

Keep the body in balance and do not lose balance when operating the machine. This will help you

better control the tools in the case of accidents.

In prevention of unexpected startup, when connected to power or battery.

Please use designated charger specified by the manufacturer only. It might cause fire when one type

of charger is used for another type of battery pack.

Electric power tool can apply the designated battery packs, otherwise application of other battery

packs might cause personal injuries or fire.

When battery pack is not used, please place it away from metallic objects like paper clips, coins,

keys, nails, screws or other small metal materials, which may form connection from one end to the

other, short circuit the battery terminal and cause burning or fire.

When overused, there may be liquid flowing out of the battery. Please avoid direct body contact. If

there is accidental contact with battery drain, please rinse with water. In case of eye exposure,

please see a doctor. Battery drain might cause allergic inflammation or burns.

Before use of battery pack, please review all relevant instructions and warning labels of the (1)

charger, (2)battery pack and products that (3) need to use battery pack.

Non-detachable battery pack.

If the working hours are too short, it shall immediately stop operation; otherwise, it may cause

overheating, burning or even exploding.

In case of eye exposure to electrolyte, rinse eyes with water immediately and ask for doctor’s advice,

otherwise, it might cause blindness.

When the battery pack is not used, be sure to use the battery cover to cover the battery pack

terminal.

Do not make the battery pack short circuited

Do not make any conductor contact the terminal of the battery pack

Do not place the battery pack in the containers with iron nails, coins and other metallic objects.

Do not place the battery pack in areas with water or may be affected by rain.

Battery short circuit will cause a huge current to pass and overheat, which might result in burning or

even accidents.

Do not place the host machine and battery pack in areas above 50°(122°F).

Even if the battery pack is seriously damaged or completely depleted, do not burn it, otherwise the

battery pack will be exploded in the fire.

Be careful not to cause falling off or collide with the battery pack.

Charge the battery pack before full discharge.

When the machine is found to be underpowered, be sure to stop operating the machine and charge

the battery pack.

2.

3.

4.

Service

Product repair service shall be only conducted by the qualified maintenance personnel with

accepted parts, so as to ensure use safety and correct maintenance of tools.

Product Safety Precautions

Warning!

This section is important safety information specific to the tool. Please read the specification

carefully before use, so as to reduce electric shock or serious injury accidents.

Please keep the safety instructions well!

Pipe Dredger Safety Guidelines

The operation manual contains some specific machine safety information and operating instructions to

prevent the following serious personal injuries:

●

●

●

Read and follow the safety labels on the machine and familiarize yourself with the positions and

functions of all controllers before using the machine.

Warning:

The flexible shaft may wrap or break the fingers and palms, or cause damage to other parts of

the body.

●

●

●

Machine safety:

1.

2.

3.

4.

Do not charge the charged battery pack. Overcharging will shorten the service life of the battery

pack.

Charge the battery pack with ambient temperature at 10°-40°(50°F-104°F), please cool down the

heated before charging.

When battery pack is not used for over six months, charge the ni-mh battery pack.

It will cause injury to fingers, hands, arms or other body parts if clothes or gloves are drawn into the

rotating parts.

It will cause electric shock or burn when contacting the motor or other electric components.

Eye injury caused by the flexible shafts, cables or flying debris.

Wear rubber gloves.

Wear protective goggles.

Make the machine close to the pipe inlet.

Do not use soft gloves or cloth to hold the rotating flexible shaft, which may cause serious injury if

twined in the flexible shaft.

Do not over-deliver the flexible shaft, excessive deliver due to blockage may cause the winding or

break off of flexible shaft and cause serious injury.

Keep the tool as close as possible to the pipe. When the tool is difficult to approach the pipe, use the

front guide tube. If the distance is too long, it may cause the winding or break off of flexible shaft.

Do not operate the machine while reversing (pressing the forward and reverse rotation button R).

Operating in the (R) state can cause damage to the flexible shaft. The button (R) is only used to exit

the flexible axis in case of blocking.

5.

6.

7.

8.

