I

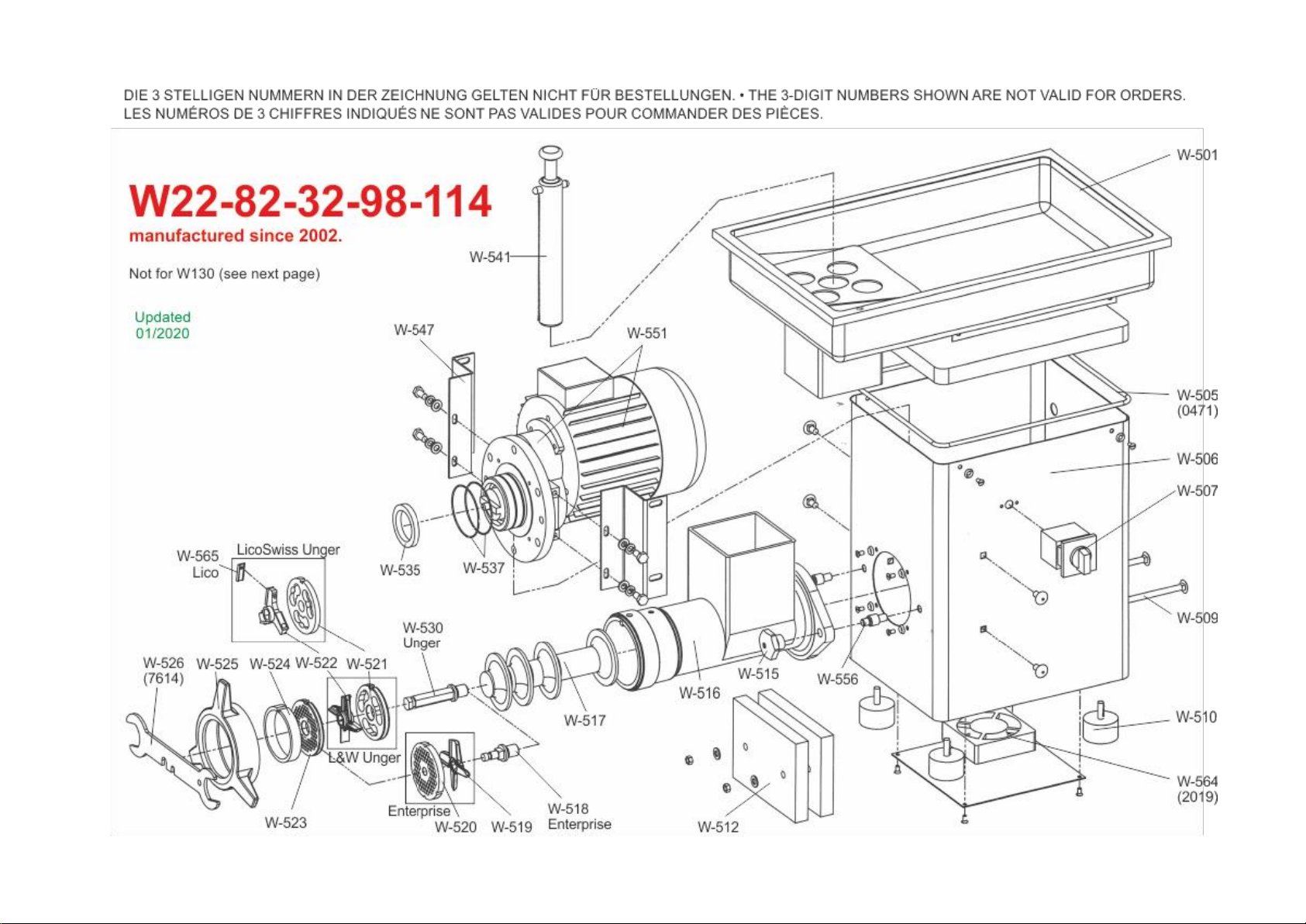

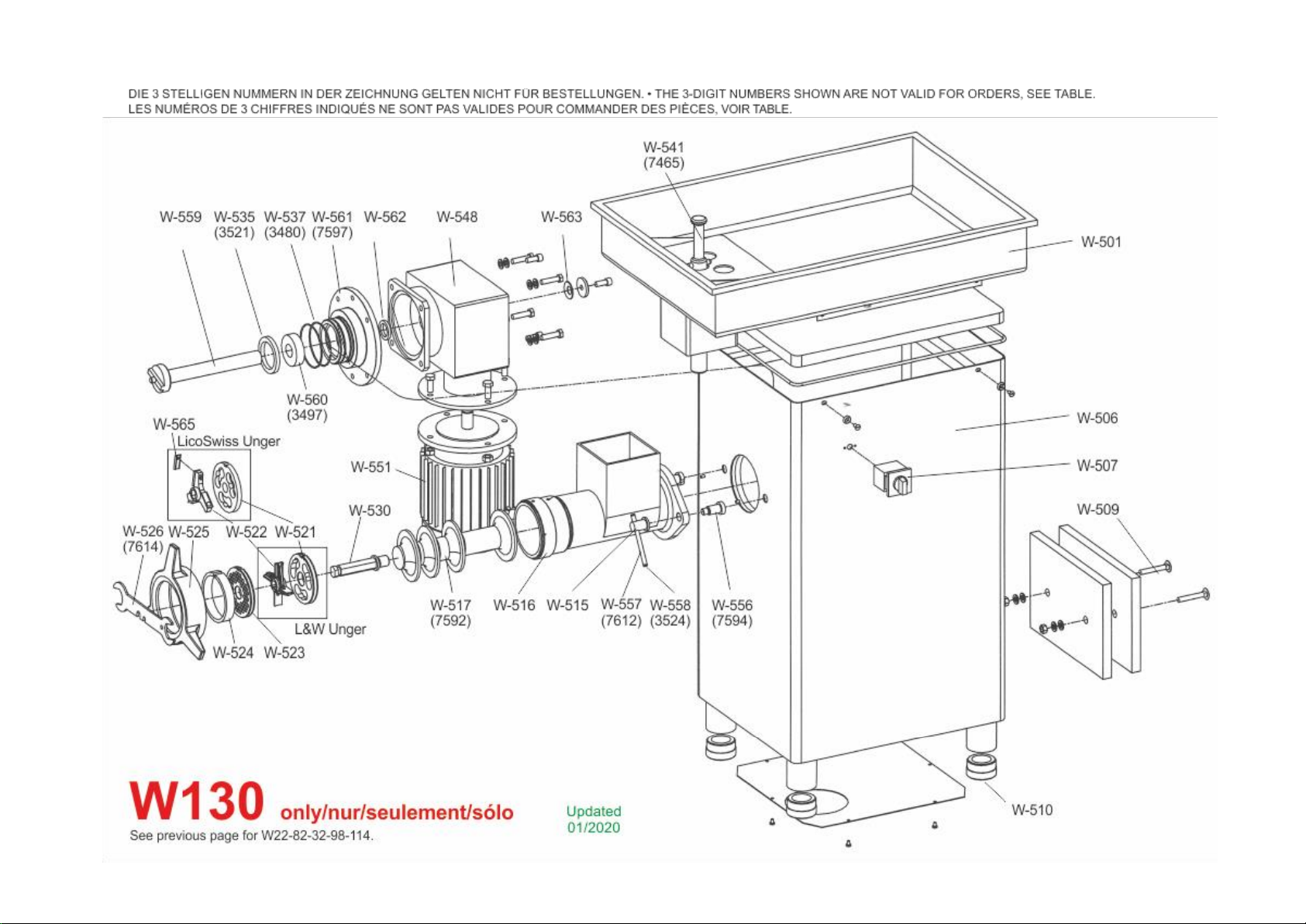

W22 • W82 • W32 • W98 •W114 •W130

-ORIGINAL -

Labeled Diagrams .............................................................................................................................II

Spare Parts List ................................................................................................................................IV

Main Components .........................................................................................................................VII

Electric Schemas ..........................................................................................................................VIII

Drawings ..............................................................................................................................................IX

EU-Declaration of Conformity (CE)........................................................................................XII

Installation and Operating Manual................................................... EN 17

Please read and comply with this original manual prior to the initial operation of your machine and store it for

later use or subsequent owners.

Notice d’Installation et d’Utilisation.................................................. FR 17

Lire cette notice originale avant la première utilisation de votre appareil, se comporter selon ce qu’elle requiert

et la conserver pour une utilisation ultérieure ou pour le propriétaire futur.

Installations- und Betriebsanleitung................................................. DE 17

Lesen Sie vor der ersten Inbetriebnahme Ihres Gerätes bitte diese Originalbetriebsanleitung, handeln Sie

danach und bewahren sie für späteren Gebrauch oder für Nachbesitzer auf.

Handleiding voor Installatie en Gebruik............................................ NL 17

Lees deze originele gebruiksaanwijzing door voordat u uw apparaat voor de eerste keer gebruikt, handel

ernaar en bewaar het voor later gebruik of voor volgende eigenaars.

Manuale di installazione e uso ......................................................... IT 17

Prima del primo utilizzo della macchina, leggere questo manuale originale, agire secondo le sue indicazioni e

conservarlo per un uso successivo o per un altro proprietario successivo.

Manual de Instalación y Utilización.................................................. ES 17

Antes del primer uso de su máquina, lea este manual original, actúe de acuerdo a sus indicaciones y guárdelo

para un uso posterior o para otro propietario posterior.