1SAFETY AND WARNINGS ......................................................................................................................3

2WARRANTY .............................................................................................................................................3

3PRECAUTIONS AND HAZARDS ............................................................................................................4

4INSTALLATION........................................................................................................................................4

4.1 IMPORTANT..........................................................................................................................................4

4.2 UNPACKING .........................................................................................................................................4

4.3 BATH LIQUID.........................................................................................................................................6

4.4 DRAIN BATH FLUID................................................................................................................................6

4.5 BATH FLUID LEVEL................................................................................................................................7

4.6 BATH FLUIDS........................................................................................................................................9

5COOLING................................................................................................................................................12

5.1 CONNECTING .....................................................................................................................................12

6INTRODUCTION.....................................................................................................................................13

6.1 GENERAL...........................................................................................................................................13

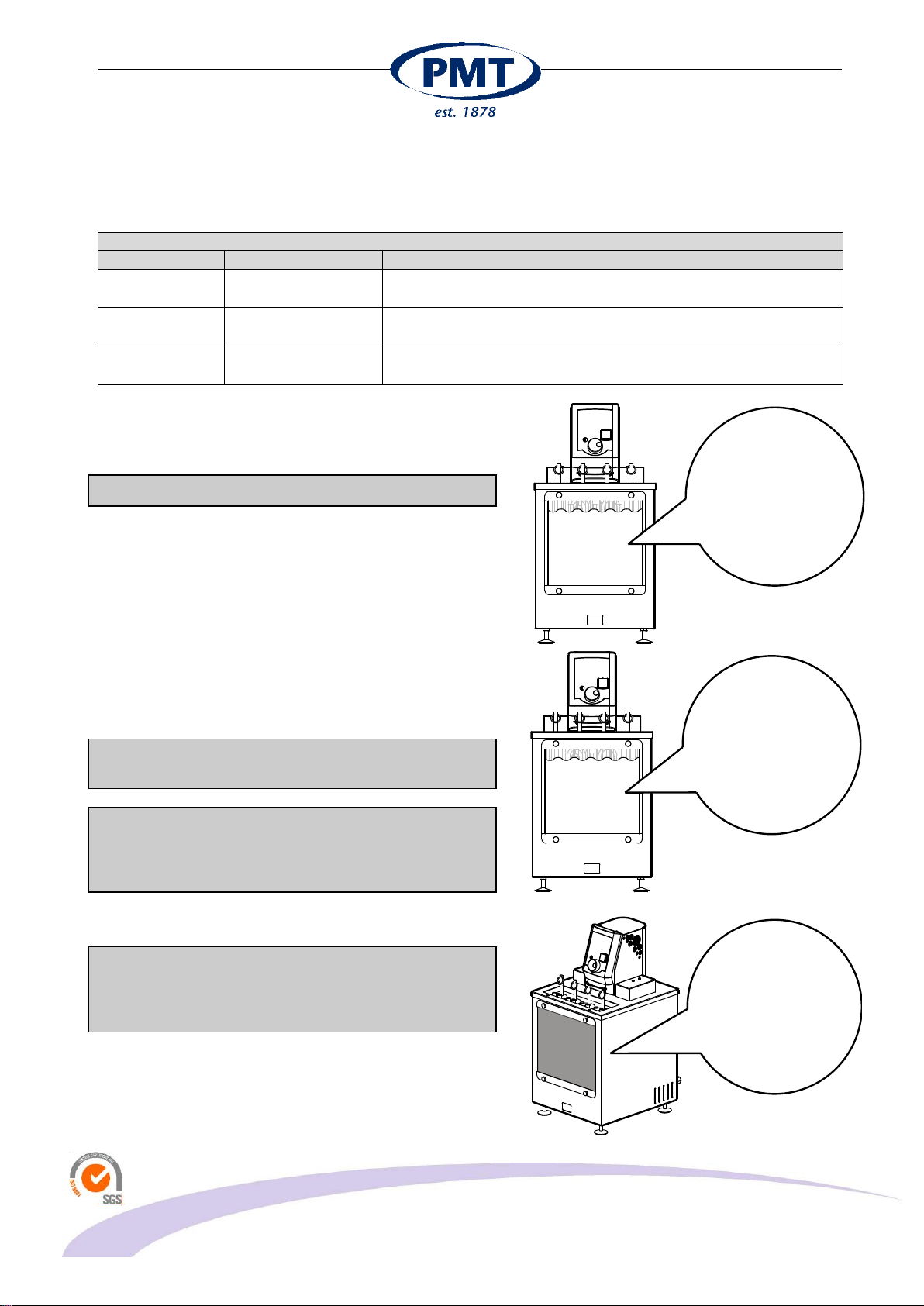

6.2 CONSTRUCTION .................................................................................................................................13

6.3 STIRRER............................................................................................................................................13

6.4 TEMPERATURE CONTROL AND SETTING................................................................................................13

6.5 SAFETY SYSTEMS...............................................................................................................................14

6.6 ADJUSTING THE MECHANICAL OVER-TEMPERATURE PROTECTION THERMOSTAT .....................................14

6.7 FRONT PANEL....................................................................................................................................14

6.8 OVERVIEW MENU ITEMS......................................................................................................................15

6.9 SAFETY THERMOSTAT.........................................................................................................................15

6.10 DISPLAY.........................................................................................................................................16

7OPERATING THE SYSTEM...................................................................................................................17

7.1 QUICK START.................................................................................................................................17

8MENU ITEMS..........................................................................................................................................17

8.1 PID SETTINGS....................................................................................................................................20

8.2 MANUAL TUNING.................................................................................................................................21

8.3 PRECISION OF CONTROL.....................................................................................................................22

8.4 LONG TERM STABILITY ........................................................................................................................22

8.5 HOMOGENEITY AND T.......................................................................................................................24

9RS232 COMMANDS...............................................................................................................................25

10 TROUBLE SHOOTING.......................................................................................................................25

10.1 APPLICATION ERRORS.....................................................................................................................25

10.2 BATH MALFUNCTION........................................................................................................................25

10.3 PROBLEMS WITH SET POINT.............................................................................................................25

10.4 FAULTY TEMPERATURE READING OR TEMPERATURE OFFSET .............................................................25

10.5 BATH TEMPERATURE DOES NOT BECOME STABLE .............................................................................26

10.6 BATH DOESN'T REACH SP...............................................................................................................26

11 SPARE PARTS LIST ..........................................................................................................................27

12 DIMENSIONS......................................................................................................................................27

13 EC DECLARATION OF CONFORMITY.............................................................................................28

14 DISCLAIMER ......................................................................................................................................29