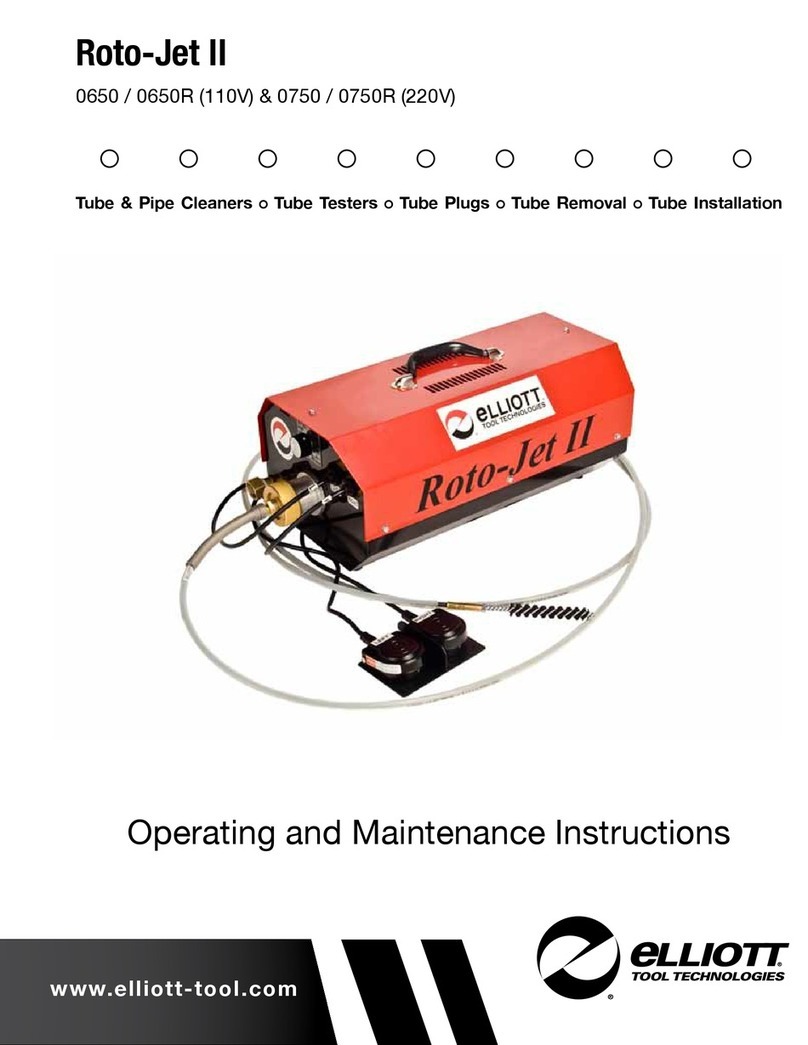

Product Overview, Specification and Standard Configuration

Product Overview

HGDDC1A is a handheld pipe dredger, which is used to dredge the 3/4” to 2” of the pipes such as:

kitchen pipes and bathroom pipes.

HGDDC1A dredger has an independent handle to operate the rolling jaw with automatic driving and

reversing mechanism that can achieve automatic advance and retraction of the flexible shaft to reduce

manual operations.

HGDDC1A Specification

Use the guide hose to prevent the flexible shaft from bringing foreign matter when jittering.

After using detergent in the pipe, avoid direct contact with skin or eyes. Some detergents can cause

severe burns.

The function of this tool is to clean and dredge the pipes. Please follow the instructions in the opera-

tion manual. Wrong use can cause injury.

The function of this tool is to clean and dredge the pipes. Please follow the instructions in the opera-

tion manual. Wrong use can cause injury.

Check before Operation

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

Notice: Please use the standard power cord.

When using the power tool outdoors, use extension cable marked with “W-A” or “W\” and the wire insulation

layer must be thick enough.

These cables are suitable for outdoor use and can reduce the occurrence of electric shock.

Make sure the battery pack is unplugged.

Check if the cable plug is damaged.

Check if the waterproof plug on the drum is installed and the wrench is removed.

