9

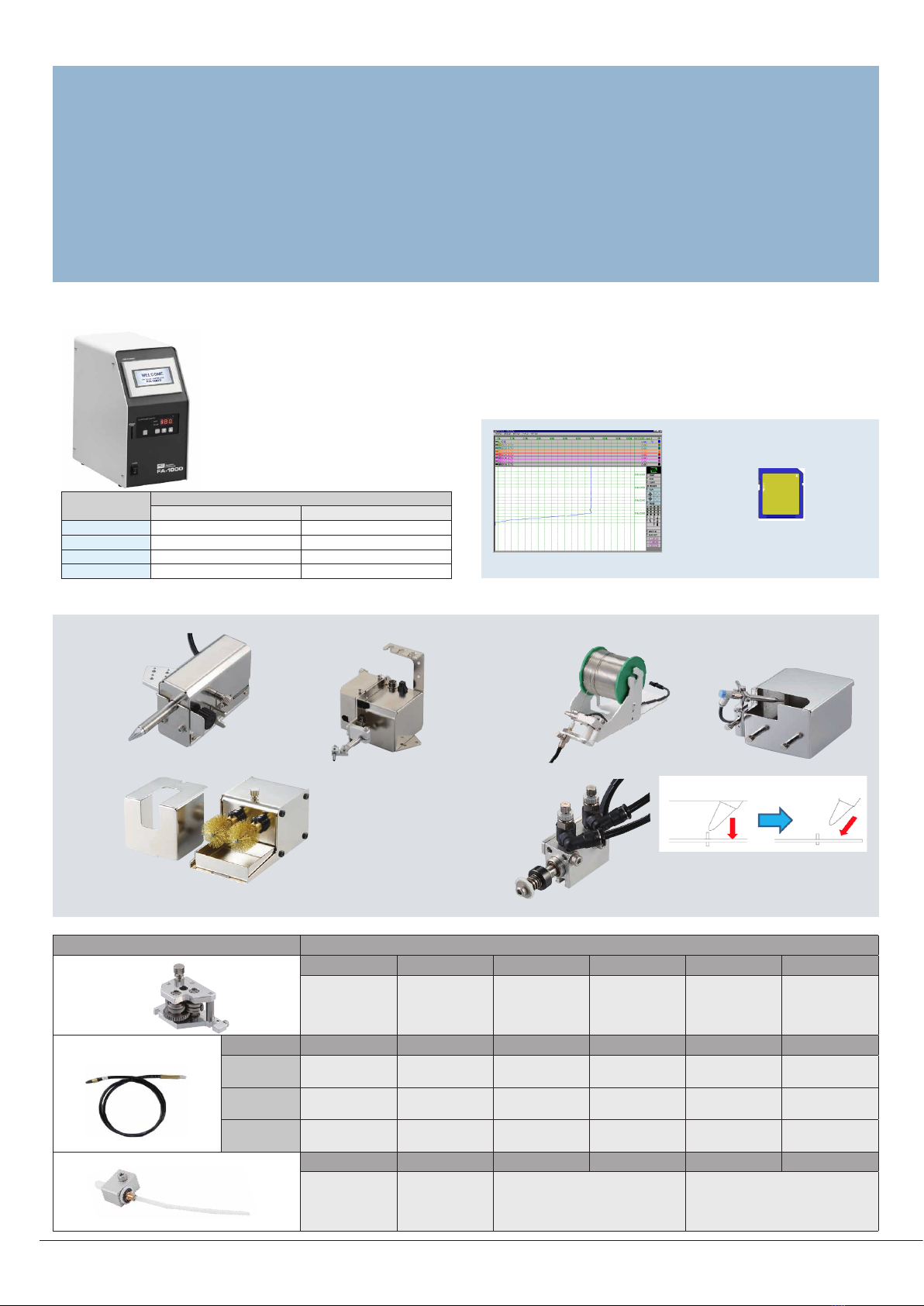

FA-3204 FA-3304 FA-3404

Axis Type Regular 4-Axis, Optional 2-Axis (Max. 6-Axis)

