.Fine-adjustment of discharge volume is per-

formed by the stroke adjustment dial. (See 10.

Setup Examples.)

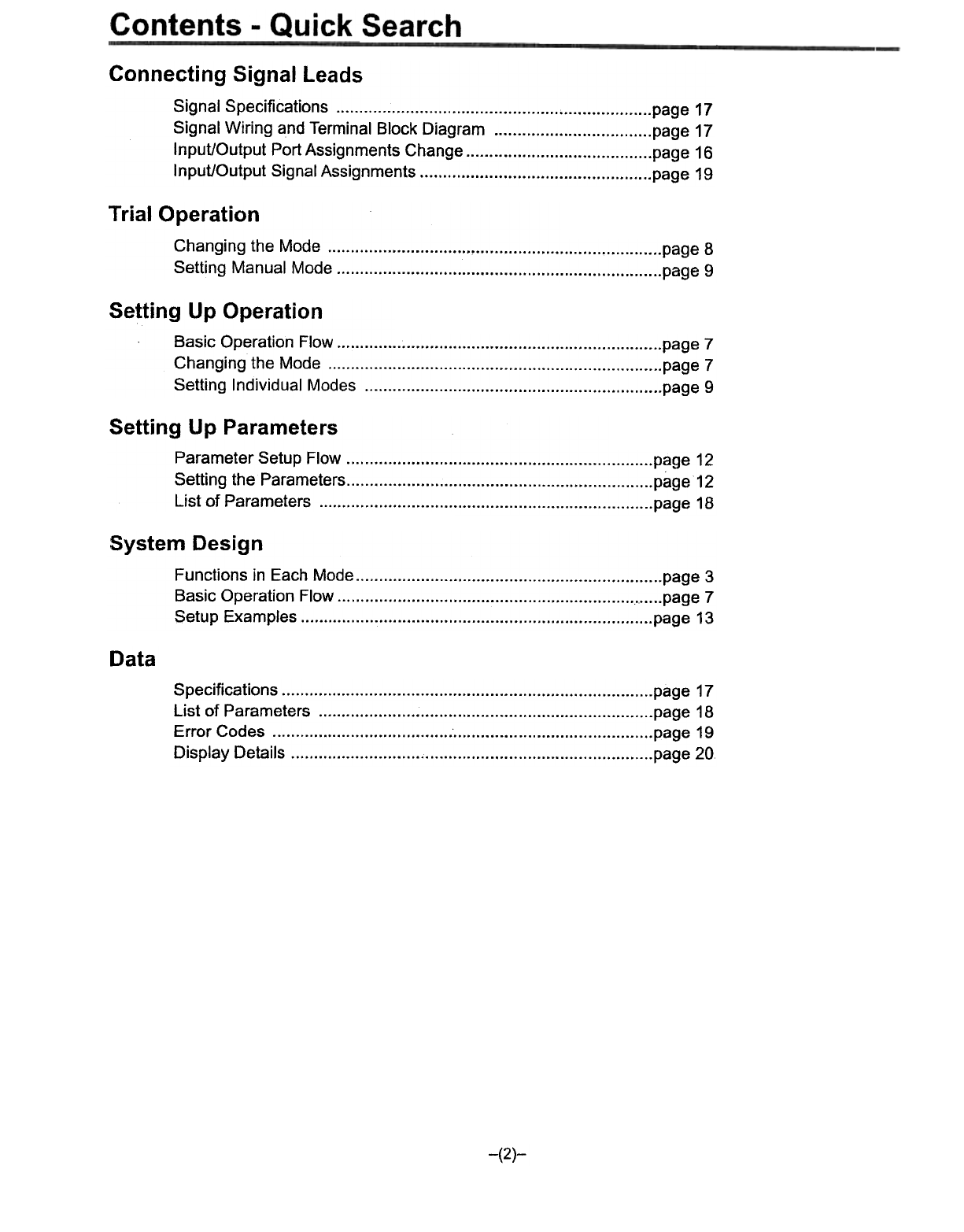

2. Purpose of use

.This mode is used for flowrate proportional injec-

tion, etc. The pump operates proportionally to the

number of input pulses from the outside.

.Used when there are a few number of pulses

from a flow meter or other instrument, and the

chemical injection amount is too small. (setting

in direction for increasing injection amount)

.Fine-adjustment of discharge volume is per-

formed by the stroke adjustment dial. (See 10.

Setup Examples.)

