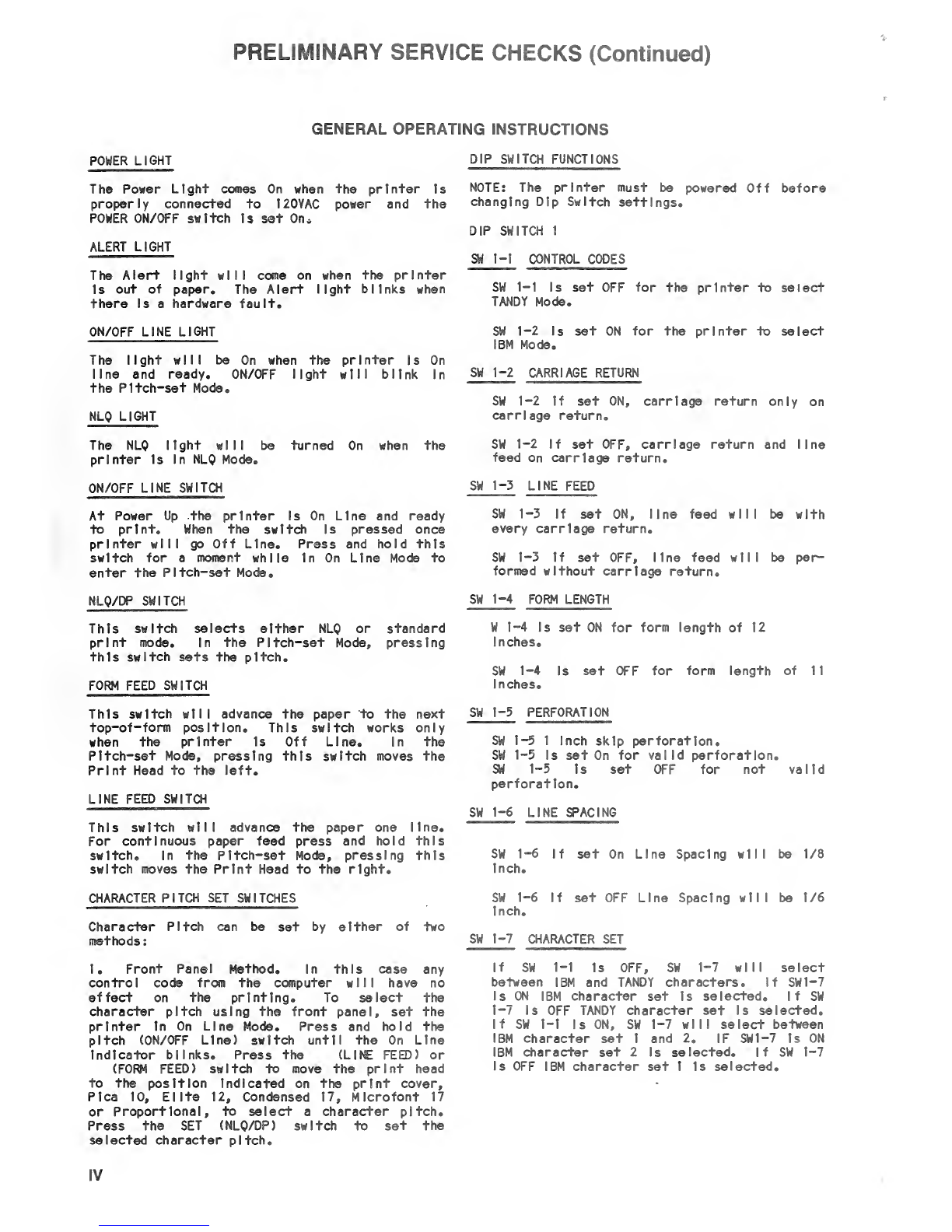

PRELIMINARY SERVICE CHECKS (Continued)

SELF-TEST

To run self-test, press and hold the LINE FEED

switch while turning the powsr switch on. The

printer will print the self-test In standard

font. If the NLQ switch is pressed Instead of

the LINE FEED switch, the test will be printed

In the Quality font.

