on the sides.

6. Transom late with 4-socket inbus screw connection:

Attach the transom plate to the four fastening tongues using the inbus screws provided. The screws

are guided with an attached circlip and an attached washer from the inside out through the

mounting tabs in the transom plate and first by hand in the back pressed nuts. Please make sure

that the screws can be easily screwed into the nuts. Make sure that there is a circlip and a washer

under each screw head. The final fixing is done with the help of the included Allen key. Tighten the

screws well hand-tight, do not use brute force when screwing. There is an additional little spacer

plate included in the delivery package which you have to use if you want to install an engine at the

transom plate. This little spacer plate is placed under the motor bolting.

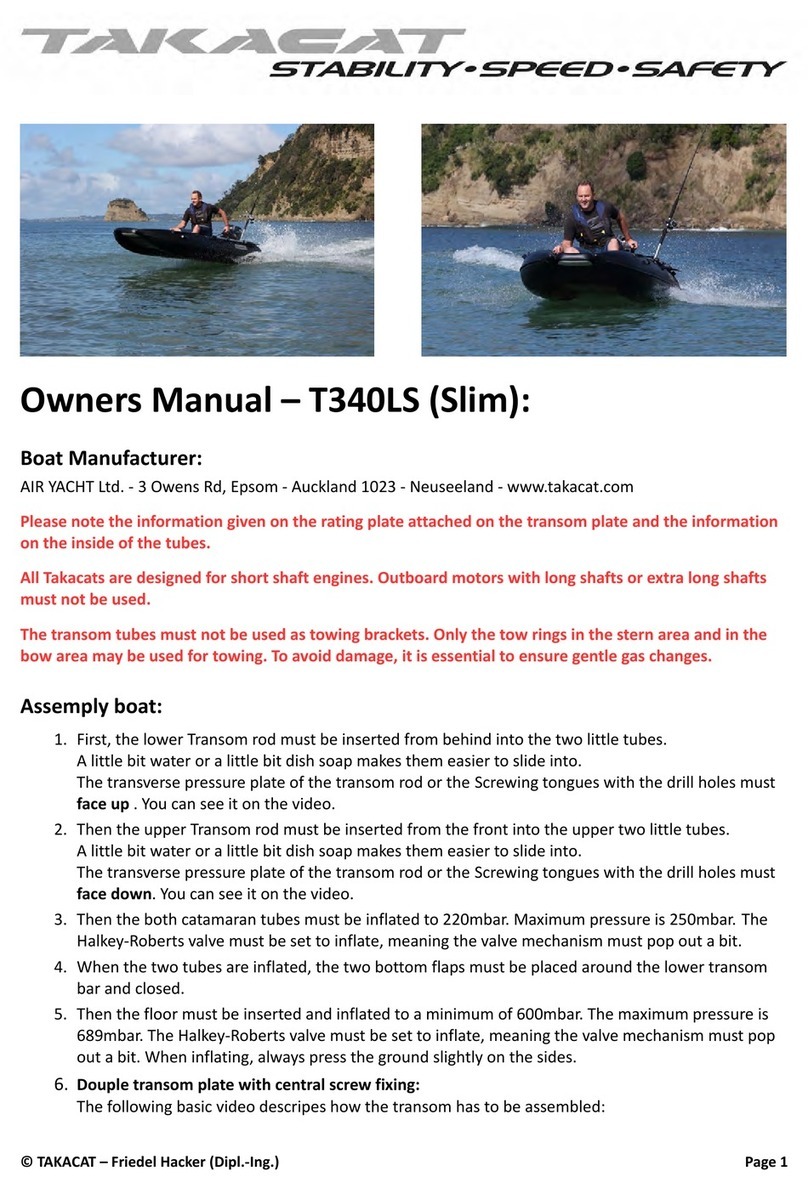

Dou le transom late with central screw fixing:

The following basic video descripes how the transom has to be assembled:

https://www.youtube.com/watch?v=BTRTezVRcF0&feature

Place the smaller transom plate with the rating plate from the front onto the stainless steel

receptacles of the transom tubes and insert the central fastening nut through the attachment hole

with a slotted spacer. Insert the rear transom plate also the fixing screw and coat the last threads of

the fixing screw, e.g. light with transparent lubricant from Liqui Moly. Then hand-tighten the ring

nut with a shim under it. Fix the central transom mounting with a 17 mm socket wrench and a lock

nut for the ring nut. Do not use brute force when screwing. Do not use brute force when screwing.

Lubricating the threads serves to revent the threads of the screw and ring nut from caking, for

which V4A stainless steel tends.

7. Inflate the included flat seat with 00mbar, position it where you need it. You can fixed it at the

inside rings.

8. Finaly the two oars must be assembled and mounted on the oarlocks and be fixed at the end.

9. The optional wheels are plugged into the corresponding brackets on the lower transom mount on

the left and right. The optimum position is given when the wheels are inside. This ensures that the

maximum left-to-right deflection is available to a possibly installed outboard motor when switching

to the floating position. The wheels must be inflated so that they have a correct rolling behavior and

float in case of loss in the water or at the dock and do not sink.

10.The optional fishing rod holders are inserted from the inside into the left and right retainers of the

upper transom mount until the interlock heads indicate proper seating.

Maintenance:

Regularly check valves, stitching, ribbons, hooks, screws and nuts on your Takacat boat. Pontoons are more

alive than a plastic hull and their constant movement can cause fatigue damage. It is important to keep the

pontoons sufficiently inflated. Under-inflation will cause more water resistance and thus slowing. Regularly

check the pontoon mounts to the transom and hull and other joints in the tubes. In smaller inflatables

between any loose floorboards and pontoons, it is important to keep areas clean from dirt and debris that

could rub and wear down the pontoon.

Cleaning basically requires no more than a cleanser, a brush and a sponge for managing the cleaning and

maintenance of the boats pontoons.

Soap: Mix the soap with water according to instructions on the package. Scrub the pontoons with a sponge

or scrubbing brush. Rinse off with water. Never use high pressure when cleaning the boat, it can damage

the stitches or fabric of the pontoons, etc.

Storage:

TAKACAT Sport or Lite inflatables can be stored either inflated or in a storage case. When stored in a bag,

the bag must be dry. Take this opportunity to clean sand etc. from between the floorboard and pontoons.

When it comes to winter, there are some basic tips. The boat does best not to stand in freezing

temperatures, although it is not a must to have it indoors. If you cover the boat, do not use a vinyl tarp and