Operating Range

X-Axis 200 mm 300 mm 400 mm

Y-A xis 200 mm 320 mm 400 mm

Z-A xis 50 mm 100 mm 150 mm

R-Axis ±90°(Max.±360°) ±90°(Max.±360°) ±90°(Max.±360°)

Shape Cantilever type Gate type Cantilever type

Maximum Portable Load (Workpiece) 7kg 15kg 15kg

Maximum Speed

<PTP Movement>

X, Y-Axis 700 mm/sec 900 mm/sec 900 mm/sec

Z-A xis 250 mm/sec 400 mm/sec 400 mm/sec

R-Axis 600°/sec 900°/sec 900°/sec

Maximum Speed

<CP Movement>

X, Y, Z Combined

Speed 600 mm/sec 850 mm/sec 850 mm/sec

Repeatability

X, Y-Axis ±0.01 mm

Z-A xis ±0.01 mm

R-Axis ±0.008°

Work Size (Maximum Size of Jig) 200 mm×145 mm 300 mm×275 mm 400 mm×355 mm

Teaching Method Remote teaching (JOG)/ Manual Data Input (MDI)

Teaching System Direct teaching using the optional teaching pendant

Off-line teaching with optional software from a PC

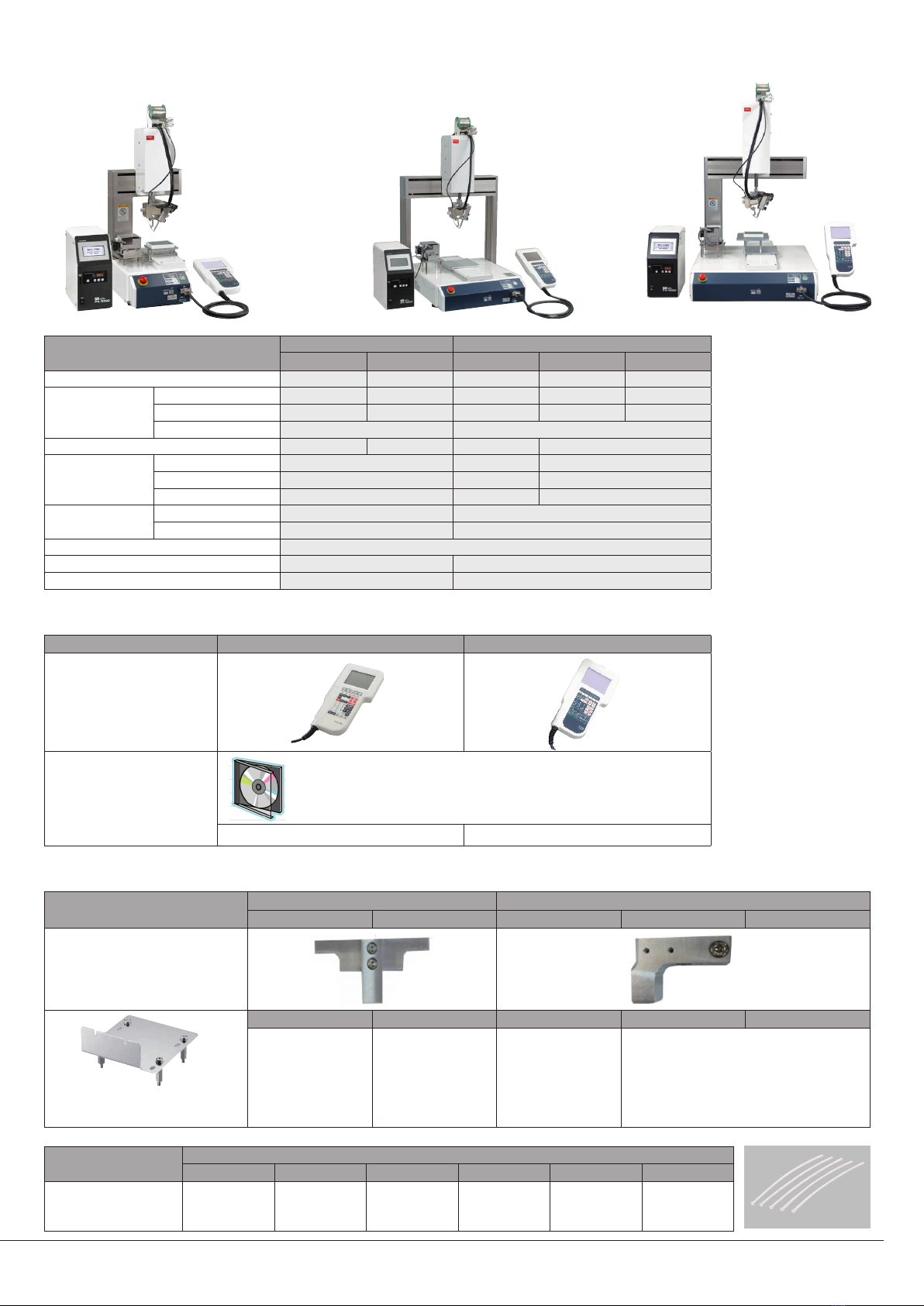

Teaching Pendant

Display

Measurement Units mm, inch

Languages

Switch back and forth among these languages: Japanese, English,

German, Italian, Spanish, French, Korean, Simplied Chinese,

Traditional Chinese, Czech, Vietnamese.

Program Capacity 999 programs

Data Capacity Up to 32,000 Points

External

Input/Output

I/O-SYS (Standard) 16 Inputs, 16 Outputs

I/O-1 (Standard) 8 Inputs, 8 Outputs (including 4 relay outputs)

*For connecting with optional (FA-1000TCM)

I/O-MT/I/O-S

I/O-MT: External Motor Control (Option)

I/O-S: For connecting with interlock device such as area sensor

(Option)

COM1 (Standard) RC-232C for external device control, COM commands

COM2 (Standard) RC-232C for external device control 9 (for connecting with FA-1000)

COM3 (Standard) RC-232C for external device control

MEMORY (Standard) For USB memory connection

LAN (Standard)

For PC connection via the Ethernet (10BASE-T/100BASE-TX)

(Robot control via control commands, Connection to (optional) PC

software)

Simple PLC Function Max. 100 programs, Up to 1,000 steps/1 program

Drive Method 5 phase pulse motor drive

Control Method PTP (Point to Point) control, CP (Continuous Path) control

Interpolation 3-dimensional linear and arc interpolation

Power Source AC100~120V (Single Phase)

AC220~240V (Single Phase)

Power Consumption 200W

Operating

Enviroment

Temperature 0~40°C

Relative Humidity 20-90% (Without condensation)