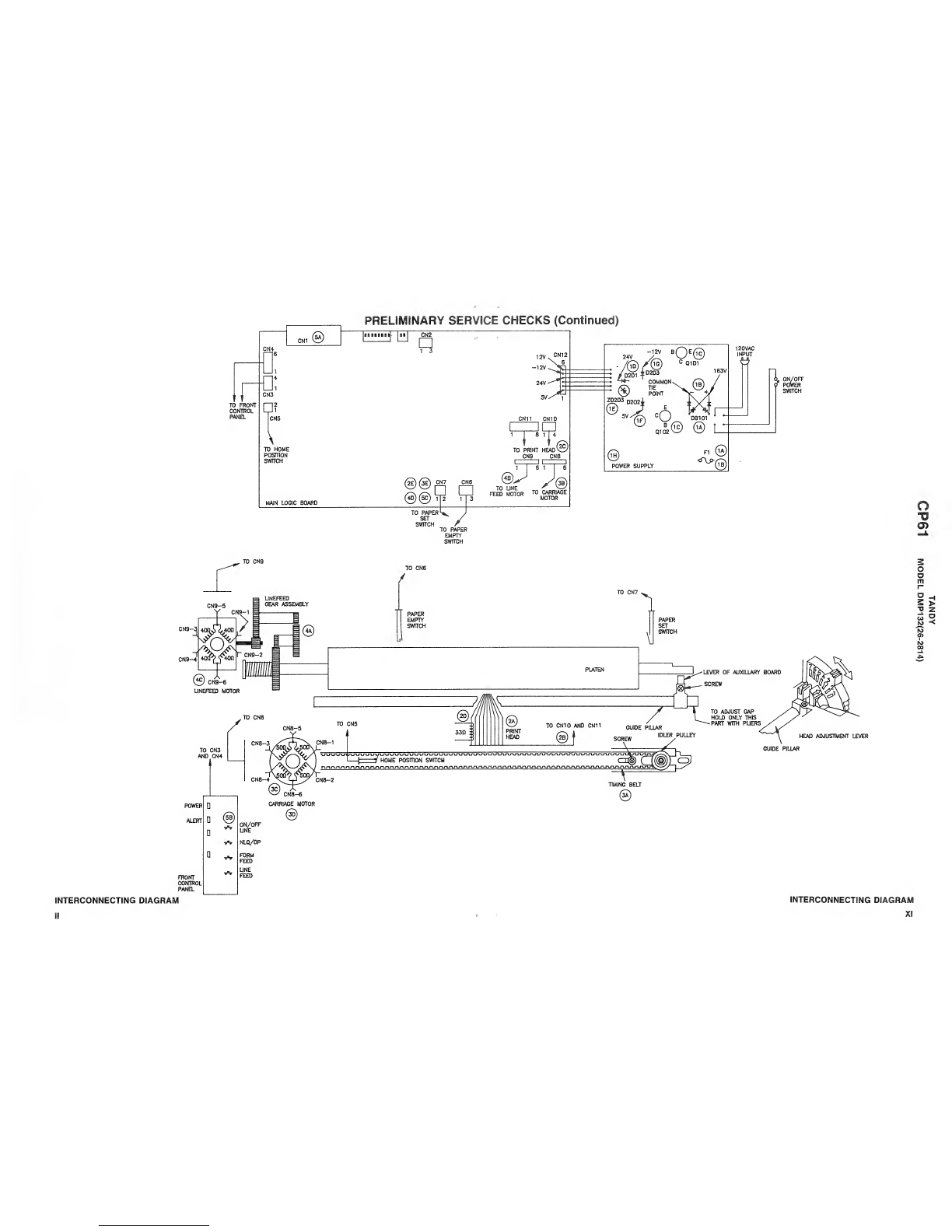

PRINT HEAD PLATEN GAP ADJUSTMENT

MISCELLANEOUS ADJUSTMENTS

holding the auxiliary board. Push the lever

towards the platen slightly while holding the

guide pillar (front shaft of the carriage

assent Iy). Tighten the screw then run the

self-test again and check the print quality.

On the right hand side of the platen Is the

Print Head adjustment lever. This lever

allows adjustment of the Print Head according

to paper thickness variations. When the gap

Is too narrow It can cause smudging In the

printout, paper damage at the left or the

right margin, or Inaccurate line feedSrig„ If

the gap Is too wide It can cause light

printing or missing characters. When the Head

adjustment lever Is pushed all the way towards

the platen it Is set to position (1). When

the lever Is pulled away from the platers it Is

set to position (7).

Perform the self-test printing In standard

character mode, when the Head adjustment lever

Is at positions (2), (3) and (4). If smudging

appears at position (2), loosen the screw

If printing Is light or missing some

characters at position (4) loosen the screw

holding the auxiliary board. Pull the lever

slightly towards the front of the printer

while holding the guide pillar. Tighten the

screw. Run the self-test and check the print

quality. The adjustment Is complete when the

print quality Is satisfactory.

TIMING BELT TENSION ADJUSTMENT

The tension of the timing belt can be adjusted

by moving the position of the Idler pulley. on

the right hand side of the timing belt.

Loosen the screw, then press the Idler pully

outward to put tension on the timing belt,

tighten the screw to hold the Idler pulley

plate block In place. Check the widths of

printed characters at the first and second

columns. If the widths of characters are

improper it Is required to readjust the

tension of the timing belt.