Check if there are damaged machine parts that may pose a threat to your safety.

Lubricate the flexible shaft in according to the operation manual.

Selection of appropriate accessories for pipe dredge can improve the efficiency and quality of

dredging.

Before using, clean up the dirt on handle and the machine body.

Check if the flexible shaft is worn or damaged. In the cases of worn flat, corrosion and bending

deformation, please immediately replace the flexible shaft.

Check the workplace to ensure sufficient lighting, no flammable liquid, gas or dust. Check the

connection of cable and socket to ensure that the cable will not be damaged.

Do not place the side of the flexible shaft towards the operator or other people.

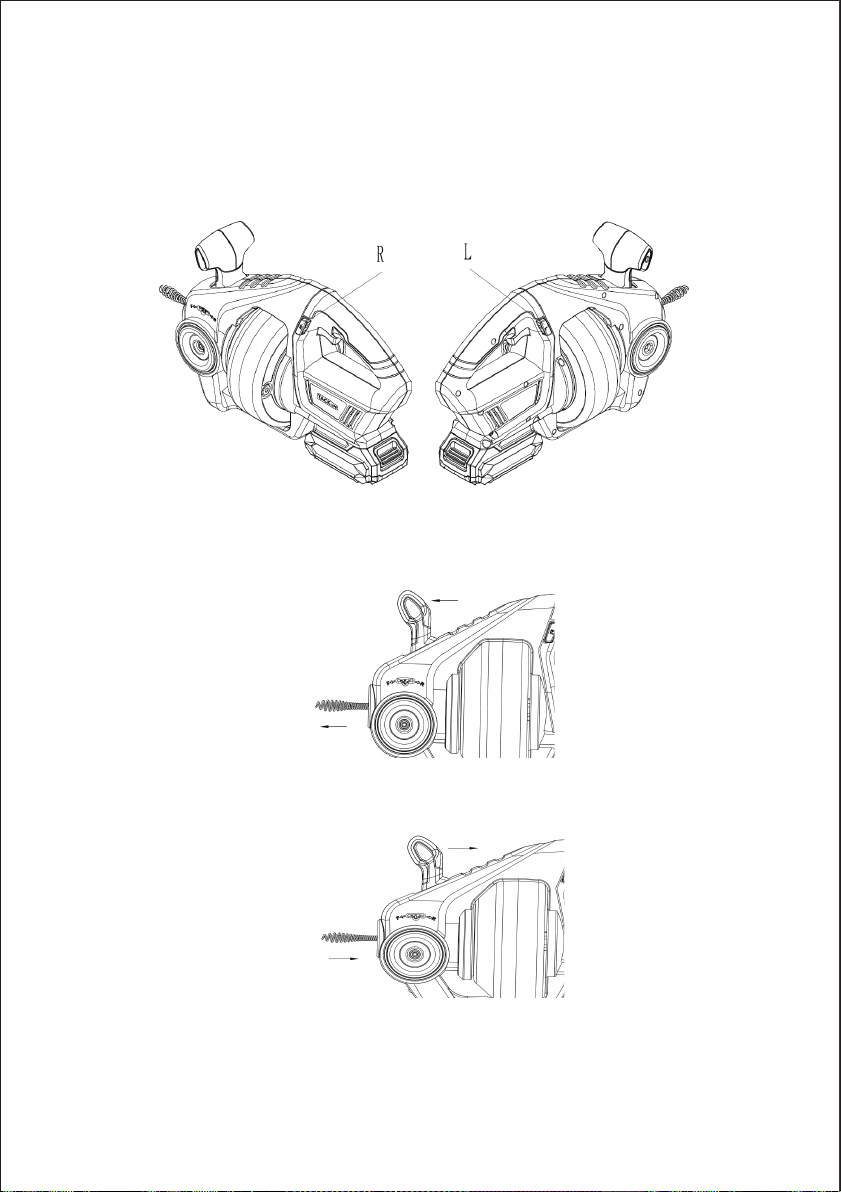

Switch forward and reverse rotation

This switch can control the steering of the flexible shaft: press the L for forward rotation and press the R for

reverse rotation, when the driving lever is in the middle and the trigger cannot be pulled

It is required to confirm the rotation direction before operation.