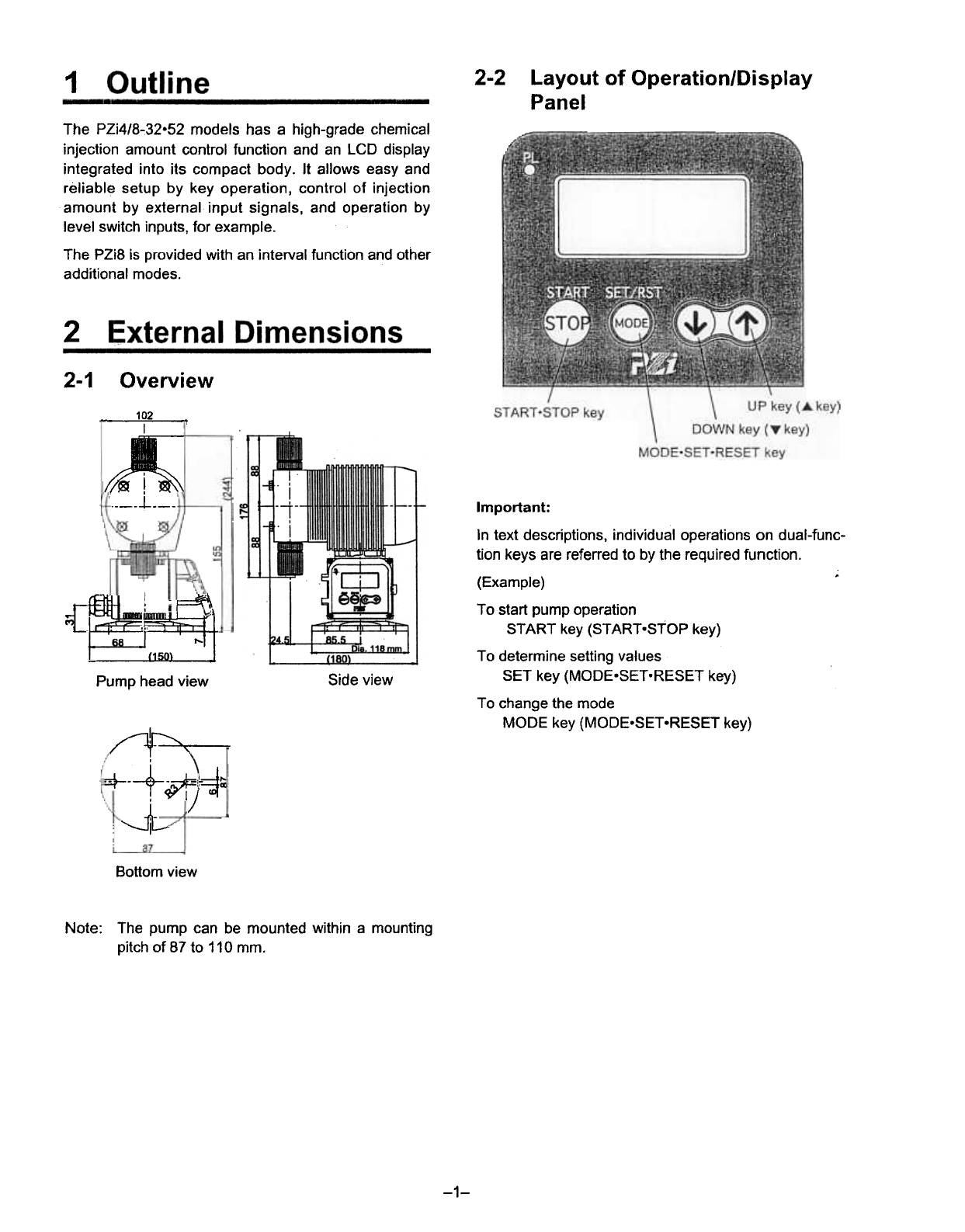

3.