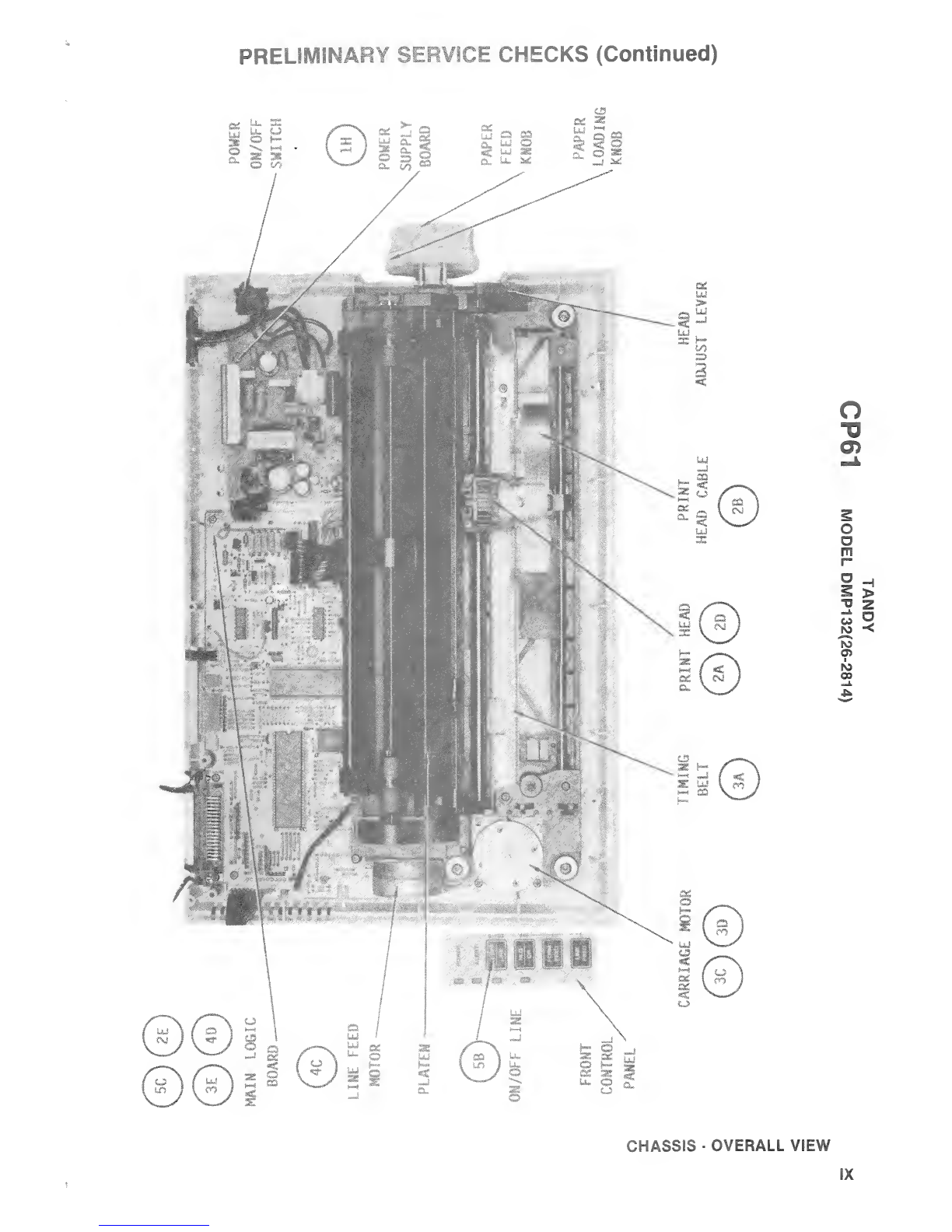

TOP CABINET REMOVAL

DISASSEMBLY INSTRUCTIONS

PRINTER MECHANISM REMOVAL

Open and remove the printer cover. Remove the

paper rack if Installed® Remove two screws

from the front and three screws from the back

of the printer. Carefully lift up the top

cabinet and unplug connectors CN2, C83 and

CN4. To unplug the connectors push down the

connector, then pull the leads out of the

connector. Remove the Top Cabinet frosn the

Printer.

FRONT PANEL REMOVAL

Remove the Top Cabinet, then press four tabs

and remove the Front Panel from the Top Cabi-

net.

MAIN LOGIC BOARD REMOVAL

Remove the Top Cabinet. Remove four screws

fastening the Main Logic Board to the Bottom

Cabinet. Disconnect connectors CN5 thru CM12.

Lift the Main Logic Board out of the Bottosr,

Cabinet.