The forward and reverse rotation push button can be switched when the tool completely stops rotating.

When tools are not used, please be sure to switch the forward and reverse rotation push button in the

middle state in case of mis-operation.

Notice: The reverse rotation is only used to retract the flexible shaft in the trapped state (Fig.4).

Flexible shaft auto scaling

1.

1)

2)

Press the forward and reverse rotation button L:

Press the speed switch lightly, move the handle forward to the F position, and the flexible shaft will

be delivered forward (Fig. 5);

Press the speed switch lightly, pull the handle back to the R position, and the flexible shaft will retract

backwards (Fig. 6).

1.

Pipe dredge (before operation, be familiar with the automatic scaling operation of the flexible

shaft, otherwise it will lead to personal injury or damage to the tool)

1)

2)

3)

2.

1)

2)

Whether the pipe has been dredged or cannot be dredged, you need to rotate the locking ring

clockwise, loosen the jaw, and retract the flexible shaft by the automatic scaling function.

3.

4.

When the forward and reverse rotation button R is pressed, the flexible shaft stretches in the

opposite direction.

When the operating handle is in the O neutral position, the flexible shaft stops stretching no matter

in forward or reverse rotation (Fig. 7)

Please place the tool head at a distance of less than 150mm away from the pipe opening. If the

distance is too long, it will cause the flexible shaft to be twisted and knotted; and do not place the

tool head too close to the pipe, which is inconvenient to observe the condition of the flexible shaft

(Fig. 8).

Press the forward and reverse rotation button L, press the speed switch slightly, pull the handle

forward to the F position, and the flexible shaft will be delivered forward to start dredging; after

dredging the pipe, pull the handle back to the R position to retract the flexible shaft;

In the cases of blockage or blocked cornering of the flexible shaft, pull back the handle to retract for

a certain distance, and then pull forward to deliver again. Repeatedly move forward and backward

the operating handle to dredge the pipe and move through the corners. Do not force the delivery of

the flexible shaft, otherwise the flexible shaft will twist knotted or be broken and cause serious

injury;

If the blockage is too stubborn, apply the following two methods:

Rotate the locking ring counterclockwise to obtain a greater thrust. In this case, it is necessary

to lightly press the speed switch to closely observe the state of the flexible shaft. If the flexible

shaft is obstructed, twisted or knotted, release the speed switch immediately and stop the

rotation. Do not force the delivery of the flexible shaft;

Switch the operating handle in F and 0 positions, and dredge the pipe slowly according to the

actual situation.

If the flexible shaft is trapped in the pipe: that is, it cannot dredge or be retracted, press the

forward and reverse rotation button R, and pull the handle forward to retract the flexible shaft.

Notice: Situations of pipe blockage are varied, it is necessary to closely observe the situation of

the flexible shaft when using it. If it is distorted or blocked, stop the machine immediately, and

then take different operations according to the actual situation. If the pipe cannot be dredged,

please ask for professional for help. Do not force the operation and cause unnecessary troubles.

How to replace the flexible shaft

HGDDC1A pipe dredger provides a quick flexible shaft replacement device.

1.

2.

3.

4.

5.

Do not start the tool to retract the flexible shaft, because the exposed flexible shaft can lead to unpredict-

able personal injury, tool damage, damage to indoor objects, fire, electric shock and other dangerous

situations.

If the flexible shaft cannot be replaced normally, please send it to the designated service center for repair.

Storage and Maintenance of the Machine

Place the operating handle in the O position;

Take out the flexible shaft to expose the connector;

Unscrew the M4 set screws with an Allen wrench and remove the unwanted flexible shaft (Fig. 9);

Insert the new flexible shaft into the connector, align the screw holes, and tighten the M4 set

screws again;

Push the flexible shaft manually to the inside of the drum.

- 01 -

DANGER