LCD display

During a pump stoppageC

~~JTPI

DIY

During pump operation

[=~~~~ 3. LCD display

During setting

-I I I , .-

ISTP-,'9999:-

DI' i II I \

During a pump stoppage

Fp II

I lOUt 'J

4. Operation control signal

No-voltage contact or open collector signal input

During pump operation

I -8 I

During setting

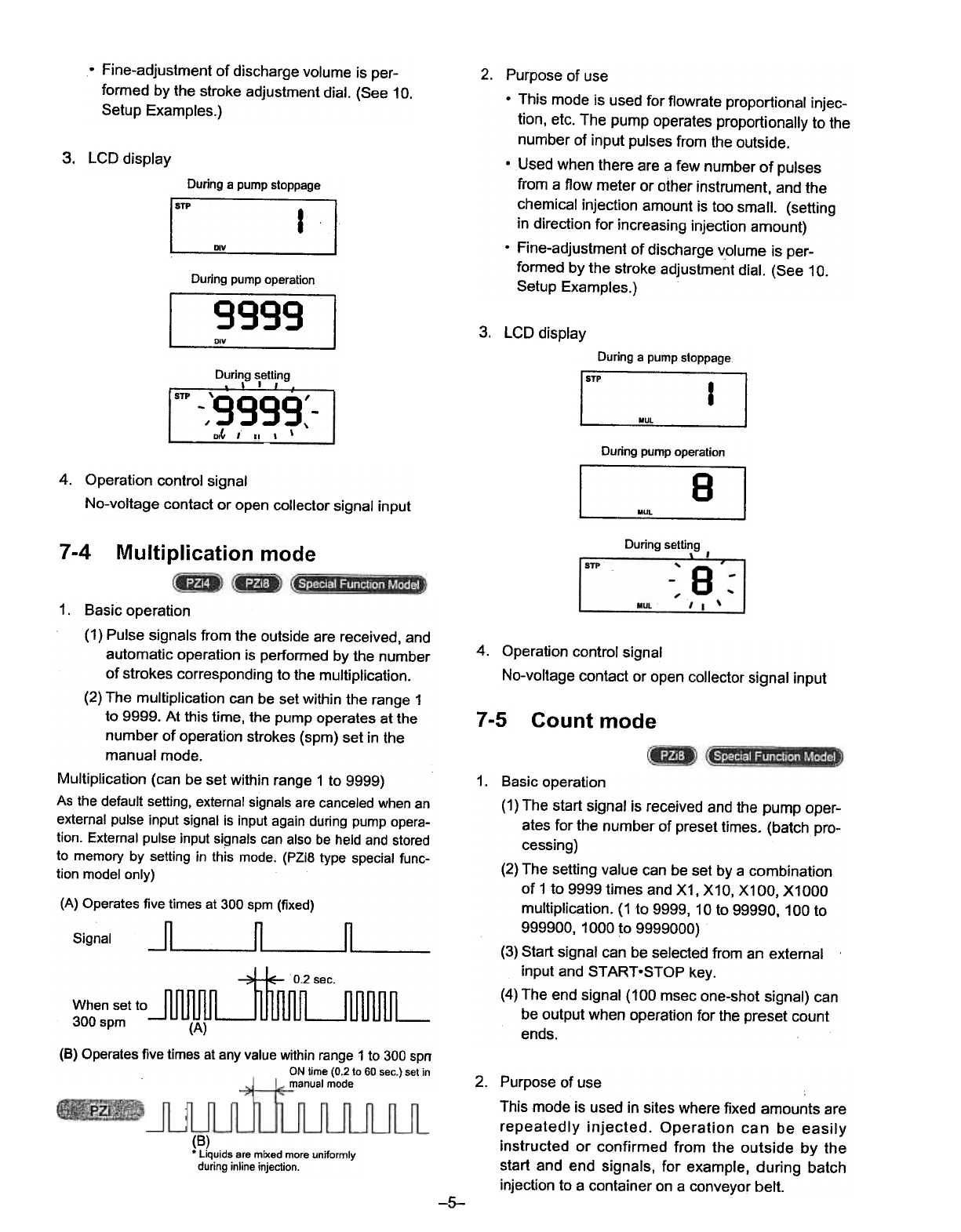

7-4 Multiplication mode

1. Basic operation

(1) Pulse signals from the outside are received, and

automatic operation is performed by the number

of strokes corresponding to the multiplication.

(2) The multiplication can be set within the range 1

to 9999. At this time, the pump operates at the

number of operation strokes (spm) set in the

manual mode.

Multiplication (can be set within range 1 to 9999)

As the default setting, external signals are canceled when an

external pulse input signal is input again during pump opera-

tion. External pulse input si~nals can also be held and stored

to memory by setting in this mode. (PZi8 type special func-

tion model only)

(A) Operates five times at 300 spm (fixed)

SignaI -] Jl jnnnnn ~no:sec. nnnnn

When set toJUUUULJUUUULJUUUUL

300 spm (A)

(8) Operates five times at any value within range 1 to 300 spn

ONlime (0.2 to 60 sec.) setin

manualmode

4. Operation control signal

No-voltage contact or open collector signal input

7-5 Count mode

1. Basic operation

(1) The start signal is received and the pump oper-

ates for the number of preset times. (batch pro-

cessing)

(2)The setting value can be set by a combination

of 1 to 9999 times and X1, X10, X100, X1000

multiplication. (1 to 9999, 10 to 99990,100 to

999900, 1000 to 9999000)

(3)Start signal can be selected from an external

input and START-STOP key.

(4)The end signal (100 msec one-shot signal) can

be output when operation for the preset count

ends.

2. Purpose of use

This mode is used in sites where fixed amounts are

repeatedly injected. Operation can be easily

instructed or confirmed from the outside by the

start and end signals, for example, during batch

injection to a container on a conveyor belt.

(B)

.Liquids are mixed more uniformly

during inline injection.

-5-