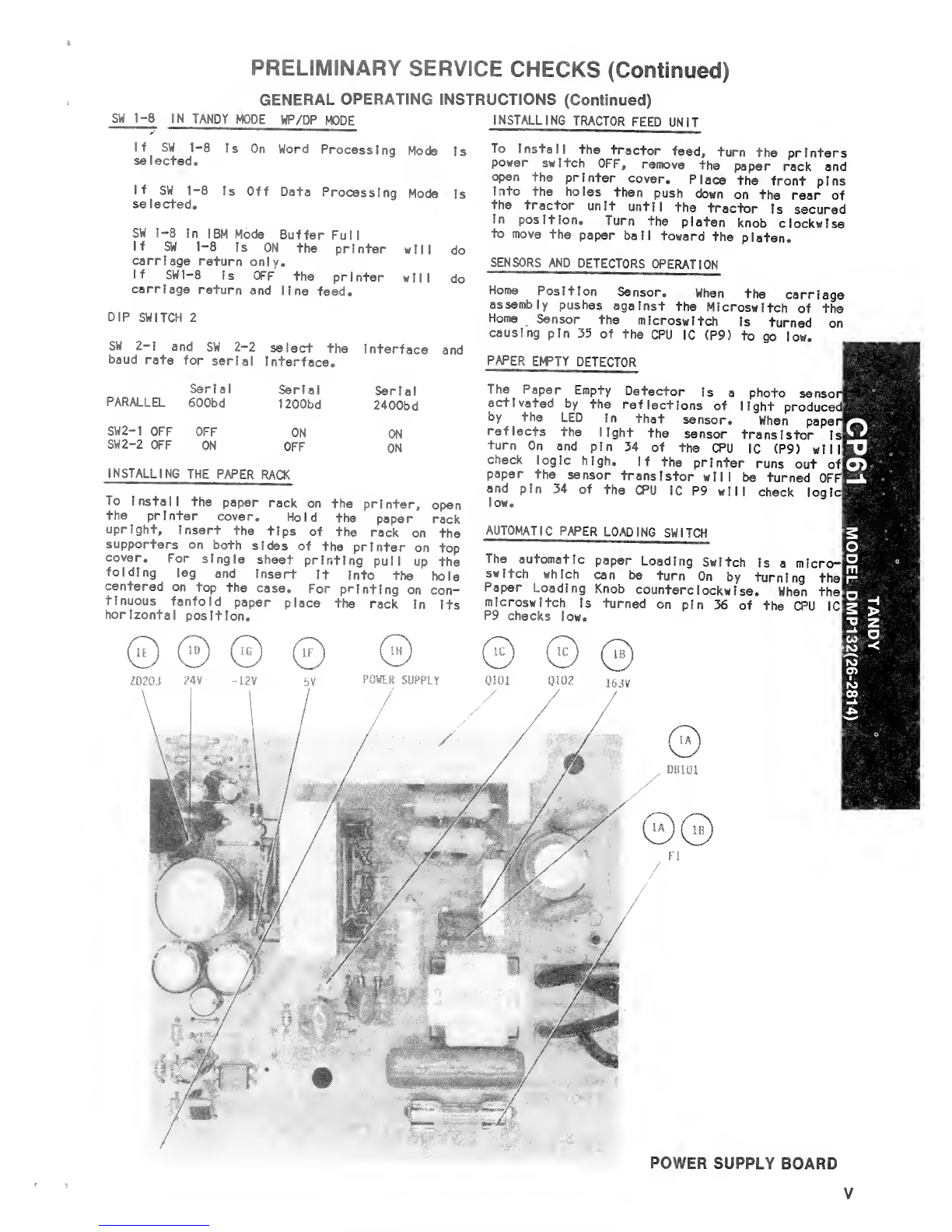

POWER SUPPLY BOARD REMOVAL

Remove the Top Cabinet. Remove two screws

holding the Power Supply board. Slide On/Off

switch up out of Its slot in the cabinet

bottom. Disconnect connector CN12. Lift the

Power Supply Board out of the cabinet.

Remove the Top Cabinet. Remove four screws

holding the Printer Mechanism to the cabinet

bottom. Disconnect connectors CN5 thru CN1 1

from Main Logic Board. Lift the mechanism out

of the printer cabinet bottom.

CARRIAGE MOTOR REMOVAL

Remove the Top Cabinet. Remove two screws

holding the carriage motor. Slide the

carriage motor to the left and disconnect

connector CN8. Remove the carriage motor from

the mechanism.

LINE FEED MOTOR REMOVAL

Remove the tractor, lift it from the rear and

pull It upward. Remove three screws which

hold the line feed gear box. Carefully slide

the line feed motor upward to remove it. Dis-

connect the line feed connector CN9 from the

logic board. Remove the line feed motor from

the printer.

PRINT HEAD REMOVAL

Remove the metal plate FBC guide securing the

print head, using aflat screw driver. Dis-

connect the flexible cable of the print head.

PtilS the print head toward the front to remove

:- -

y?