Elevation Up to 1,000m

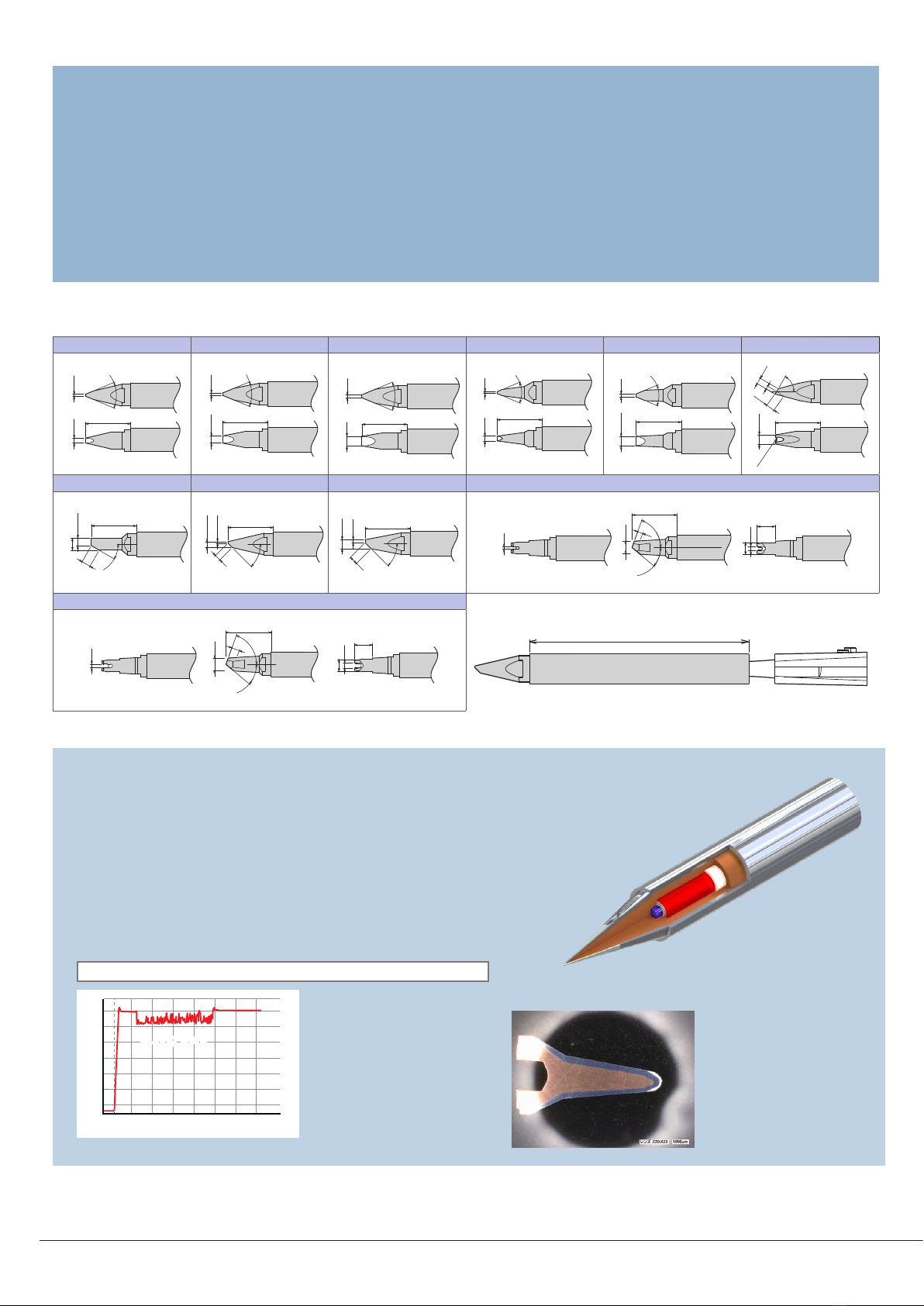

Control Unit

FA-1000

Rated Voltage AC 110-120V, 220-240V 50/60Hz

Power Consumption 170–200 W

Number of Soldering Programs 256 programs

Tip Temperature Range 50−450˚C

Tip Temperature Preset 6 settings

Input Air Pressure Dry Air 0.4 –0.5 MPa

Alarm Display Heater break / Temperature sensor break / Solder

clogging / Solder lacking etc.

Dimensions 140(W) x 280(H)x 240(D)mm

Weight 8.6 kg

Solder Feeder Unit

FA-1000FD Solder Diameter ø0.5 ø0.6 (ø0.65) ø0.8 ø1.0 ø1.2 ø1.6 mm

Soldering Unit

FA-1000SD

Heater Voltage / Power 24 V / 150 W

Length 145mm

Weight Approx. 950 g (Solder Feeder Unit included)

FA-1000 System Standard Specications

FA-1000 System Robot Standard Specications

FA-3204

FA-3304

FA-3404