RETROFIT INSTALLATION GUIDE

Page 6

US

LED

|

6807

PORTWEST

DR

|

HOUSTON,

TX

77024

|

T

866

972

9191

|

F

713

972

9393

|

[email protected] |

www

.usled.com

Updated 05.19.11

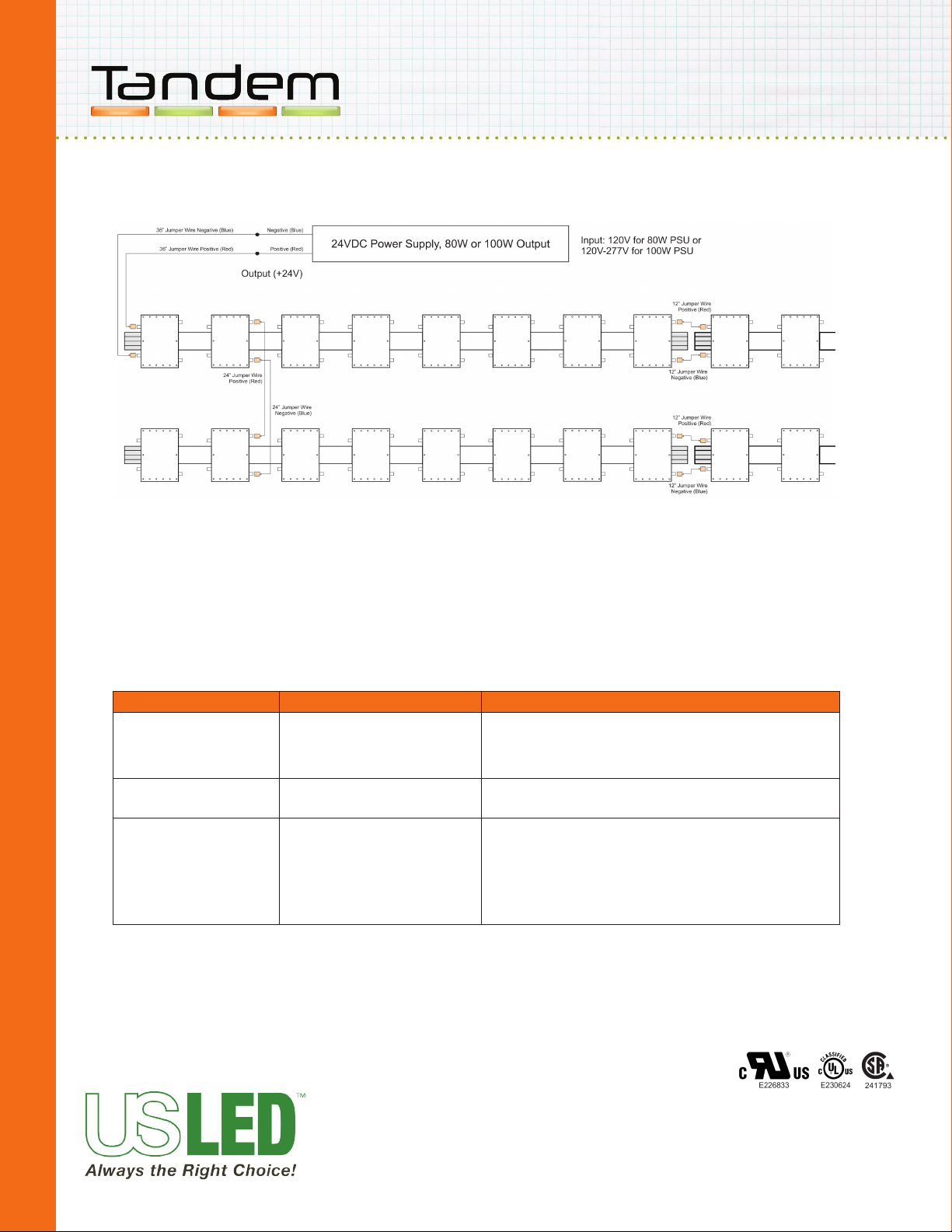

G1-14-24-4W

G2-14-24-4W

Model Number

Power Supply Loading

4

2

27

13

Feet / 80W

Min Max

4

2

27

13

Feet / 100W

Min Max

8. Secure the loose mounting bracket to the wire raceway using a self drilling screw (Figure 12).

9. Secure Tandem unit to mounting bracket using self drilling screw positioned approximately ½” from the end.

10. Repeat steps 7, 8 and 9 for the remaining Tandem units.

11. Install and connect power supplies to source in accordance with National Electrical Codes and any applicable

local codes.

12. Refer to US LED data sheet for proper power supply loading.

13. Use 36” Quick Connect Jumper Wires between Power Supply and Tandem unit module tabs (minimum 1

18AWG wire with 1 20AWG; maximum 4 16AWG with 1 20 AWG). Red wire to the positive “+” tab, Blue wire to

the negative “-” tab of the Tandem module. See Wiring Diagram on Page 7.

14. Use 6” Quick Connect Jumper Wires to energize Tandem units within the same row/column. Red wire to the

positive “+” tabs, Blue wire to the negative “-” tabs of the Tandem modules. See Wiring Diagram on Page 7.

15. Use 24” Quick Connect Jumper Wires to energize adjacent row/column of Tandem units. Red wire to the posi-

tive “+” tabs, Blue wire to the negative “-” tabs of the Tandem modules. See Wiring Diagram on Page 7.

16. Cut wires between modules to achieve the desired amount of modules per power supply (per loading chart).

Place wire nut over cut end of wire.

17. Repeat steps 11 through 16 until system is completed.

18. Attach cabinet sign face.

19. Energize xture.

INSTALLATION INSTRUCTIONS (cont)

Figure 12: Securing mounting bracket